|

After a bit of a break I'm back on Thing 644933 I made myself an Excel spreadsheet so I can keep track of what I've printed and what parts get what color.

|

|

|

WELCOME to The Forums at Brownells.com - Sorry about your wallet.

Order of the Penquin |

|

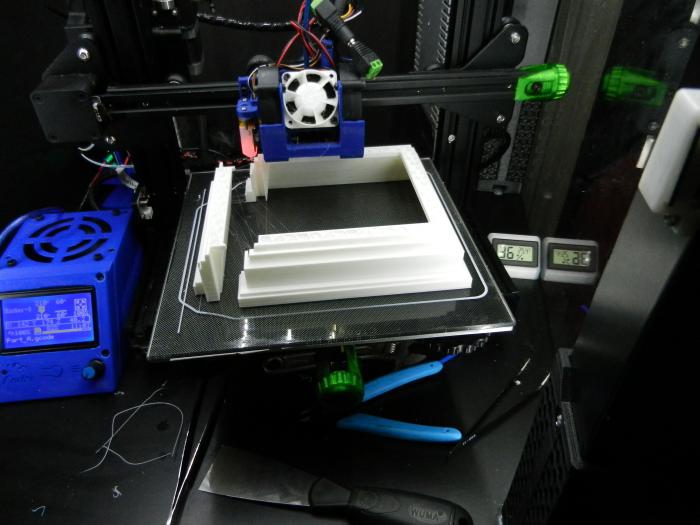

Printing post base trim pieces for the front porch. The wife didn't like what the contractor used originally (too plain & used a caulking on the joint that mildewed black) so I'm doing replacements. The pattern was found on thingiverse (https://www.thingiverse.com/thing/4004169), but was for a different post cover so it needed scaling up by about 7%, plus the original parts didn't match up well using my setup so I had to modify one part for a better slip fit.

|

|

|

|

|

Originally Posted By nikdfish:

Printing post base trim pieces for the front porch. The wife didn't like what the contractor used originally (too plain & used a caulking on the joint that mildewed black) so I'm doing replacements. The pattern was found on thingiverse (https://www.thingiverse.com/thing/4004169), but was for a different post cover so it needed scaling up by about 7%, plus the original parts didn't match up well using my setup so I had to modify one part for a better slip fit. http://www.skhowell.com/images/DSCN6432.jpg http://www.skhowell.com/images/DSCN6434.jpg http://www.skhowell.com/images/DSCN6435.jpg View Quote |

|

|

WELCOME to The Forums at Brownells.com - Sorry about your wallet.

Order of the Penquin |

|

I'd just hit it with some white spray paint personally.

|

|

|

|

|

To tell you the truth, no idea how well it will hold up. If it starts to discolor then paint would be the probable route. We'll wait & see...

|

|

|

|

|

PLA would not hold up, but I think ABS would do fine. I've used ABS stuff outside before. Not sure on PETG, but water bottles never go anywhere when left outside...

What pigments of the manufacturer of your filament would make a big difference on the color though. A shot of plastic outdoor white would probably be a great idea though. Cheap insurance. Could go all out and get the Hammer Finish from Rustoleum |

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

Originally Posted By Rat_Patrol:

PLA would not hold up, but I think ABS would do fine. I've used ABS stuff outside before. Not sure on PETG, but water bottles never go anywhere when left outside... What pigments of the manufacturer of your filament would make a big difference on the color though. A shot of plastic outdoor white would probably be a great idea though. Cheap insurance. Could go all out and get the Hammer Finish from Rustoleum View Quote |

|

|

WELCOME to The Forums at Brownells.com - Sorry about your wallet.

Order of the Penquin |

|

I wanted a quick print to verify the swapped out stepper driver fix, so I did this keyfob that I built from a BFL graphic a while back when playing with .SVG -> .stl via Tinkercad ....

