|

Yeah, Reed Knight had a better fence.

The Canadians seemed to like their guns pretty well. |

|

|

|

|

|

Quoted:

The world is literally "filled" with much better epoxies than JB weld, not that I am recommending gluing the extension into the upper. Side note, did Armalite win the SASS contract?

Well if it involves production grade barrels chambered in 7.62 shooting mil spec ammo then I would not be at all surprised the differences would be hard to discern. You do realize some shoot high grade barrels and can assemble very high quality ammo, right? I guess we all have our opinions.

I would agree that spending much time breaking in a production grade .308 Win barrel shooting M118LR is a waste. On the other hand if you want to run 140gr 6.5mm VLDs at 3300fps through an expensive handlapped barrel then an afternoon of shoot 5 and clean for the first 25 rounds is going to pay dividends. Barrel breakin is a pretty broad subject to simply say "voodoo" or at least that is my opinion. View Quote View All Quotes View All Quotes Quoted:

Quoted:

The Super SASS was, AR-10T...we tested for .mil and export. Facing and bedding did not make a statistically significant difference. However, if I was going to glue a barrel into a receiver, I would use JB weld. The world is literally "filled" with much better epoxies than JB weld, not that I am recommending gluing the extension into the upper. Side note, did Armalite win the SASS contract?

Quoted:

The other issue revolves around the test method itself...don't get me started on that... Well if it involves production grade barrels chambered in 7.62 shooting mil spec ammo then I would not be at all surprised the differences would be hard to discern. You do realize some shoot high grade barrels and can assemble very high quality ammo, right? Quoted:

FWIW, I think barrel break in is voodoo. I guess we all have our opinions.

I would agree that spending much time breaking in a production grade .308 Win barrel shooting M118LR is a waste. On the other hand if you want to run 140gr 6.5mm VLDs at 3300fps through an expensive handlapped barrel then an afternoon of shoot 5 and clean for the first 25 rounds is going to pay dividends. Barrel breakin is a pretty broad subject to simply say "voodoo" or at least that is my opinion. Opinions are like assh**** ...so what exactly are your bona fides. |

|

|

|

|

|

|

|

|

|

Quoted:

Opinions are like assh**** ...so what exactly are your bona fides. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

The Super SASS was, AR-10T...we tested for .mil and export. Facing and bedding did not make a statistically significant difference. However, if I was going to glue a barrel into a receiver, I would use JB weld. The world is literally "filled" with much better epoxies than JB weld, not that I am recommending gluing the extension into the upper. Side note, did Armalite win the SASS contract?

Quoted:

The other issue revolves around the test method itself...don't get me started on that... Well if it involves production grade barrels chambered in 7.62 shooting mil spec ammo then I would not be at all surprised the differences would be hard to discern. You do realize some shoot high grade barrels and can assemble very high quality ammo, right? Quoted:

FWIW, I think barrel break in is voodoo. I guess we all have our opinions.

I would agree that spending much time breaking in a production grade .308 Win barrel shooting M118LR is a waste. On the other hand if you want to run 140gr 6.5mm VLDs at 3300fps through an expensive handlapped barrel then an afternoon of shoot 5 and clean for the first 25 rounds is going to pay dividends. Barrel breakin is a pretty broad subject to simply say "voodoo" or at least that is my opinion. Opinions are like assh**** ...so what exactly are your bona fides. You have Google and my user name.

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. |

|

|

|

|

|

Quoted:

You have Google and my user name.

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

The world is literally "filled" with much better epoxies than JB weld, not that I am recommending gluing the extension into the upper. Side note, did Armalite win the SASS contract?

Quoted:

The other issue revolves around the test method itself...don't get me started on that... Well if it involves production grade barrels chambered in 7.62 shooting mil spec ammo then I would not be at all surprised the differences would be hard to discern. You do realize some shoot high grade barrels and can assemble very high quality ammo, right? Quoted:

FWIW, I think barrel break in is voodoo. I guess we all have our opinions.

I would agree that spending much time breaking in a production grade .308 Win barrel shooting M118LR is a waste. On the other hand if you want to run 140gr 6.5mm VLDs at 3300fps through an expensive handlapped barrel then an afternoon of shoot 5 and clean for the first 25 rounds is going to pay dividends. Barrel breakin is a pretty broad subject to simply say "voodoo" or at least that is my opinion. Opinions are like assh**** ...so what exactly are your bona fides. You have Google and my user name.

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. There's a lot of John Burns been at a lot of different places... Ought to do what he says, there's a lot of material to sift through. |

|

|

|

Quoted:

Quoted:

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. I guess you like to hunt Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. |

|

|

|

Quoted:

Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. I guess you like to hunt Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. WWII bomber crews believed in magic to give them an edge...if it worked for them it should work for you |

|

|

|

Quoted:

WWII bomber crews believed in magic to give them an edge...if it worked for them it should work for you View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Quoted:

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. I guess you like to hunt Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. WWII bomber crews believed in magic to give them an edge...if it worked for them it should work for you LOL. I don't believe in magic, I just understand how the upper/ extension joint moves and how a proper breakin process expedites accuracy.

