|

Posted: 10/19/2018 1:19:17 AM EST

EDIT: I decided to add this because I know 8 pages is a lot of time reading and I share a ton of longer posts.

If I can go from literally 0 knowledge about welding to being able to weld in all positions, with just about every process in a few years you can to. It's not for everyone, the pay isn't as great as its made out to be for the majority, the hours are long but it is rewarding and can elevate your life if you need a career path and don't know what you want to do or don't have a useful skill or aren't suited for the office life. The thread ahead details my personal journey, I try and share what knowledge I gained along with personal stories and tips I learned and a ton of pictures. Please feel free to ask any questions you have, and any criticisms are also welcome. Enjoy. So I had a thread in GD a while back, before I realized there was a specific forum for metal working so I'll post a link to that if I can find it, but I'll also share a lot of what was in it. This is gonna be a long thread, but there are a bunch of pictures if you just wanna look at that. To start off, I am no expert by any stretch of the imagination. I settled on a trade because I liked the fact that trades are always hiring, and they pay pretty decent. I know a bunch of guys who went the machining route, but math is not my strong suit so I looked elsewhere. I settled on welding because I'm good with my hands, and the idea of melting metal sounded cool. Never welded in my life, and had no clue going in what I was in for. So in late 2017 I had finally saved up enough to put myself through school, and I signed up for "Welding 101" which is an 8 week course. Started in August and being a moron, I did not realize at the time it was only 8 weeks so that was the only class I ended up taking that semester even though it ended in October. I learned the basics like brazing, and basic intro's into Arc Welding and Mig. We learned oxy acetylene welding first, and started the very first night which over 1/2 of the class was entirely unprepared for. I think me and one other guy had actually followed the syllabus and gotten all the gear, and welding rods. I fucking sucked at Oxy. It just did not sink in, and we had a short lecture and would spend most of the time in the lab welding. I don't have any pictures of the terrible welds, but you can probably google "shitty oxy acetylene welds" and find what my labs were looking like. But I tried, I stayed as late as I could, and just kept trying. We moved on to stick, and after hours of trial and error and a ton of stuck rods (the first few plates looked like a punji trap) it finally started clicking and I started getting the hang of it. However it still didn't look anything like what the other classes were turning in and especially not what my teacher was doing for examples. So after class I started Youtubing "stick welding basic tips" and "what not to do when stick welding" This video in particular was very helpful because he specifically did it wrong, and his bad welds looked like my best welds and I realized what I was doing wrong. I specifically was going to slow while long arcing, with a bad drag angle and not cleaning my welds enough and was getting a bunch of slag entrapment's and porosity. But by the end of the class, I had gotten Arc welding down pretty good but not great. This was my final. Just a basic butt, lap and T joint. We had a choice of Arc or Mig and most of the class chose Mig. I however spent so much time trying to master Arc I sucked really bad at mig and chose Arc. (some pictures are edited because we had to sign our names)   |

|

|

|

Was your welding all flat or did you do vertical and overhead? If you do vertical weld , do you start at the bottom and go up or do you downhand?

|

|

|

|

Quoted:

Was your welding all flat or did you do vertical and overhead? If you do vertical weld , do you start at the bottom and go up or do you downhand? View Quote The method varies depending on what your welding. If you are stick welding it's vertical up, which allows the metal to pool as you go. Mig can depend on if your using Flux core, or solid wire and can be both vertical up, and vertical down. The general rule is if there is slag you drag so you would do vertical up, and if your using solid wire on thinner metal you vertical down. If it's thicker you can vertical up which allows it to penetrate deeper |

|

|

|

And finally this fall they rearanged classes and what was offered and required to graduate with a full cert, and it fucked me over a bit. I had planned on doing ARC 124 and Tig but the Tig class was moved to spring, and 124 was only offered in the 2nd 8 weeks of the semester. So I had to wait until this week, and am now taking Arc 124 and Welding Blueprint reading.

