I forgot to post two pictures in the last post.

The first one is the right side of the trigger and stock housing:

Again, we're just looking at the overall fit and finish of the parts here. The pistol grip panels are beautifully shaped and appear to be beech. The entire steel lower is machined and equally well sculpted. "OGIEN" is Polish for "FIRE".

The second one shows the butt plate to wood fitment. Zero gaps:

The bump in the middle is the rivet holding the rotating trap door in place. Pull down on the spring tab at the bottom and the door pivots 90 degrees. This allows you access to remove the recoil spring (not necessary for normal cleaning) and to remove the cleaning kit.

The cleaning kit that came with the rifle is on the left and a NOS one is wrapped up on the right:

Here, we see both opens showing all the goodies inside:

For the picture, I've placed everything on the kit I use in the same positions as the NOS kit. These were dirt cheap at first. Then, as parts started drying up, many vendors pirated the spare firing pin, extractor, and extractor spring out of the kits and selling them separately. To me that's dishonest. Anyway, the lesson to learn here is that you should buy this stuff when it originally hits the market and is plentiful. If you wait, you're only going to regret it later. Even though I only ever actually use one drum, I bought a pile of them at the time cheap. Now, they are around $70 when you rarely encounter them. Remember the lesson....

Here, I've laid out all the bits to show you just how extensive the kit is:

At top, left to right:

broken shell extractor, small scraper for the gas ports, spare extractor, above a partial spare firing pin (I'll explain below), spare extractor spring over a multi-purpose adapter (used to make a "T" handle among other things), large scraper for the gas cup.

** About the firing pin....... part of the semi-auto conversion kit was a small rod to be used as an intermediate firing pin between the slide hammer and the actual firing pin in the bolt. This intermediate firing pin was so poorly hardened (if it was hardened at all), it would begin to mushroom after just a few rounds. With continued use, it would lock in the bolt carrier and create a runaway firing situation. After playing with this for a while, I finally decided to omit it and fabricate my own by cutting part of the spare firing pin off, modify it, and use it as the intermediate firing pin. It worked perfectly and I just kept the remainder of the original spare firing pin instead of tossing it. I still have a spare in the NOS cleaning kit so it all worked out. **

Continuing on with the cleaning kit parts, row two, left to right:

pin punch, rod to be used with the aforementioned multi-purpose adapter to create a "T" handle, a multi-use tool used as a wrench, screwdriver, prying device, and other stuff, and finally, a bore cleaning jag. The actual cleaning rod is stowed along the left side of the receiver.

At the bottom is the steel case. It's held closed by a spring latch and can be used as a handle for the screwdriver if desired. The little spring fingers in the lid apply pressure to all the contents when stowed to keep them from rattling. The entire thing is a sweet little box of efficiency!

We'll finish this up by looking at some of the internal components.

First, we see the bolt sitting on the carrier with the locking flaps in the "locked" position. In this position, they would protrude into cutouts in the receiver, thus locking the action:

After ignition, as the bullet travels down the barrel, part of the gas is bled off to act on the gas piston, pushing the bolt carrier to the rear. As the carrier moves backwards, cam slot machined into it, interact with a lug protruding from the bottom of each locking flap, pulling them inwards against the bolt and out of the cutouts in the receiver. This allows the bolt/carrier assembly to continue to the rear, pulling the spent casing from the chamber as it does so. Here. we see the action unlocked with the flaps pulled inward against the bolt:

Here's the finish on the gas piston:

Nice, nice, NICE! The piston is, as far as the end user is concerned, permanently attached to the bolt carrier.

Machining on the top of the bolt carrier:

The bottle shaped area with all the inspection marks is where the bottom of the bolt rests. Behind that are the two camming slots that move the locking flaps inwards.

The serial number on the bottom of the bolt carrier appers to be engraved:

More very nicely stamped inspection marks on the bottom of where the gas piston and bolt carrier meet:

Again, we see the deep blue finish.