On the flip side you have a bunch of experience with production grade .308 Win/ 7.62 NATO barrels shooting mil spec ammo. Congratulations? Hint: You have been led to water, but will you drink??????? |

|

|

|

Quoted:

Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. I guess you like to hunt Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. Will you share, your opinions, on upper to extension fitting/bedding? I would like to hear about your method of barrel break in also. If it's info for your customers only, I understand. Thanks |

|

|

|

Quoted:

Will you share, your opinions, on upper to extension fitting/bedding? I would like to hear about your method of barrel break in also. If it's info for your customers only, I understand. Thanks View Quote The best way for a guy to stabilize the joint on an existing extension/ upper is to paint on an interference fit. I have had good results with Cerakote but I suspect a good high temp engine or barbecue paint would work as well. The best results come from painting just a 1/2" band at the lug end of the extension. This ensures positive capture of the extension at the lug end while the barrel nut grabs at the flange end. Heating the upper will allow an .002 interference to fit slide right in without scraping off the Cerakote. Heating the upper will allow easy disassembly of said assembly. I shoot at least 5 shots between cleans as it goes much faster than one shot between cleans. KG products work the best, both the carbon remover and the copper remover. Bronze brush to scrub carbon and nylon to remove copper. 50 strokes with KG1 on bronze brush for carbon. 200 strokes with KG12 on nylon will get all the copper from the first rounds of a magnum rifle shooting long bullets, takes about 5 minutes. .223s/ ..308s/ 6.5 CMs and such don't copper foul much in good barrels but keeping the copper out of the port goes a long way in keeping the port from lifting. If an AR barrel gets a build up of copper at the front edge of the port it can actually cause the edge to lift from the bore surface. Such a barrel will always throw flyers and never really shoot great. |

|

|

|

Quoted:

LOL. I don't believe in magic, I just understand how the upper/ extension joint moves and how a proper breakin process expedites accuracy.

On the flip side you have a bunch of experience with production grade .308 Win/ 7.62 NATO barrels shooting mil spec ammo. Congratulations? Hint: You have been led to water, but will you drink??????? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Quoted:

Quoted:

Throw in Long Range Hunting to narrow the field, lots of John Burns runnin around. I guess you like to hunt Yes I do. I am also not a Civil War Hero, a real estate consultant, journalist, or any other cool shit. I have built long range precision hunting rifles for decades. I do have an opinion on barrel breakin and stabilizing the upper/ extension joint in the AR/Stoner design. Others might have different opinions. That is what make horse races. WWII bomber crews believed in magic to give them an edge...if it worked for them it should work for you LOL. I don't believe in magic, I just understand how the upper/ extension joint moves and how a proper breakin process expedites accuracy.

On the flip side you have a bunch of experience with production grade .308 Win/ 7.62 NATO barrels shooting mil spec ammo. Congratulations? Hint: You have been led to water, but will you drink??????? |

|

|

|

Quoted:

The best way for a guy to stabilize the joint on an existing extension/ upper is to paint on an interference fit. I have had good results with Cerakote but I suspect a good high temp engine or barbecue paint would work as well. The best results come from painting just a 1/2" band at the lug end of the extension. This ensures positive capture of the extension at the lug end while the barrel nut grabs at the flange end. Heating the upper will allow an .002 interference to fit slide right in without scraping off the Cerakote. Heating the upper will allow easy disassembly of said assembly. I shoot at least 5 shots between cleans as it goes much faster than one shot between cleans. KG products work the best, both the carbon remover and the copper remover. Bronze brush to scrub carbon and nylon to remove copper. 50 strokes with KG1 on bronze brush for carbon. 200 strokes with KG12 on nylon will get all the copper from the first rounds of a magnum rifle shooting long bullets, takes about 5 minutes. .223s/ ..308s/ 6.5 CMs and such don't copper foul much in good barrels but keeping the copper out of the port goes a long way in keeping the port from lifting. If an AR barrel gets a build up of copper at the front edge of the port it can actually cause the edge to lift from the bore surface. Such a barrel will always throw flyers and never really shoot great. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Will you share, your opinions, on upper to extension fitting/bedding? I would like to hear about your method of barrel break in also. If it's info for your customers only, I understand. Thanks The best way for a guy to stabilize the joint on an existing extension/ upper is to paint on an interference fit. I have had good results with Cerakote but I suspect a good high temp engine or barbecue paint would work as well. The best results come from painting just a 1/2" band at the lug end of the extension. This ensures positive capture of the extension at the lug end while the barrel nut grabs at the flange end. Heating the upper will allow an .002 interference to fit slide right in without scraping off the Cerakote. Heating the upper will allow easy disassembly of said assembly. I shoot at least 5 shots between cleans as it goes much faster than one shot between cleans. KG products work the best, both the carbon remover and the copper remover. Bronze brush to scrub carbon and nylon to remove copper. 50 strokes with KG1 on bronze brush for carbon. 200 strokes with KG12 on nylon will get all the copper from the first rounds of a magnum rifle shooting long bullets, takes about 5 minutes. .223s/ ..308s/ 6.5 CMs and such don't copper foul much in good barrels but keeping the copper out of the port goes a long way in keeping the port from lifting. If an AR barrel gets a build up of copper at the front edge of the port it can actually cause the edge to lift from the bore surface. Such a barrel will always throw flyers and never really shoot great. Thank you very much sir, that is informative. What kinda temp do you recomend on the upper ? |

|

|

|

Quoted:

That was ArmaLite's position when I worked there. View Quote View All Quotes View All Quotes Quoted:

Quoted:

FWIW, I think barrel break in is voodoo. That was ArmaLite's position when I worked there. Armalite advertised their barrels as double lapped. Do you know the reasoning behind that? I believe if there is a benefit to lapping the front of the receiver and tightening the tolerance between the extension and the receiver socket, it is an even, more consistent vibration pattern. |

|

|

|

My method is similar to Mr. Burns.