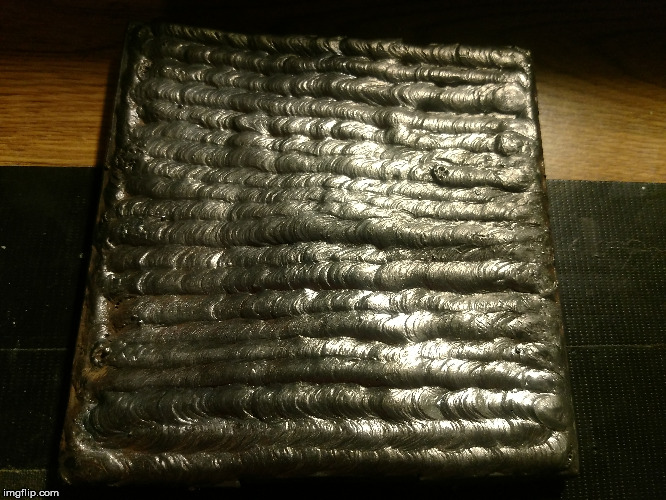

The blueprint reading is pretty self explanatory, but a side note I had to get a second book for this class. It's the only other textbook you have to get in this program, but is also 100. Arc 124 is where we will now be doing everything in out of position welds, vertical, horizontal and overhead. It's the last Arc class before I'll be doing a set of classes on qualifications. So to graduate I still have to do: WEL 130 Inert Gas Welding WEL 141 Welder Qualification Test I WEL 142 Welder Qualification Test II MAC 146 Metals/Heat Treatment WEL 145 Welding Metallurgy And I'll also end up doing Pipe welding which is no longer required but I think I want to do it anyways, and Mig 220 which is advanced and focuses on flux core and pipe welding with mig. So had my first class tonight in 124. Finally everyone but one guy showed up ready to weld. Teacher is no bs, and focuses on welding in the lab over reading the book which I like, though the same quizzes and written mid term will still happen. The class was informed that the class is from 5:15 until 9:25. Don't leave early under any circumstance and that we were there to weld. Which we did. Tonight was just a bit of cladding to show him our welds, so he can help us developed our skills. It was 4 hours of straight welding, no stop. (shitty time to have a pulled mussel in my back lol) We did two kinds of cladding horizontally. The first we basically just laid stringers spaced apart so he could see the individual stringers on a butt plate. The second we stacked welds in a normal cladding with all sides up to the edge welded. Here's one that I took a pic of.

I was kinda pissed after I realized that my electrodes had some moisture in them, and it caused a few wormholes. He recommended we all stop using shitty northern tool electrodes and go get some Lincoln Excalibur and gave me a handful. They were noticeably better. So ya, if your interested in this I'll keep updating it with pictures and what were doing. If not, that's cool too just say so and I'll stop posting stuff. If you have questions about going to school I'll try my best to answer and if you really want, I can also post stuff like the quizzes so you can brush up or learn something new. |

|

|

|

If you continue with stick welding make a hot box to store them in, just a lightbulb will do. ( If you have some that you think may be damp a toaster oven will fix them in a jif.)

Makes a huge difference and yea stay away from HF electrodes. |

|

|

|

I took that class in 2006.

Now using it in 2018. Never know how things will turn out... |

|

|

|

Wow, great thread, thanks for posting a very interesting and informative thread. Will follow.

My son is a certified welder and enjoys it very much, I started him welding at 7 years old and he just took to it. He is 21 now. |

|

|

|

I'm a "hobbyist" welder. Took a class at a local community college. However I think if I were a tradesman I would want to be a certified welder.

Tagged for updates. Thanks and keep up the good work! |

|

|

|

A friend in my car club at the time was a welding instructor at a community college. He came to my house and taught me how to weld with my equipment. Luckily, I bought the Miller buzz box, much better than the tombstone Lincoln. I loved me some 7018 rod and burned a lot of it. I haven't stick welded since the 90's. All I do is gas cut, plasma cut, and Mig these days.

|

|

|

|

Cool thread.