Tinkercad files here: https://www.tinkercad.com/things/cAlDmqkL4Z3 |

|

|

|

|

Originally Posted By nikdfish:

I wanted a quick print to verify the swapped out stepper driver fix, so I did this keyfob that I built from a BFL graphic a while back when playing with .SVG -> .stl .... http://www.skhowell.com/images/DSCN6436.jpg View Quote

|

|

|

"You know how butt ugly people are said to have hit every branch on the way down the ugly tree.

Well, the dumbass tree done drilled you in the butt and laid eggs in ya." -RJinks |

|

"It's hard to hear a wallet screaming over the sound of a pecker cheering"

--WinstonSmith "If this is how the state treats its law-abiding citizens, it doesn't deserve to have any" --Solzhenitsyn |

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

WELCOME to The Forums at Brownells.com - Sorry about your wallet.

Feeling like a ham and mustard shake |

|

Originally Posted By RV8guy:

Finished up printing the parts for the model Toyota 22RE. Working on the transmission and transfer case right now. I'm about out of filament though. https://i.imgur.com/7XSsgDG.jpg?2 View Quote |

|

|

"You know how butt ugly people are said to have hit every branch on the way down the ugly tree.

Well, the dumbass tree done drilled you in the butt and laid eggs in ya." -RJinks |

|

WELCOME to The Forums at Brownells.com - Sorry about your wallet.

Feeling like a ham and mustard shake |

|

Got back to working on the 1/10 scale "MKUltra" truggy build I started a while back. When going to assemble some front suspension components, clearance on the pressed in bearings was just too tight. Way too much drama trying to get bearings to settle in to the depth needed for proper screw clearances.

I scrapped the existing printed components & did some clearance test prints with my currently loaded eSun PLA+ using a set of calibration clips (like puzzle pieces) at my current print temperature (see https://www.thingiverse.com/thing:2502677 ). I used used different filament diameter settings to tweak extrusion amounts until they printed in the "Goldilocks zone" where they would fit up cleanly with not too much or too little clearance. (back story: my extruder steps are correctly calibrated - if I tell it to extrude 100mm, it will push 100mm) I just needed to find the sweet spot for the current temp. (In Cura, filament diameter is in the printer settings area, which can be added to the profile sidebar via a marketplace plugin & then has to be manually set to visible for easy access).

With the new setting, the printed components allowed the nuts & bearings to be properly seated without any drama & could be recessed to the desired point just by tightening the screws a bit & then backing off. I'll probably have to repeat the process for a few more of the fit critical components on the rear suspension & drive train. The clips can be used as documentation of the settings used & also as touchstones for later prints using different materials that need to nest/mesh with components printed with the same settings as the clips. |

|

|

|

|

All it does is get line widths in the neighborhood so you dont have to do them all manually, not directly used for any extruded volume calculations. You could set filament dia to 100mm and it would print fine, as long as you set all the line widths appropriately. ETA Im smoking crack and was thinking nozzle dia. Beat up from flying all day

|

|

|

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

I designed a +4 mag extension for my S&W M&P 9.This is the 11th version of the design and it could still use a couple of tweeks. I just got my printer a couple of weeks ago and am still learning. Any way I posted it on Thingiverse.

M&P9 Mag Extension V11 |

|

|

|

|

"It's hard to hear a wallet screaming over the sound of a pecker cheering"

--WinstonSmith "If this is how the state treats its law-abiding citizens, it doesn't deserve to have any" --Solzhenitsyn |

|

I printed a couple of those whistles. They never worked right

|

|

|

"You know how butt ugly people are said to have hit every branch on the way down the ugly tree.

Well, the dumbass tree done drilled you in the butt and laid eggs in ya." -RJinks |

|

Originally Posted By rcav8r:

I printed a couple of those whistles. They never worked right View Quote The reason I ask, is cause maybe it built supports inside the whistle part. I've printed 4 of those Mayan/Aztec Death whistles using different filaments and each one has turned our great and sound great. I love the sound of them. Go out late at night and blow as hard as you can and it gets the coyotes riled up. |

|

|

|

|

Originally Posted By stonedv8: Did you use supports? If so did you make sure to set the slicer to only form supports for the structure touching bed? The reason I ask, is cause maybe it built supports inside the whistle part. I've printed 4 of those Mayan/Aztec Death whistles using different filaments and each one has turned our great and sound great. I love the sound of them. Go out late at night and blow as hard as you can and it gets the coyotes riled up. View Quote |

|

|

"You know how butt ugly people are said to have hit every branch on the way down the ugly tree.