Specifically: I VERY softly and carfully cross hatch the exterior of the receiver extension. This allows for a bit of good CeraKote adhesion. I tape off one section of the extension near the barrel seat and a small band near the locking lugs, leaving a fairly wide center band that I will paint. Depending on how loose the extension is creates the thickness I will apply in CeraKote. I try to go just a wee bit thick....but only a WEE bit. This is done by guesswork more than anything. I set up the barrel so that I can easily paint around it as much as possible. After I paint it, I let the CeraKote gas out a for about a half hour an then put it in the oven at 175 for another half hour before slowing bumping it up to cure temperature. This is about the time that I de-tape. I usually work about 30 to 50 degrees below official cure temp and just cure longer when I do sensitive stuff like barrels and receivers. While all of that is going on I take a standard ol' prescription pill bottle and cut the bottom and the top flange off of it. I cut out a section of the length leaving me an "adjustable mandril. Using think two sided tap, I glue in some more 800 grit automotive paper. When the C-kote is cured, I test fit the barrel onto the upper making sure that I am careful not to bind it. If you stick it...you will need a heat gun to get it out. I wet sand the extension until it barely slip fits. Then I wash everything in the sink once it fits, carefully dry it and then go to work on assembly. This time, I am going to add a thin coat of blue loc-tight to take up the space in the slip fit, just for fun. |

|

|

|

Quoted:

View Quote View All Quotes View All Quotes Quoted:

Wait...a few pages back you referred to barrel bedding procedures as "spurious." I had to look that word up and learned it means fake. Quoted:

Quoted:

Quoted:

As I've stated before, in this thread and elsewhere, once the barrel nut is tightened (even just past hand tight), the barrel isn't going anywhere. It seems people are getting better accuracy using these techniques. Can you explain why that may be? It's spurious. But now that the precision AR builder who uses barrel/receiver bedding techniques has called your bluff you want to call his guns race cars? So, I guess i am really confused now. Do you, or do your not, think there is any possible benefit to using bedding techniques, as discussed in this thread, to increase accuracy? |

|

|

|

Quoted:

Wait...a few pages back you referred to barrel bedding procedures as "spurious." I had to look that word up and learned it means fake. But now that the precision AR builder who uses barrel/receiver bedding techniques has called your bluff you want to call his guns race cars? So, I guess i am really confused now. Do you, or do your not, think there is any possible benefit to using bedding techniques, as discussed in this thread, to increase accuracy? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Wait...a few pages back you referred to barrel bedding procedures as "spurious." I had to look that word up and learned it means fake. Quoted:

Quoted:

Quoted:

As I've stated before, in this thread and elsewhere, once the barrel nut is tightened (even just past hand tight), the barrel isn't going anywhere. It seems people are getting better accuracy using these techniques. Can you explain why that may be? It's spurious. But now that the precision AR builder who uses barrel/receiver bedding techniques has called your bluff you want to call his guns race cars? So, I guess i am really confused now. Do you, or do your not, think there is any possible benefit to using bedding techniques, as discussed in this thread, to increase accuracy? My reply was in regards to production rifles. I have never seen evidence that barrel break in or bedding increases accuracy on an AR-10. I would like to see someone conduct a DOE to see if there is statistically significant difference over a rifle built to print. What John is implying is a bunch of little things can add up. For a person that can out shoot a rifle it may add up. Then again it may just be a boost in confidence. We would agree that the most important component of the accuracy equation is the person shooting the rifle. For 99.9% of shooters a rile built to print with match ammo will do the job. |

|

|

|

Quoted:

Wait...a few pages back you referred to barrel bedding procedures as "spurious." I had to look that word up and learned it means fake. But now that the precision AR builder who uses barrel/receiver bedding techniques has called your bluff you want to call his guns race cars? So, I guess i am really confused now. Do you, or do your not, think there is any possible benefit to using bedding techniques, as discussed in this thread, to increase accuracy? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Wait...a few pages back you referred to barrel bedding procedures as "spurious." I had to look that word up and learned it means fake. Quoted:

Quoted:

Quoted:

As I've stated before, in this thread and elsewhere, once the barrel nut is tightened (even just past hand tight), the barrel isn't going anywhere. It seems people are getting better accuracy using these techniques. Can you explain why that may be? It's spurious. But now that the precision AR builder who uses barrel/receiver bedding techniques has called your bluff you want to call his guns race cars? So, I guess i am really confused now. Do you, or do your not, think there is any possible benefit to using bedding techniques, as discussed in this thread, to increase accuracy? Is there proof that it does? Here is an example- Many gunsmiths swear that you must true the bolt face on a 700 for max accuracy. Lets think about that bolt face with a round in the chamber. The round is being pressed forward by the ejector, so it isn't sitting on the bolt face. Further, it isn't squarely being pushed as the ejector is on one side and the extractor on the other which is pretty much all that is holding the round on the bolt at that point depending on your headspace. Yet...that surface...that the round isn't even touching or at least, isn't resting squarely against...is "critical" to accuracy if you listed to a lot of people who make money trueing that surface. Now lets think about the amount of clearance on each side the the chamber combined with the above. Is the round now square to the bore? Nope... Yet all of those things...bolt face, chamber, throat and so on are critical to accuracy... I doubt the benifit of bedding the extension. I don't doubt that you could unitize the parts with an adhesive or similar and maybe see some benifit...maybe. There would have to be some real testing to prove it thought. |

|

|

|

Mr. Burns' procedure actually makes sense for building a precision rifle. He gets the closest thing to a "perfect fit" between the barrel extension and the upper using a simple, repeatable process. Whether or not he can show any benefit from his process over not using it, it is not going to hurt anything. And by his wording, I get the impression that he's using top quality barrels and uppers as well, which makes a difference. Heating an upper with a 700ºF heat gun for just a few seconds should cause enough expansion to let an "oversized" (with Cerrocoat) barrel extension slip in fairly easily.