I'm an electrician, but took some welding classes at the local community college just for myself. You're right on about the guys that want to just do the minimum. I will say though, that our classes were much more class room focused than lab. We covered metallurgy, prep, filler selection, weld theory, etc. It was good since the actual welding part is really the easy part, on the other hand, troubleshooting when you run into issues is important too and we missed out on a lot of that. I took a break and have just been welding at home for the last year , so I plan to start back up in the spring semester. I think that's the best way to go if you can swing it. Get the basics down, use what you learned, then go back and learn some more. Being able to apply what I learned helped a lot more than just doing a bunch of coupons. Not saying that doesn't work, but bouncing around between different welds helps the information stick for me. |

|

|

|

NovaLabs/Makers in Reston has Mig and Tig and will teach intro safety classes. Once you've been signed off on the tools, your free to use it without supervision. Not certification classes, but people have used the lab to practice to get certified. Full Disclosure: I'm the backup Mig instructor and working on Tig classes.

PM me if you want more info. |

|

|

|

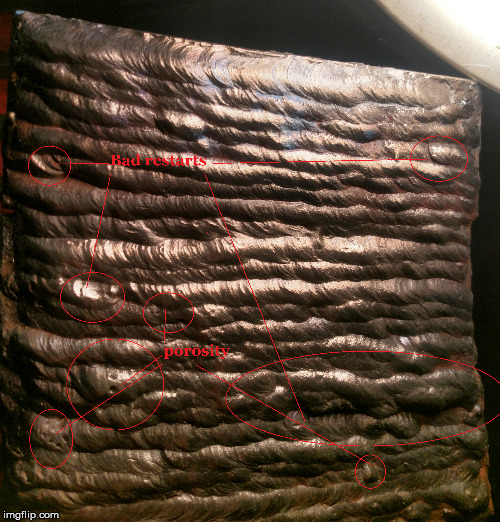

Part of being a student is not knowing what I don't know, so if I missed something don't be afraid to say so because I can't learn from a mistake I didn't notice.

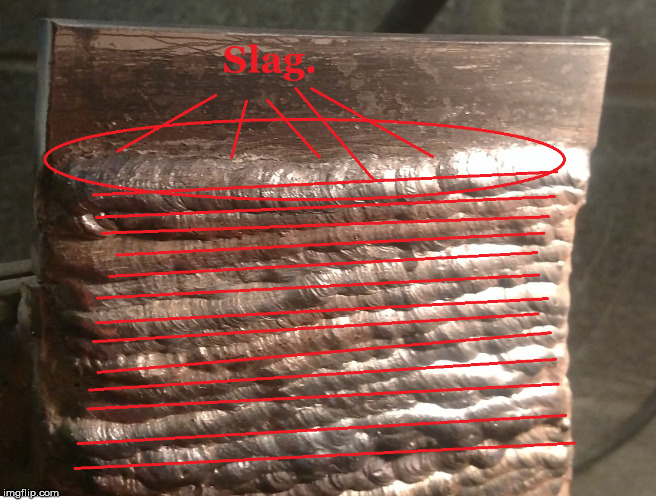

Here's some stuff I noticed just looking at a few of the pictures. Overall I'm not terribly upset that it didn't come out as nice as normal, because this is only the 2nd time I have vertical welded (did if for maybe 30 mins last thurs). Eventually I'll be able to get the drag angles right the first time, and won't have as many problems with bulging.  So I highlighted the slag on this, to show you just how irritating the Hobart electrodes can be. Even though the weld was fine, the slag did not break clean and required a fair amount of chipping. This picture was actually taken after being chipped, and cleaned with a wirebrush. Even after that there were still pockets of slag that had not come off. If you neglect this, you will have problems. The second part, is a bunch of red lines. This is an example of what I was talking about with not being able to see well. When you have a shit helmet, you can't see shit. So for myself, I would lay a great bead that followed the previous line pretty well. Only problem was the previous line was not straight which leads you to having crooked lines.