Inside surface of the locking flaps showing the electro penciled serial number and a number of inspection stamps:

These parts are bare steel with no finish.

Outside surface of the left locking flap turned upside down:

Front is to the right of the picture. It's rounded at the front so that it can pivot where it meets the bolt.

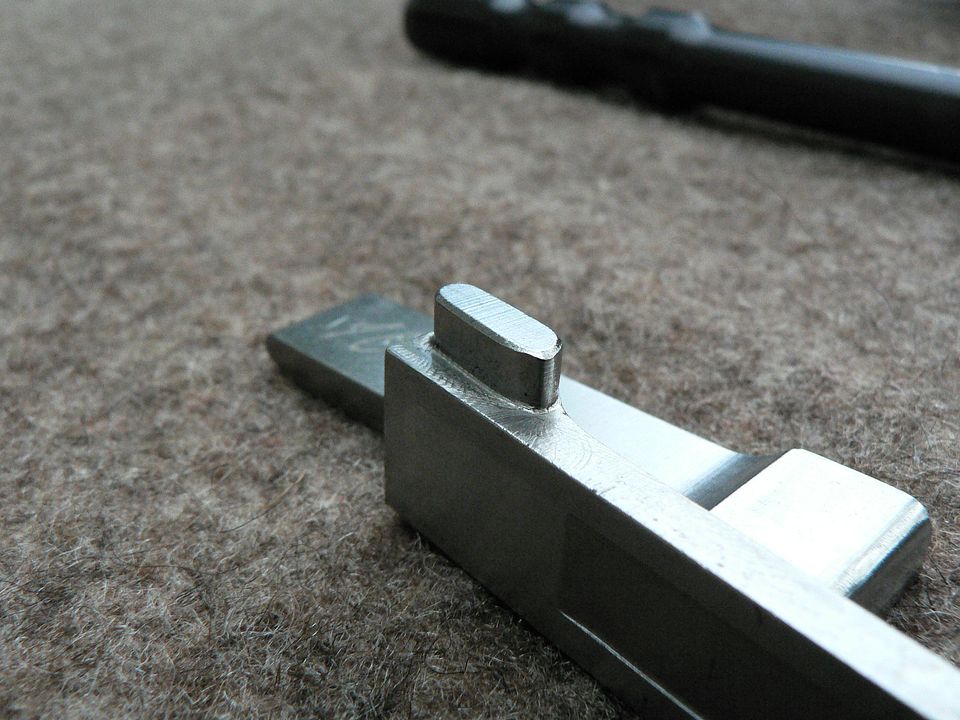

Detail of the lug that rides in the cam slot on the bolt carrier:

Not a crude cut or angle to be seen.

We'll finish up with the bolt. It's also in the white:

Bottom, showing the electro penciled serial number and a plethora of inspection stamps:

It wouldn't be Warsaw Pact is it wasn't covered in stamps!!

Left side of the bolt showing the recess for the locking flap. Bottom is at the top of frame and rear is to the left:

LOTS of work went into this part.

Top of the bolt showing the ejector slot and even more stamps:

Rear of the bolt showing the back of the firing pin:

And, finally, the front of the bolt:

And that's it, a quick look at some of the beautiful details on a typical Polish made RPD. While there are a fair number of stamped bits, most of this rifle is made the old school way out of finely machined and richly blued steel blocks. Compared to the RPK that replaced it, the RPD was an absolute work of mechanical art. Thankfully, the man who built it for me was VERY careful to preserve the original finish. It took him a while and he said that he'd NEVER build another RPD after his one time run. I was grateful to get this all those years ago and I hope to enjoy it for years to come. Maybe one day I'll do an in-depth look at all the details but this'll do for now. I just had it out for inspection and had some spare time today so I figured I'd share my fascination with it's overall Quality. Hopefully you enjoyed it as well. Thank you for your time!

Win a FREE Membership!

Win a FREE Membership!