As to the "race car versus daily commuter" point, it is valid. I would want a Formula 1 car to have all the potential speed and control enhancements, whether or not the car had shown issues before. But a Formula 1 car is built with hand-made parts, assembled by a highly trained team with the best tools and measurement devices, and tuned by someone the car's owners pay way too much money to because of his level of expertise. A Ford Focus is built to have the maximum amount of safety while still being mobile, and to remain on the road in relative safety for about 100,000 miles. Just a few minutes search with Google will turn up a LOT of options for making a Focus go faster, handle better, but all of that generally doesn't change into something other than a Ford Focus. So when I look at the discussions here, I see people who seem to be on Formula 1 teams talking about their practices, and I see people with Fords acting as if changing out their shocks and putting on expensive alloy wheels will make their Fords into Formula 1 cars. Maybe I'm misreading, but that's how it's coming across. And no matter what you do to a Focus, it's going to be a Focus - even if it has really cool wheels, an exhaust that sounds like a chainsaw and fancy ground effects. In a competition gun that's made from competition grade parts and built by someone who knows the craft well, there are a lot of "extra steps" that may or may not be worth the effort, but that's part of that craft. The impression I get here is that a bunch of folks think they'll get their $800 ARs shooting .0001" groups just by throwing some Loctite on their barrel extensions and calling it good, and another bunch is buying receiver lapping tools and fairly expensive barrels, but they still don't have the basic understanding of how a "normal" AR goes together, so even with good parts and good tools, they aren't going to build a particularly accurate rifle. A stock AR15 or AR10 that is properly built and is without serious production and parts flaws should shoot to the potential of the ammunition you use in it if YOU are up to it. You'll probably get more "accuracy improvement" by handloading for that gun, and for learning and practicing good marksmanship skills, than from tearing it apart and doing lots of competition-oriented stuff to it. |

|

|

|

Quoted:

Mr. Burns' procedure actually makes sense for building a precision rifle. He gets the closest thing to a "perfect fit" between the barrel extension and the upper using a simple, repeatable process. Whether or not he can show any benefit from his process over not using it, it is not going to hurt anything. And by his wording, I get the impression that he's using top quality barrels and uppers as well, which makes a difference. Heating an upper with a 700ºF heat gun for just a few seconds should cause enough expansion to let an "oversized" (with Cerrocoat) barrel extension slip in fairly easily. As to the "race car versus daily commuter" point, it is valid. I would want a Formula 1 car to have all the potential speed and control enhancements, whether or not the car had shown issues before. But a Formula 1 car is built with hand-made parts, assembled by a highly trained team with the best tools and measurement devices, and tuned by someone the car's owners pay way too much money to because of his level of expertise. A Ford Focus is built to have the maximum amount of safety while still being mobile, and to remain on the road in relative safety for about 100,000 miles. Just a few minutes search with Google will turn up a LOT of options for making a Focus go faster, handle better, but all of that generally doesn't change into something other than a Ford Focus. So when I look at the discussions here, I see people who seem to be on Formula 1 teams talking about their practices, and I see people with Fords acting as if changing out their shocks and putting on expensive alloy wheels will make their Fords into Formula 1 cars. Maybe I'm misreading, but that's how it's coming across. And no matter what you do to a Focus, it's going to be a Focus - even if it has really cool wheels, an exhaust that sounds like a chainsaw and fancy ground effects. In a competition gun that's made from competition grade parts and built by someone who knows the craft well, there are a lot of "extra steps" that may or may not be worth the effort, but that's part of that craft. The impression I get here is that a bunch of folks think they'll get their $800 ARs shooting .0001" groups just by throwing some Loctite on their barrel extensions and calling it good, and another bunch is buying receiver lapping tools and fairly expensive barrels, but they still don't have the basic understanding of how a "normal" AR goes together, so even with good parts and good tools, they aren't going to build a particularly accurate rifle. A stock AR15 or AR10 that is properly built and is without serious production and parts flaws should shoot to the potential of the ammunition you use in it if YOU are up to it. You'll probably get more "accuracy improvement" by handloading for that gun, and for learning and practicing good marksmanship skills, than from tearing it apart and doing lots of competition-oriented stuff to it. View Quote And when I get finished with this build, I will post pics of groups. |

|

|

|

The Ford to Formula 1 analogy is pretty good. I agree that the quality of the parts is more important than the assembly technique. But the assembly technique can be important too, and perhaps is more relevant with lower quality parts

|

|

|

|

I have been following this thread without saying anything (bet some are glad about that)

The question I have is, why wouldn't you? Truing the receiver, bedding the barrel, why wouldn't you? Blue loctite, gel loctite, Cerakote, Stainless shim material, barbecue paint. I have twice as much money in each one of my AR's that I could put in a bolt gun that arguably would be more accurate. But maybe not, mine shoot really well and I have done all this stuff. Why would you not true the receiver, bed the barrel, shim the extension for the exact torque you want if the barrel nut required it. Shorten the ejector spring, proper bolt head space, tighten the lower/upper fit, bevel the ejector, the whole 9 yards. Accuracy, bolt lug to extension alignment, barrel to upper bore alignment. Why with the money we put into these things would you not "blueprint" the machine. Capabilities of the shooter, sure. Capabilities of the hand loader, you bet. Not doing everything possible in your build to ensure the most accuracy and best operation, why not. Go buy a production gun? Sure they ran and shoot fine. Are they at the level they could be? You decide... |

|

|

|

Quoted:

Go buy a production gun? Sure they ran and shoot fine. Are they at the level they could be? You decide... View Quote This. If you're going to supreme precision, is good practice to use the techniques that are tried and true. Not everything has been scientifically tested in a lab, with numerous controls, variables, blah fucking blah. Not everyone has the time or resources to do this. Then those that do, most won't care enough. So, here's how i like to look at it. Lots of techniques are used by different champion shooters. Some use the same, some use voodoo, some use witch craft, whatever. I don't by into pseudo science stuff. But, bedding the barrel, by whatever methods you choose, makes things tighter. More snug. Which transmits into more consistent precision from your rig. Some techniques are better than others, some are bogus. I personally think the chemical adhesives are better than shims. I've always looked at shims as bandaids. I don't like them for anything. That's just a personal thing. Just bedding is not going to fix everything. Bedding, plus proper torque, proper alignment to the thousandths, all these add up to a supreme precise rig. The bedding is just one part of the equation. If you're going for a duty driven rifle, then none if that matters because you're not going to be shooting flies at 600yd with a duty rifle. Armalite makes superb duty rifles. They can be made better. QCMGR, can you shed any light on whether or not the SASS rifles were bedded or not? I thought i remember seeing something years ago about them being bedded. Could've been a one off, custom shop deal. There have been rather accurate rifles that are not bedded, and don't use any other "enhancing" techniques. However, that rifle has a limit that can be reached. The idea behind these precision rigs is to make them more precise than the shooter is capable of. Lots of people can shoot very well with basic setups, but that's only after serious range time with that specific rifle. It all depends on where you want to plateau. |

|

|

|

I agree with Yama_Raja's post regarding "Why Not?"

One thing I have learned from reading this thread is that some people refuse to believe something without seeing it spelled out using the Scientific Method. On the other hand I have learned some valuable information from John Burns. So, I'm glad I was here. Thank you, sir. |

|

|

|

Just to play devil's advocate...

The Larue Tactical OBR and PredatOBR are considered some of the most accurate factory semi auto rifles out there. Neither model has a bedded barrel and the PredatOBR even features a "quick" change disassembly/barrel swap capability. |

|

|

|

Quoted:

Just to play devil's advocate... The Larue Tactical OBR and PredatOBR are considered some of the most accurate factory semi auto rifles out there. Neither model has a bedded barrel and the PredatOBR even features a "quick" change disassembly/barrel swap capability. View Quote I myself, would not consider them to be run of the mill factory rifles. |

|

|

|

Quoted:

I myself, would not consider them to be run of the mill factory rifles. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Just to play devil's advocate... The Larue Tactical OBR and PredatOBR are considered some of the most accurate factory semi auto rifles out there. Neither model has a bedded barrel and the PredatOBR even features a "quick" change disassembly/barrel swap capability. I myself, would not consider them to be run of the mill factory rifles. A Bugatti Veyron is a production car. The McLaren F1 is as well, which runs on MSDOS by the way. But so is the Geo Metro, Ford Probe, etc. Like QCMGR has mentioned, if the rifle is blueprinted, critically machined, every part strictly controlled, as in the Larue gear, bugatti, ferrari, etc., you eliminate the need for these "enhancing" techniques. Basically you can bring out real consistency from PTAC gear, radical firearms stuff, and other bargain bin rifles if stripped down, and gone over with these methods. A larue or KAC will not benefit from these things because they are already there in terms of critical machining and matching of parts. |

|

|

|

Quoted: A Bugatti Veyron is a production car. The McLaren F1 is as well, which runs on MSDOS by the way. But so is the Geo Metro, Ford Probe, etc. Like QCMGR has mentioned, if the rifle is blueprinted, critically machined, every part strictly controlled, as in the Larue gear, bugatti, ferrari, etc., you eliminate the need for these "enhancing" techniques. Basically you can bring out real consistency from PTAC gear, radical firearms stuff, and other bargain bin rifles if stripped down, and gone over with these methods. A larue or KAC will not benefit from these things because they are already there in terms of critical machining and matching of parts. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: Just to play devil's advocate... The Larue Tactical OBR and PredatOBR are considered some of the most accurate factory semi auto rifles out there. Neither model has a bedded barrel and the PredatOBR even features a "quick" change disassembly/barrel swap capability. I myself, would not consider them to be run of the mill factory rifles. A Bugatti Veyron is a production car. The McLaren F1 is as well, which runs on MSDOS by the way. But so is the Geo Metro, Ford Probe, etc. Like QCMGR has mentioned, if the rifle is blueprinted, critically machined, every part strictly controlled, as in the Larue gear, bugatti, ferrari, etc., you eliminate the need for these "enhancing" techniques. Basically you can bring out real consistency from PTAC gear, radical firearms stuff, and other bargain bin rifles if stripped down, and gone over with these methods. A larue or KAC will not benefit from these things because they are already there in terms of critical machining and matching of parts. I would love to see a set of tests done with some high end ( Krieger etc) barrels and different barrel extensions, bedding methods, uppers and lapping tools. |

|

|

|

PTAC and radical were probably horrible examples. But I felt it got the gist across.

I too would like to see proper experiments using the different techniques. Might be difficult, but I'm imagining something like they do for testing performance parts with cars. Take a basic setup, note the performance, start changing things one at a time, noting the differences. But the problem is imagine would be testing the bedding. Depending on what is used, you might need to sand it off. That could have adverse effects once you reassemble. Most bedded barrels are not meant to come off easily. Would be a difficult experiment, but informative. |

|

|

|

Quoted:

PTAC and radical were probably horrible examples. But I felt it got the gist across. I too would like to see proper experiments using the different techniques. Might be difficult, but I'm imagining something like they do for testing performance parts with cars. Take a basic setup, note the performance, start changing things one at a time, noting the differences. But the problem is imagine would be testing the bedding. Depending on what is used, you might need to sand it off. That could have adverse effects once you reassemble. Most bedded barrels are not meant to come off easily. Would be a difficult experiment, but informative. View Quote I took apart a PSA 5.56 upper, FN chrome lined 16in 1:7 barrel. Trued the upper, bedded the barrel, shimmed for torque, YM N/M BCG. Groups with the same rounds shrunk by .4 MOA, just with those changes. It shoots 62gr Fusion pulls @ .5 MOA at 2950 fps over 25.9 grains of TAC in LC brass. (Western Powder 5.56 load) |

|

|

|

Was it PTAC? I've used PSA "premium" line of barrels and have yet to be dissatisfied. Anything not marked "premium" is a gamble to me. Then the PTAC line, don't get me started.