This is what Slag should do, and what it does when I use the nicer Lincoln electrodes. This is another example of electrode problems. The biggest problem I was having on the vertical was the starts. Using the shitty Hobart rods I was having a problem getting them started, and having to pretty much scratch start and that was causing me to stick them, which required breaking them off, and when you do that, you make a small hill. Do that enough and you get a bulging start. I just could not get those electrodes to start worth a fuck, and it showed. Once I got it going it wasn't too bad at all but almost all the starts suck.

|

|

|

|

This was one of the videos we watched. Again this teacher does not care to much for the lecture side of things because at this point, just about everything has been covered in the previous classes.

Horizontal Stick Welding E7018 This was the second video, just to give us an idea of whats coming up in future classes.  Stick Welding Tips- 7018 2g Plate Test |

|

|

|

Quoted:

Cool thread. I'm an electrician, but took some welding classes at the local community college just for myself. You're right on about the guys that want to just do the minimum. I will say though, that our classes were much more class room focused than lab. We covered metallurgy, prep, filler selection, weld theory, etc. It was good since the actual welding part is really the easy part, on the other hand, troubleshooting when you run into issues is important too and we missed out on a lot of that. I took a break and have just been welding at home for the last year , so I plan to start back up in the spring semester. I think that's the best way to go if you can swing it. Get the basics down, use what you learned, then go back and learn some more. Being able to apply what I learned helped a lot more than just doing a bunch of coupons. Not saying that doesn't work, but bouncing around between different welds helps the information stick for me. View Quote Even in this class, the younger guys just out of HS are the ones who are mad that they have to stay until the end of class. I took like 3 smoke breaks in the 3 hours in the lab and there were always 4 or 5 guys standing around on their phones bitching about having to stay. I should also clarify that in the previous classes, there was a good amount of classroom lecture and book work. I would say in the 8 weeks we had around 7 quizzes, and a usually 80 question mid term. We had to obviously learn the safty stuff, but in each class there were a good deal of lecture on how to deal with setting up the welders, stuff like explain the differences in DC and AC and all that, and the causes and effects of arc blow, long arcing and all that. This is the first class that we have had around 30 mins of lecture, and then straight to the lab. I like it that way personally because I am very hands on. I can read something a million times but until I do it myself, it doesn't sink in. |

|

|

|

Tag to follow. Welding is something I’ve been wanting to learn. No time currently, but hope to get there.

|

|

|

|

Neat thread. Maybe I can take some welding classes in a couple of years.

|

|

|

|

Quoted:

Neat thread. Maybe I can take some welding classes in a couple of years. View Quote Nothing to really report today, Blueprint reading was as boring as usual but I was pretty irritated because we had 14+ pages of homework to do from Monday to Today. I was still working on them at work today, and we all found out from our teacher it's because she want's to go to a casino for the entire week of Thanksgiving. So were rushing through stuff so we won't have to come to class at all that week

Between work, and my other class the amount of take home stuff was kinda outrageous. But I will be picking up 5lbs of the Lincoln Electrodes tomorrow, and I'll include the price if anyone is interested. |

|

|

|

Nice! Learning is occurring! That's always good to see.