Well, the dumbass tree done drilled you in the butt and laid eggs in ya." -RJinks |

|

|

|

|

|

Got my 13 year old son an Ender 3 Pro for Christmas. We have it all set up and the first print (test dog) is happening right now.

We are both complete n00bs to this; if nothing else we are making memories |

|

|

|

|

Originally Posted By Pickle:

Got my 13 year old son an Ender 3 Pro for Christmas. We have it all set up and the first print (test dog) is happening right now. We are both complete n00bs to this; if nothing else we are making memories View Quote And when your not, check in here. We can collectively: A: Confuse you more B: Figure out the issue |

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

Originally Posted By Rat_Patrol:

You will be fine. And when your not, check in here. We can collectively: A: Confuse you more B: Figure out the issue View Quote View All Quotes View All Quotes Originally Posted By Rat_Patrol:

Originally Posted By Pickle:

Got my 13 year old son an Ender 3 Pro for Christmas. We have it all set up and the first print (test dog) is happening right now. We are both complete n00bs to this; if nothing else we are making memories And when your not, check in here. We can collectively: A: Confuse you more B: Figure out the issue |

|

|

|

|

Dog failed part way through, about 4 hours in - came unstuck from the base and started moving all over the bed getting dragged around. Looked really good up to that point, then it just looked like someone started spraying squeeze cheese all over it.

Today we are trying an Archimedes spiral since that is what his science fair project is about this year so a model of one may come in handy. |

|

|

|

|

Originally Posted By Pickle:

Dog failed part way through, about 4 hours in - came unstuck from the base and started moving all over the bed getting dragged around. Looked really good up to that point, then it just looked like someone started spraying squeeze cheese all over it. Today we are trying an Archimedes spiral since that is what his science fair project is about this year so a model of one may come in handy. View Quote #1 Check and double check your bed is level. Even if the 4 corners are level, you can have a droop in the middle where the majority of the prints sit. If you are getting some leveling issues in the middle, sometimes a small piece of foil placed in that spot is enough to get it to proper levels. If this is indeed the case, go to Home Depot or Lowes and get a 1/8" piece of glass cut for around $3 and replace the magnetic bed. Mine had the same issue with the offcenter in the middle and the glass solved ALL of my problems. #2 Clean the bed with rubbing alcohol in between prints, gets oil, grease and dust off of the bed and dries quickly. #3 With continued bed adhesion problems, sometimes a small spray of hairspray or a few swipes of stick glues will work wonders. Gives a little bit of texture for adhesion. If you watch alot of 3D print videos and the show the print area, 9 times out of 10 you will see a can of Aquanet Hairspray around the area. Bed Adhesion and leveling are probably the most common 3D printer problems and usually some of the easiest things to fix. And they both go hand in hand. |

|

|

|

|

Originally Posted By stonedv8:

This may reach you too late for the start of the spiral, but since the dog came off of the bed. A few tips. #1 Check and double check your bed is level. Even if the 4 corners are level, you can have a droop in the middle where the majority of the prints sit. If you are getting some leveling issues in the middle, sometimes a small piece of foil placed in that spot is enough to get it to proper levels. If this is indeed the case, go to Home Depot or Lowes and get a 1/8" piece of glass cut for around $3 and replace the magnetic bed. Mine had the same issue with the offcenter in the middle and the glass solved ALL of my problems. #2 Clean the bed with rubbing alcohol in between prints, gets oil, grease and dust off of the bed and dries quickly. #3 With continued bed adhesion problems, sometimes a small spray of hairspray or a few swipes of stick glues will work wonders. Gives a little bit of texture for adhesion. If you watch alot of 3D print videos and the show the print area, 9 times out of 10 you will see a can of Aquanet Hairspray around the area. Bed Adhesion and leveling are probably the most common 3D printer problems and usually some of the easiest things to fix. And they both go hand in hand. View Quote View All Quotes View All Quotes Originally Posted By stonedv8:

Originally Posted By Pickle:

Dog failed part way through, about 4 hours in - came unstuck from the base and started moving all over the bed getting dragged around. Looked really good up to that point, then it just looked like someone started spraying squeeze cheese all over it. Today we are trying an Archimedes spiral since that is what his science fair project is about this year so a model of one may come in handy. #1 Check and double check your bed is level. Even if the 4 corners are level, you can have a droop in the middle where the majority of the prints sit. If you are getting some leveling issues in the middle, sometimes a small piece of foil placed in that spot is enough to get it to proper levels. If this is indeed the case, go to Home Depot or Lowes and get a 1/8" piece of glass cut for around $3 and replace the magnetic bed. Mine had the same issue with the offcenter in the middle and the glass solved ALL of my problems. #2 Clean the bed with rubbing alcohol in between prints, gets oil, grease and dust off of the bed and dries quickly. #3 With continued bed adhesion problems, sometimes a small spray of hairspray or a few swipes of stick glues will work wonders. Gives a little bit of texture for adhesion. If you watch alot of 3D print videos and the show the print area, 9 times out of 10 you will see a can of Aquanet Hairspray around the area. Bed Adhesion and leveling are probably the most common 3D printer problems and usually some of the easiest things to fix. And they both go hand in hand. We will re-check and re-check the bed leveling; thanks again for the tips. |

|

|

|

|

I've never had great luck with Aquanet on my glass bed (and I've tried several different 'flavors'). I generally just use a glue stick.

Playing around with the first layer height can result in better adhesion. On my glass bed, I usually use a lower height for more 'squish'. I also use about 1mm of Z hop on most of my prints, to prevent accidental collisions. |

|

|

|

|

|

|

What's it called when you have a pen, for example, linked to your writing pen so you get an exact replica copy?

Can 3D printers be modded to do 3D exterior scans of say a bust? Couldn't you replace the nozzle with a laser and get a 3D exterior rendering? |

|

|

|

|

Its not quite that easy, but you can pretty much do those things.

They make 3d scanners, and even sw to scan with a normal cam. Not played with 2d stuff, but surely sw out that will convert that pretty painlessly also. |

|

|

|

|

No photos, but just another instance of a 3d printer being handy. Got one of the Holosun 507's in today, and the screws for my slide didn't snug it down enough. Used a model I already had for a RMR slide plate, and printed a 0.5mm thick version. It's like a perfect custom shim. 20 minutes from start to finish.

|

|

|

Literal vampire pot bellied goblins.

|

|

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

Originally Posted By hoosier122:

What's it called when you have a pen, for example, linked to your writing pen so you get an exact replica copy? Can 3D printers be modded to do 3D exterior scans of say a bust? Couldn't you replace the nozzle with a laser and get a 3D exterior rendering? View Quote In my experience, 3d scanners aren’t quite accurate enough yet for that. You have to post process the resultant file for good results. |

|

|

"It's hard to hear a wallet screaming over the sound of a pecker cheering"

--WinstonSmith "If this is how the state treats its law-abiding citizens, it doesn't deserve to have any" --Solzhenitsyn |

|

|

|

|

|

Originally Posted By Turbo_Kill3r:

3 mag holder I found on Thingiverse. Just attached some magnets on the back and stuck it to the back of my cabinet door. Works great. https://i.imgur.com/cP8JVws.jpg?1 View Quote |

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

Originally Posted By Rat_Patrol:

I like that. Link? View Quote View All Quotes View All Quotes Originally Posted By Rat_Patrol:

Originally Posted By Turbo_Kill3r:

3 mag holder I found on Thingiverse. Just attached some magnets on the back and stuck it to the back of my cabinet door. Works great. https://i.imgur.com/cP8JVws.jpg?1 I had a couple of failures right at the end which was disappointing since it was not a fast print. I just used cheap PLA with 210 on the hotend and the bed at 60. I have a Ender 3 Pro. |

|

|

|

|

|

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

|

"It's hard to hear a wallet screaming over the sound of a pecker cheering"

--WinstonSmith "If this is how the state treats its law-abiding citizens, it doesn't deserve to have any" --Solzhenitsyn |

|

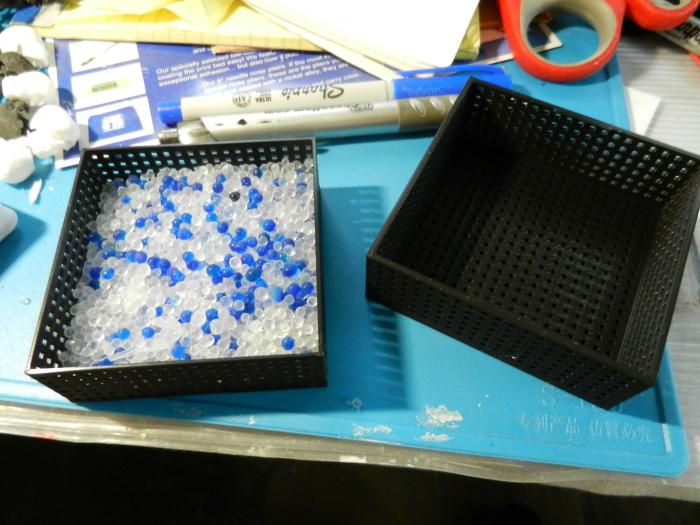

Added another 5 gallon bucket w/gamma seal lid to the filament storage stash and that brought up adding one or more desiccant boxes. I have played with a few different styles and finally got around to making one of my own design. I 4x4x1 and 3x3x1 versions. There are perforations on all 6 sides & they align on the sides when closed. Tabs snap into reliefs to hold the box closed. The perforations are about 1.5 - 1.7mm, so they should work OK with the 2-5mm beads I buy. I have another 5 lb. of beads coming in (can't keep from bumping up an order when a 25% increase in cost more than doubles the product amount). These are all uncolored, I'll mix with some of the existing blue beads when I replace some of the old containers I don't like.

This is the 4x4x1 version

printed in eSun PLA+ After printing & fit testing, I put it (closed) in the dehydrator set at 70°C for a half hour to see what would happen. It was somewhat pliable when removed, but not really distorted other than the top surface sagging a bit. The slide fit helps. I had no trouble separating top & bottom and after a quick re-heat I set the top down upside down on a flat surface & flattened the sag. I think it would do OK if filled with silica beads. I don't want to remove/replace silica for recharging. I just need to avoid over-filling so the amount will be OK once the annealing shrink occurs. All the perforations made Tinkercad a bit wonky  , with a tendancy to lose the session connection, but I finally got things done & safely saved. , with a tendancy to lose the session connection, but I finally got things done & safely saved.

This is the 4x4x1 version : https://www.tinkercad.com/things/6ahNs0Nl9S6 This is the 3x3x1 version: https://www.tinkercad.com/things/0dQooKQkrfc Also available on Thingiverse: https://www.thingiverse.com/thing:4145841 Both have been printed & tested. This is the 3x3x1 with silica beads added, a mix of new white beads & blue indicator beads from a replaced container:

... and after assembly

|

|

|

|

Another type of SMD component holder, for my left side resistors. I don't buy in full spools for prototyping, so they work great for cut tape, some of them having 1000 pieces and I leave them in the bag they come in and just hang them over the edge. The printed holder actually has a radius edge to relieve strain on the tape. Again, specifically to contain the cover tape and give a place for a barcode for component tracking. Now when I start a PCB (serial numbered), I scan all components used with my wireless scanner. ETA: Just dropped them on Thingiverse. https://www.thingiverse.com/thing:4144463 |

|

|

Strong men create good times. Good times breed weak men. Weak men create hard times. Hard times breed strong men.

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.