Would start off by pulling the B/C, remove the bolt, than try just the carrier with key alone, to make sure gas tube is correctly aligned with carrier key. The gas tube enters the key when front of carrier is back about an inch from touching the barrel extension, carrier should slide all the way forward with ease to seat against barrel extension face, and when muzzle is aimed upwards, carrier should free fall back. If no, then gas tube needs to be tweaked at center of barrel, to align the back end of the gas tube correctly with the carrier key.

From there, take a good look at the extractor on the bolt, and make sure that its top edge releif side, is correclty back far enough with the ejector all the way inward home, that the live round can push the ejector open to allow the case rim to get past it, so case can seat to bolt face, with ejector snapped back home. Also, if o ring installed on the outside of the extractor spring, remove it.

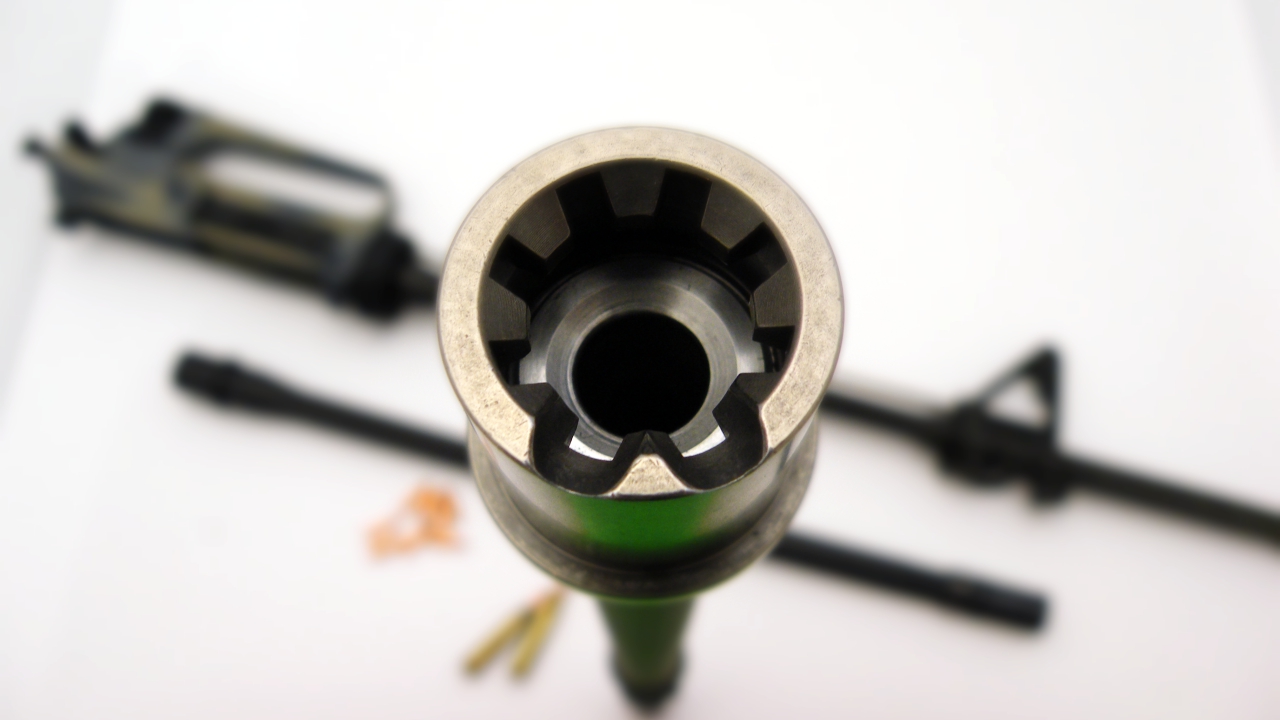

Here you can see that the entry ramp of the extractor is not far enough out compared to the bolt recess channel edge, the round hitting the outer flat, instead of in the ramp section, to be able to cleanly open the extractor load. Hence Ar is not a controlled feed, but as shoulder of case hits shoulder of chamber, this is the point that the extractor has to be forced open by the rim, so rim can seat against bolt face, and extractor snapped back on case rim, so bolt is able to rotate as well. Also, take a look at the rim releive cut on the extractor at the bolt face itself, with that edge being a touch too proud, and it finish worn off as well.

Here is an extractor that has the flat part of the entrance ramp beyond the bolt face recess wall edges, so as the rim is pressed down by the chamber shoulder at loading, rim tags the ramp section to easy push the ejector open so case rim can seat cleanly on bolt face, and extractor snap back over rim.

From here, need to check the entrance of the barrel chamber itself, since it not entry of chamber back edge not radius, then live round can scrap when entering the chamber. Here you can see that an attempt was made to radius the bottom of taper into the straight wall back edge of the chamber, but was not down deep enough, and left a sharp stepped edge for cases to scrap.

Another back of straight wall edge too sharp as well,

What the edge should look like,

Now with B/C still out, and upper shot gunned open, drop a round into the chamber, use a wooden dowel to tap the back of the round until you have the rounds shoulder tight against the chamber shoulder, aim the muzzle up, and see if case will fall out. If no, then take a cleaning rod down the muzzle to tap the front of the bullet so the case does come out, and look to see were the round was binding. it on the case, then should be scrap marks on the case, while if the bullet, then should be signed of bullet embedding rifling at loading isntead.

Last check before I go too deep into writing a novel, gut a plastic mag and a metal mag, to get them down to their bodies alone. on the lower, push the mag release button all the way into the channel with back end of a pencil, then reach over to the other side to thread off the other side of the mag caught, and remove all three parts of the mag catch from the lower receiver. Now with B/C back in, and locked home, need to you insert each mag into the mag well, until the lips of the mag seat flush against the bottom of the carrier, then look into the mag catch slot on the non ejection side, and see how much of the mag catch slot for the catch, is above bottom of the catch slot itself. Ideally, should only be about 1/16" of an inch,

Meaning that when the mag is locked home in the mag well by the mag catch, its only low about 1/16" from the lips biding on the bottom of the mag. If mag is lock in place in the mag well lower than this, can cause all kinds of feed problems with the angle rate of the round out of the front of the mag, well too low for clean entry into chamber. hence if other uppers work fine, and its just this upper receiver the problem, could be that the center line for B/C channel was milled either too high, or too low in the receiver itself, and has the distance from mag catch in the lower, not in the correct distance to bottom of bolt isntead.

Note, when mag catch is reinstalled, end of the threaded section, should be flush with the face of the button.

Also, double check the front inside of the mag well, up in the upper receiver. On some uppers, the front part is not milled enough forward, which can cause the mag to not be able to be pushed all the way up cleanly in place, but instead the upper protruding lip blocking the mag from being able to be inserted all the way up.

Last one, check the feed ramps of the barrel extension, to make sure than are matching the upper receiver type as well (if both are standard, or one is a M4 extended ramp, with the other not.

P.s. When you state plastic verse metal mags, are we talking both USGI approved, or some knock off clones that may have feed problem in themselves.

Also, this is an Ar-15, where CLP is used to clean and lube the gun, not an M-14 or Grand, when grease was used to lube some of the steel on steel parts isntead. If you are using grease on any part of the gun, its a problem in itself.

Substituent CLP for where is states LSA, and will have you covered on how to clean and lube the rifle correctly.

Note, If stuck in a fox hole too long in country, and will give you something to yank-off to as well.

Win a FREE Membership!

Win a FREE Membership!