Definitely agree with getting good electrodes. Shit electrodes are just frustrating, especially starts. Start your arc strike further ahead than the start of the plate, further ahead than you think until you get really consistent with starting up, and move back. Arc strikes will leave you busting a test, so get used to keeping your arc strikes ahead, long arc it a bit back to where you want the bead to start, and move forward from there. If you can swing a cheap used vertical rod oven off youtube, grab one for low hydrogen stuff (7018). The "lightbulb in a pipe" thing doesn't get hot enough. A 60 watt lightbulb isn't gonna get the oven to 300-350 degrees. Downhill 6010 is super common in pipe welding, so practice that as well. 7018 uphill is common, but anyone who says you can't weld stick downhill is just wrong, and there are definitely times where it's preferable and even called for in the WPS. Something that always helped me with keeping stringers straight, do your first one right on the edge of your coupon so you have a known straight line to follow. For every subsequent stringer, provided your bead width is consistent, use the toe of the previous weld as your "straight" line. Trying to stack beads next to each other always had me screwing up. Since tests will want a certain amount of overlap on your fill and cap passes, it pays to get used to using the toes of your previous beads as your reference. Obviously you've gotta do whatever your instructor wants for the lab, but for practice, definitely train like you're gonna fight. And while you're learning, don't hesitate to take a straight edge and your soap stone or scribe and mark a straight line to follow. Every little bit helps when you're learning. Jody Collier has probably some of the best welding videos on youtube. That, "enough amperage to hold a tight arc, then hold a tight arc" that he's always preaching really is the best thing you can do on stick. Weldtube is pretty alright too, Hjalmar Aguilo talks too much and his videos are way too long, but there's good information. I have trouble listening to Bob Moffat from Weld.com but he knows his stuff if you have the patience to listen to him kind of drone on. Don't bother with the "Mr. Tig" weld.com videos. Dude is clownshoes. Jacob Schofield has some good pipeline videos. He's hard to follow sometimes but there's good info to take as well. He also shoots, which is always good to see. If you are able, bring a grinder with a brush wheel on it as well as a rock disc and flapper wheel. Makes getting rid of slag SUPER easy, gets you back to burning rod faster, which in turn means more practice, and better welds. I always have at least 3 grinders at the ready, one with each type of wheel. Not having to swap wheels while you're working is great. And ALWAYS GRIND YOUR STARTS!!!! Good job picking up a nice hood. It definitely helps lots. I've got a fantastic Optrel that's amazing indoors. It will do everything from low amperage tig to hot and heavy stick. It drives me NUTS outside if the sun is behind me. There's JUUUUUST enough light leak reflection that it messes with me. Outside I use a Wendy's Pancake with an ArcOne singles. Not the cheapest solution, but the best thing I've found for welding outside, and I don't need to be able to weld low amperage tig so the shade 10 is perfect for pretty much everything else. Pick up a set of cheaters if you want too, it brings the work closer without having to stick your head in it, even if you don't need glasses. Doing great man, keep up the good work! Welding is a fantastic skill to have, even if it never becomes a profession. And as much as the blueprint reading is a pain, it's a necessary evil, and the better you are at it, the faster you can work, and the more accurate your work will be. |

|

|

|

|

|

Quoted: That had to be someone else. My current medium is Legos. The closest I've come to welding is Fluffy has me trying to silver solder a Flat Spot lower. View Quote |

|

|

|

Thanks for taking the time to take the pic and write up the posts. Very good stuff!

|

|

|

|

Quoted:. It was haha. One of my persona goals though is to be able to reweld a cut up gun (I assume thats what you mean by a flat spot lower) View Quote |

|

|

|

View Quote

|

|

|

|

OK so it's Tuesday, and that means welding time.

Tonight was somewhat irritating, because our teacher was out for the entire class tonight so we had to wait until the other teacher finished his lecture to open the shop up for us. So we didn't get inside until 6:45ish. We were just working on the same project as last Thursday. My phone is aving some serious battery problems, so I was unable to take many pictures tonight as it kept dying and I was having to charge it in the booth. I was also pressed for time. I will have all three done by Thursday, but these troughs take a considerable amount of time to do, so I'm looking forward to doing the cuts and seeing just how well I did. I have been taking a bit longer to do these, because I am shooting for welds that would pass a qualification test, and I don't want any slag inclusions so I'm being very careful to thoroughly clean the work before each weld. A fair number of the class is trying to get by with doing as little as possible, and in particular they made their troughs as narrow was possible so it would require less time, and fewer passes. I took a picture of one of the other guys who is actually doing it correctly (and his look really good), and It also got another of the guys who is trying to do as little as possible and you'll see what I'm talking about. I'll include a quick paintshop of how I was taught to make the trough, in case anyone want's to try their hand at it for fun. This is the correct way to make one. You weld the outside corner first (the bottom of the V) first, and then you tack both ends to the plate. We were taught that you should try and shoot for a 90* angle as best as you can, and to use anther coupon as a test piece to make sure you got it right. After making your initial tacks, you use a 3rd piece to check and see if your at a 90* and if the coupon firs flush, your good and you weld. If it doesn't then you either hammer it apart or together until your as close as you can get. Then you flip it upside down, weld down the outside corner, flip it back over and weld it to the base plate. And this is what a bunch of the younger students are making. I don't really get the point in doing this, because before we even started he specifically told them not to make them too narrow, and if you did you would be re-doing them all.