But, you could see a benefit from all these techniques even on the PTAC line. It certainly won't be match grade, but will go from just going bang to "hey I think i got target a few times". Doing these things to high end parts build is added assurance. I had my armalite upper checked, it was squared already. I swapped the 16" barrel, which wasn't the tightest, slid in nice and smoothly, for a 20" Armalite barrel and it was virgin tight. Felt good enough, so far seems very accurate. 500rds now and she's still looking new. I've ditched the carry handle, and am deciding on a scope. I don't think I'll need any of the enhancements for this rifle. I'm not going for 1000yds, or bench rest shooting with it. So all these things are a waste of time for this particular rifle because it won't be used as such. The Jack10 I'm doing might. I was thinking 338fed, but have been having second thoughts. I think i might go with the 6.5 or 7mm this time around. Will definitely use many of these techniques if I go that route. It all depends on what you want out of your rig |

|

|

|

Quoted:

I took apart a PSA 5.56 upper, FN chrome lined 16in 1:7 barrel. Trued the upper, bedded the barrel, shimmed for torque, YM N/M BCG. Groups with the same rounds shrunk by .4 MOA, just with those changes. It shoots 62gr Fusion pulls @ .5 MOA at 2950 fps over 25.9 grains of TAC in LC brass. (Western Powder 5.56 load) View Quote View All Quotes View All Quotes Quoted:

Quoted:

PTAC and radical were probably horrible examples. But I felt it got the gist across. I too would like to see proper experiments using the different techniques. Might be difficult, but I'm imagining something like they do for testing performance parts with cars. Take a basic setup, note the performance, start changing things one at a time, noting the differences. But the problem is imagine would be testing the bedding. Depending on what is used, you might need to sand it off. That could have adverse effects once you reassemble. Most bedded barrels are not meant to come off easily. Would be a difficult experiment, but informative. I took apart a PSA 5.56 upper, FN chrome lined 16in 1:7 barrel. Trued the upper, bedded the barrel, shimmed for torque, YM N/M BCG. Groups with the same rounds shrunk by .4 MOA, just with those changes. It shoots 62gr Fusion pulls @ .5 MOA at 2950 fps over 25.9 grains of TAC in LC brass. (Western Powder 5.56 load) And others will chime in with "PSA isn't PTAC, so your results are..." Yes, PSA's stuff is definitely above the quality level of their PTAC line, but that's beside the point. You compared an "as built" upper's performance to how it performed after doing the accurizing steps, which is exactly what the post you responded to asked about. |

|

|

|

Quoted:

Was it PTAC? I've used PSA "premium" line of barrels and have yet to be dissatisfied. Anything not marked "premium" is a gamble to me. Then the PTAC line, don't get me started. <snip> It all depends on what you want out of your rig View Quote |

|

|

|

Quoted:

Finally, a pre/post comparison, with actual results. Good for you. I'm curious what might have happened if you'd done each step individually (yeah, I know it'd be a royal PITA, but still...). How far off of square was the upper? What torque did you shim for? What kind of groups were you getting before? I'm still unconvinced that a BCG (that's in-spec) can have any affect on accuracy, but lots of people like Young's stuff. And others will chime in with "PSA isn't PTAC, so your results are..." Yes, PSA's stuff is definitely above the quality level of their PTAC line, but that's beside the point. You compared an "as built" upper's performance to how it performed after doing the accurizing steps, which is exactly what the post you responded to asked about. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

PTAC and radical were probably horrible examples. But I felt it got the gist across. I too would like to see proper experiments using the different techniques. Might be difficult, but I'm imagining something like they do for testing performance parts with cars. Take a basic setup, note the performance, start changing things one at a time, noting the differences. But the problem is imagine would be testing the bedding. Depending on what is used, you might need to sand it off. That could have adverse effects once you reassemble. Most bedded barrels are not meant to come off easily. Would be a difficult experiment, but informative. I took apart a PSA 5.56 upper, FN chrome lined 16in 1:7 barrel. Trued the upper, bedded the barrel, shimmed for torque, YM N/M BCG. Groups with the same rounds shrunk by .4 MOA, just with those changes. It shoots 62gr Fusion pulls @ .5 MOA at 2950 fps over 25.9 grains of TAC in LC brass. (Western Powder 5.56 load) And others will chime in with "PSA isn't PTAC, so your results are..." Yes, PSA's stuff is definitely above the quality level of their PTAC line, but that's beside the point. You compared an "as built" upper's performance to how it performed after doing the accurizing steps, which is exactly what the post you responded to asked about. The upper was a bit out of true, it took a few minutes to get contact on the whole front surface. I torque all my uppers to 40 lb-ft., while specs say you can go to 80 lb-ft I think anything over 40 lb-ft can lead to slight distortion. If it's true or not that's what I think. It was shooting 1 to 1.5 MOA before tuning it up. Now the 62gr Fusions run .5 MOA and the 70gr TSX @ 2930 are .8 MOA if I do my part of course. The craziest part about this rifle is the glass. A freaking UTG 3x9 Bug Buster $89 scope from Amazon I bought 4 years ago for a .22. Of course I dont use the turrets but it has not moved zero in 3 years. If you think your rifles going to shoot better, do you shoot better? Both my 6.8's can shoot .4 MOA groups, one has a Seekins ATC Comp on it, great comp but noisy as hell. I'm afraid to change it as I dont want to mess with what works so good. But its darn loud when hunting lol. |

|

|

|

I would love to see your sub .5 MOA 6.8's and sub MOA PSA upper complete the MOA challenge.