Anyways here's a few from tonight, not in any particular order. Horizontal. I ground some off as one side was getting a bit higher than the other.

First pass after coming back today on my flat position trough.

Same thing, got a little higher on one side so I evened it out some.

I thought about ending it here, and this was going to be the final reveal but after I got done I was talking to my old teacher, and he suggested doing one final cover pass because one side is slightly lower than the other. I could have left it, but I decided on Thursday I'm going to do a new cover pass.

I took a picture of it cleaned off, but of course my phone died while taking it so it didn't save correctly. It came out looking really great, but I'll end up doing one final line almost completely across just to eliminate the slight decline on one side. I think it was getting up there in the number of passes that I ended up making, and I would assume there was no less than 50 in this one piece alone. So many electrodes

And this is the "homework" table, just laying everything out to be graded. I'll highlight what I was referring to and where mine are in the next photo.

|

|

|

|

Nice work and congrats on the class! great pics too

I took a gsmaw class a long time ago. Mine was every Saturday for 3 months 7am-1pm. People would finish the project and leave. Instructor would just shake his head. People who wanted to stay could, outstanding students were allowed/encouraged to take union welding test. Instructor was a retired Nuclear Welding Inspector. The more rods you burn the better you get. I would stay the entire time I figured I was paying for it might as well. I would leave and go straight to work, I was the "welder" at my job and once I got my certificate that is primarily all I did. I self-taught myself vertical and overhead by just doing. I was teaching myself TIG as well and doing real well. MIG was difficult because you could never get the gun set up right, and once you did someone would fuck it all up. So I just let others MIG. We used cover gas so they would made birdshit and grind it down. We built a hot box using a light bulb as someone suggested. It worked great, I had plastic rod box (tube) I would take what I needed for the day and return them to the box after wards. During the summer we would spray them with hairspray to seal out the humidity a trick told to me by my welding instructor. They say doing either isn't a great idea, but when you do not have the option of popping a new tin or box of rods every time you arrive at a jobsite it is the best alternative. |

|

|

|

So to sum everything up, I feel like I'm getting better each class but obviously I still have a great deal more to learn. I am however feeling a lot more comfortable with my out of position welding, and especially my horizontals. I have not spent as much time in vertical yet, as these troughs are just taking a ton of time to do, but I'm fairly confident that I'm going to be able to at least have a decent one but it may not be as good looking as the flat and horizontal ones.

It was kinda cool getting to know everyone in the class a little bit better seeing as we had over an hour to kill before we could get into the lab. The guy whose work I highlighted with an arrow on the left side is a really cool dude, and showed us some cool pics of his time in the military. Another pretty interesting thing I noticed, is even the guys who are just out of high-school are all really into shooting as that was something we all talked about for a while. And surprisingly just about everyone has their own tannerite story's haha. While the rest of the academia is at a race to the bottom, its pretty nice to know that just about everyone I have had classes with has been a definite conservative and almost all have been somehow involved in shooting sports in one way or another. There were even some MAGA hats in my last class, and just about every truck/car/suv that parks where most of us who are going to school for either welding, or machining has NRA, Trump or some other gun related stickers. Anyways, all that aside the grinder I picked up over the weekend has helped considerably, as I now just use that to wirebrush clean every weld instead of taking the time to chip and then hand brush each weld. It's a definite recommendation if your going to school, or even just recreational welding. Again, if you have any questions or comments, feel free to ask or whatever. I'm always ready to hear advice or critiques. More to come Thursday |

|

|

|

Quoted:

Nice work and congrats on the class! great pics too I took a gsmaw class a long time ago. Mine was every Saturday for 3 months 7am-1pm. People would finish the project and leave. Instructor would just shake his head. People who wanted to stay could, outstanding students were allowed/encouraged to take union welding test. Instructor was a retired Nuclear Welding Inspector. The more rods you burn the better you get. I would stay the entire time I figured I was paying for it might as well. I would leave and go straight to work, I was the "welder" at my job and once I got my certificate that is primarily all I did. I self-taught myself vertical and overhead by just doing. I was teaching myself TIG as well and doing real well. MIG was difficult because you could never get the gun set up right, and once you did someone would fuck it all up. So I just let others MIG. We used cover gas so they would made birdshit and grind it down. We built a hot box using a light bulb as someone suggested. It worked great, I had plastic rod box (tube) I would take what I needed for the day and return them to the box after wards. During the summer we would spray them with hairspray to seal out the humidity a trick told to me by my welding instructor. They say doing either isn't a great idea, but when you do not have the option of popping a new tin or box of rods every time you arrive at a jobsite it is the best alternative. View Quote But ya, the thing a lot of the younger guys (not all and some older ones) fail to realize is that you are only hurting yourself in the long run by taking shortcuts, and not putting forth the effort to actually learn the material. I know a lot of people in not just this program but in the regular community college classes as well use the FISA grant as a free money, and since they are not having to pay a dime to attend, or buy books AND they get a couple grand out of it, they tend to either half ass it, or drop out after a month. I have noticed that the people who really want to learn, who stay as late as they can and do as much as they can are by and large the guys who are paying out of pocket and coming in directly from work. I know I personally can only afford two classes a semester usually, so I personally take full advantage of every opportunity to use the welders and also to learn as much as I can. I realized very early that it takes me a little while to learn what I'm doing, and I can't just come in and hammer out the lab in an hour and leave, because it won't sink in at all. I also look at it like I want to know my shit, because I'm eventually going to be out there looking for work as a welder, and If I can't set up the machine, if I can't do a vertical weld or if I don't understand whats wrong with my weld I won't even make it out of the interview let alone get the job. And to top if off the school was graduating people that had no fucking clue what they were doing, and all the local company's were wondering looking at an applicant from the program very skeptically because they kept getting "graduates" that had no idea how to make even the most basic welds, couldn't turn on a machine and were just embarrassing the school. So I know that going in, the company is probably going to be skeptical and I'm going to have to prove that I know my shit. I personally like being able to weld from 5:45 until 9:30, because I'm only in the lab twice a week, and only for 8 weeks. The more time I spend in there the more I'm going to learn and hopefully the better I get. For the past few classes, there is only one or two other guys who leave when I do at 9:30. The guy whose stuff was to the left of mine (the vet) and another younger guy. I know that even when my welds were shitty, the fact that I was staying late helped my grade considerably. The teacher I have in this class is actually an owner of a pipe welding company, who actually went to the program director and was like what the fuck are you teaching these kids, they have no clue how to weld. They said well do you think you can do it better, and that's how he got the job. What really pisses me off is the fuckups who take a spot in class, which is a very limited number of openings and drop out by the third of fourth week. I had to beg the administration to let me in the Arc class I'm in, and the teacher agreed to overload the class to get me in. He was supposed to have 16 or so students, but by tonight there was MAYBE 10 people. |

|

|

|

Older folks tend to have a very different attitude towards schooling. They've decided the opportunity cost is worth what they're going to get out of it, and are there to learn. Young kids don't even know the term opportunity cost.