|

|

|

|

Quoted:

I would love to see your sub .5 MOA 6.8's and sub MOA PSA upper complete the MOA challenge. http://www.ar15.com/forums/t_16_17/51___ARFCOM_1_MOA_ALL_DAY_LONG__Challenge_.html View Quote Sure, I'll play with this this summer. These are all at 100 or 200 yards. Front bipod or bag, small rear bag. I dont own any mechanical holding devices. Heres one where I suck cause I pulled one.

Practicing different holdovers in 3 shot groups

Top group was hand load that was stringing, I did get it dialed in with a slightly different powder charge and OAL adjustment. 5 shot group is S&B 6.8 PTS factory ammo from my 16in Bison

This is one target from the 5.56 70gr TSX load. I use it for a mouse pad, lol. Not the best group I have shot but its the one I shot when a couple guys on this forum said I could not get 2930 from a 16in barrel with the 70gr TSX and be accurate. Its within Western Powders load specs for a 5.56 load. Yes, this is with the $89 scope. 10 shot group

Brass

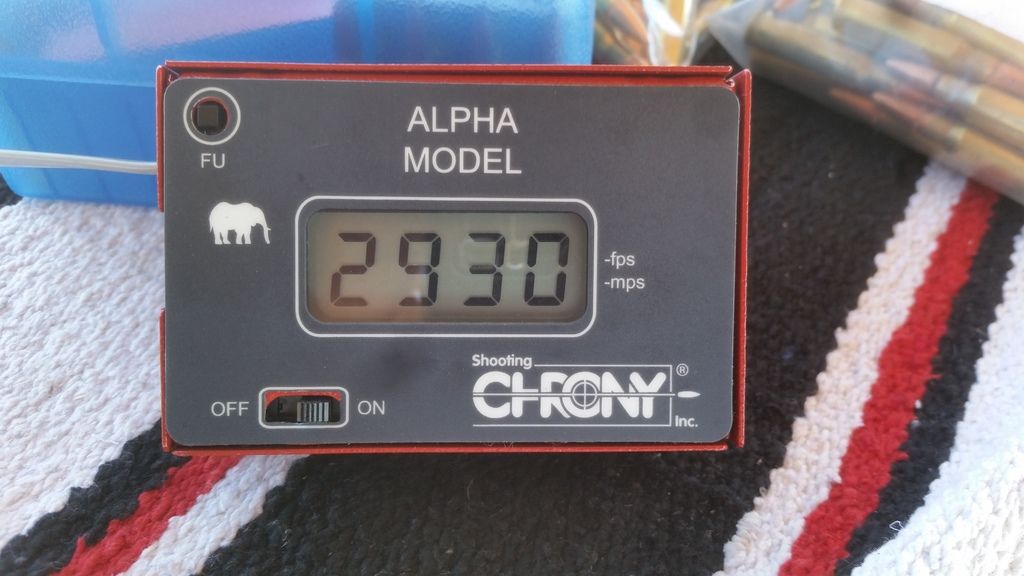

Crono

I shoot a lot from all 3 rifles. I research and test over 24 projectiles in the 6.8 but only 4 in the 5.56. I guess I just like playing with this stuff. However we should stick to the topic of the mechanical advantage of blueprinting your equipment. |

|

|

|

Quoted:

PTAC is Palmetto's "non-premium" line. Some might call it a "budget" line, but I don't have that good an opinion of it, given the reports I've read here. Palmetto's regular and premium stuff has always been great for me, though, even if their "premium" stuff seems to be just handled and packaged better. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Was it PTAC? I've used PSA "premium" line of barrels and have yet to be dissatisfied. Anything not marked "premium" is a gamble to me. Then the PTAC line, don't get me started. <snip> It all depends on what you want out of your rig My understanding was the premium marking meant it had been tested. Like individual HPT/MPT testing and inspecting. Add opposed to batch testing. I was thinking the regular stuff is batch tested, maybe multiples from that batch are tested. PTAC is only one test out of 100. I have no validation for that, just thinking of what i know of production lines and what not. I only get premium marked stuff from palmetto. Pretty much only barrels or bcgs if i can't find others in stock. PSA is my last resort. That's only for AR15 gear though. |

|

|

|

Quoted:

You, Mr. Red RTV, are a pioneer in the field sir. Look forward to your observations. Hope it helps. View Quote View All Quotes View All Quotes Quoted:

Quoted:

He got his money's worth, fair enough. You, Mr. Red RTV, are a pioneer in the field sir. Look forward to your observations. Hope it helps. Barrel clean and handloads ready, report this weekend. |

|

|

|

Quoted:

Barrel clean and handloads ready, report this weekend. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

He got his money's worth, fair enough. You, Mr. Red RTV, are a pioneer in the field sir. Look forward to your observations. Hope it helps. Barrel clean and handloads ready, report this weekend. |

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

He got his money's worth, fair enough. You, Mr. Red RTV, are a pioneer in the field sir. Look forward to your observations. Hope it helps. Barrel clean and handloads ready, report this weekend. Ever drive to the Range without checking the website calendar first? ....Closed all weekend for berm repair. |

|

|

|

|

|

Quoted:

Quoted:

Ever drive to the Range without checking the website calendar first? ....Closed all weekend for berm repair. I hate it when that happens. I have done that a handful of times. My range is 1,000 plus acres and I always get grumpy when they shut the whole range down for a match. Right now they are doing berm work on the 1,000 yard area. When I get my Grendel upper put together I probably won't have a place to test it out at 1,000. |

|

|

|

Quoted: You can shim, thermo-fit, spec out interference fit parts, and some do combinations of these. A reputable precision rifle shop isn't just throwing the barrel in and torquing it, then calling it good. Higher torque is another approach with the barrel nut. If you look at the AMU and where this originated when a guy saw flex in his extension as he moved the barrel at a match down in Australia back when they had A1s, you can learn more about where it originated. There was a good video posted not too long ago where this was all detailed. I know guys that do precision work who have been doing it for almost 20 years. They've even tried JB Weld, glass bedding, you name it. One in particular doesn't have to advertise, and has done a lot of work for people in a certain unit in the Fort Bragg area, and continues to do work for guys from there on their personal guns. He's an artisan with black rifles, not just an assembler. He currently sources under-sized uppers and over-sized extensions for precision builds, and still uses Loc-tite. The problem I see with this is a lot of novices jumping in and incorporating this into their normal assembly procedure, especially on their first guns, where they spent $100 on a garbage barrel from Jim Bo's Tactical Start-Ups, with a chamber that is below minimum spec, they don't quite get the concept of gas block alignment with the ports, and then expect sub-MOA performance. View Quote |

|

|

|

Quoted:

Quoted:

Quoted:

Quoted:

He got his money's worth, fair enough. You, Mr. Red RTV, are a pioneer in the field sir. Look forward to your observations. Hope it helps. Barrel clean and handloads ready, report this weekend. I took it (6.5 Grendel not a 308) out today. I had cycling issues (undersized brass) but the group wandering seems to have tamed down quite a bit. The barrel nut is not any tighter than it was before. Who knows, maybe the RTV will break down but I don't think it will. |

|

|

|

Quoted:

I first saw this with a JP barreled build I did. Couldn't get much better than 1.7" at 100yds consistently with it, and I suspected the barrel was capable of much better than that. I pulled it, lapped the receiver face, Cerakoted the upper, including the extension tunnel, and bedded the barrel with Blue Loc tite. Now it bug holes even with cheap 55gr in a new shooter's hands. Also, I re-built a friend's IRA .308 with Krieger barrel. Before, it was shooting 1.5" at best. After, it now shoots in the .6s with a random hand load, 5rd groups. Alexander Arms beds 20" and longer uppers. I've disassembled them. Ask anyone about trying to get a BCM upper apart. Les Baer does as well. GA Precision does. I've had them build 2 LRs for me, one in .308, the other in .260 Remington. Companies that are known for extreme accuracy do. Most of the companies you listed are mass-producers, not known for precision guns. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Just because the manufacturers you worked with didn't do it, doesn't mean there aren't reputable manufacturers doing it. I've seen it tighten-up groups on sloppy-fit extension-to-upper interface on several guns, both AR10 and AR15. There are other ways of skinning the cat from a manufacturing perspective, like specifying undersized extension tunnels in your uppers, and maximum spec ODs on your extensions. I know reputable manufacturers who do both interference fit and Blue Loc-tite to bed. I do it on all my precision builds. Maybe I'm just doing it wrong though. This 6rd + group was fired at 1000yds rapid, from an extremely lightweight Lilja Wasp profile 6.5 Grendel barrel. The whole rifle with optics weighs 7lbs 12 oz. empty. It's boring to shoot at closer distances unless you get on a shot timer and see how fast you can transition target-to-target. http://i1085.photobucket.com/albums/j422/LRRPF52/3bf6ee00-ad92-4600-a7bb-e77b0832f99f_zpsfe8pbfh3.jpg http://i1085.photobucket.com/albums/j422/LRRPF52/IMG_04191_zpsqlixp3o5.jpg Just to be clear, you assembled rifles, shot them, tore them down and reinstalled the barrel, and shot them again? What kind of improvement did you see? Not doubting you, just genuinely curious as to the results. Quoted:

It's done in both the .308 and AR15 world. Most precision builders will do it. They use loctite, rocksett, shims, or oversize barrel extensions turned down to fit. Done by whom? I don't know of a single one that does. Most builders & manufacturers like KAC, Noveske, Armalite, DPMS, Mega, Alexander, LWRC, POF, BM, BCM, Vltor, Rainer, and others do not. That's not to say it's not possible, but it does seem like if it was a cheap, easy, and verifiable boost to accuracy, more companies would be doing it. I first saw this with a JP barreled build I did. Couldn't get much better than 1.7" at 100yds consistently with it, and I suspected the barrel was capable of much better than that. I pulled it, lapped the receiver face, Cerakoted the upper, including the extension tunnel, and bedded the barrel with Blue Loc tite. Now it bug holes even with cheap 55gr in a new shooter's hands. Also, I re-built a friend's IRA .308 with Krieger barrel. Before, it was shooting 1.5" at best. After, it now shoots in the .6s with a random hand load, 5rd groups. Alexander Arms beds 20" and longer uppers. I've disassembled them. Ask anyone about trying to get a BCM upper apart. Les Baer does as well. GA Precision does. I've had them build 2 LRs for me, one in .308, the other in .260 Remington. Companies that are known for extreme accuracy do. Most of the companies you listed are mass-producers, not known for precision guns. Where did you find a lapping tool for an ar10? |

|

|

|

Used the blue on the most recent 6.5 builds of mine. Thread on the accuracy in here. Oh boy

|

|

|

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.