I was very jealous of the young Arabs in my Arabic class that were taking it for an easy A. I was there to get through 101 & 102 so that I could transfer it back to A&M and finish my degree after 20 years. I suck as a language student and am very proud of my C in Arabic 102. |

|

|

|

So I'm a little annoyed by a couple of things. The first and the one that's really getting to me is this teachers, teaching style.

I know every teacher is different, and teaches in their own way, but this teacher really needs to re-evaluate the way hes teaching this class in my opinion. This is supposed to be advanced ARC, the class we have right before we start taking qualifications and where details count. This is why I am personally taking my time, to make good and quality welds and a finished product that I know I put 100% into, and a product I can feel good putting my name on. I'm not cutting corners, I'm welding as we were taught in every other class. But that's not what he wants.. He told me to stop grinding my welds when I don't like the uniformity, or think there may be a defect. He told us to weld the plate continuously even if its glowing, as he wants the troughs filled up and there are no "too hot" of plates. He then tells me in his next sentence that while there is a temp range on the qualifications, just to weld these hot. I said something like "I get it, but I also want to be able to pass a qualification test, so I treat these as if I am welding to pass one" and he then asks me if I quenched them. I replied I hadn't, and that we were taught never to water quench because it affects the metal. I had let it cool outside under the fan for a few minutes. He jokingly said something like I would fire you for taking to long or something like that.  I don't fucking get it. In every other class we have been taught one thing, and hes basically telling us to throw all that out and for lack of a better term, weld as fast as possible and let whatever happens happen. So I did it his way on my vertical, and basically just continuously welded no matter how hot, how shitty the beads started to look and how I think its going to turn out. Anyways, I just don't personally see the point in half assing something, but Its his class. I feel like advanced means we put forth the most effort as possible, and get it right the first time. And on a funnier note, I was right about the people who tried to cut as many corners as possible. I don't think anyone other than me and the vet passed the cut test. One dude next to me started yelling, cussing and throwing shit in his booth which was pretty damn funny. He had failed every one of the troughs, and was getting pissed because he was having to do all of them over again and even the new ones, after a few passes were getting thrown in the scrap bin and he was told to restart. So ya, I guess we'll see how it goes, I don't have a personal problem with my teacher or anything like that, it's just the method of teaching this class seems diametrically opposed to every other one. |

|

|

|

He's telling you that you're good; now you have to learn fast. So learn fast.

|

|

|

|

Quoted:

He's telling you that you're good; now you have to learn fast. So learn fast. View Quote |

|

|

|

Quoted:

Also in the real world, its about production, i had a teacher say sometimes it doesn't have to be perfect, just structurally correct. Echo he is saying you've got it, now get it done in one pass. View Quote Like I said I didn't take it personally or anything, it was just kinda confusing to have been taught one thing in all the other classes and then be told to do things differently. It will be interesting to cut the vertical trough for sure. I'm still wire brush cleaning each pass, but I was burning rod in as fast as I could make a pass and clean it. I hope it will be as good as my other work, and if its not it's something I'm gonna have to work on because I do want to get to a point where I can do it right the first time, without having to grind anything out. |

|

|

|

Pushing to weld it fast will give you experience with hot steel. It happens sometimes in the real world and you have to know how to deal with it and get the job done.

Welding as a trade covers a huge variety of work. Most people first think of pipe welding, but that's just a tiny fraction of what's out there. I've held both structural and pipe certs. Never actually needed any of them, but they gave me experience. Spent 3 years repairing heavy machinery and industrial equipment. Then 10 years on my own doing farm related stuff. If you're looking to make money, there are two ways to go. You can specialize and strive to be the best in your field. Or you can get good at everything and never be out of work. I like to design, build, and fix shit. So I went the second route and will take whatever is thrown at me. I don't regret that decision one bit. |

|

|

|

Quoted:

Pushing to weld it fast will give you experience with hot steel. It happens sometimes in the real world and you have to know how to deal with it and get the job done. Welding as a trade covers a huge variety of work. Most people first think of pipe welding, but that's just a tiny fraction of what's out there. I've held both structural and pipe certs. Never actually needed any of them, but they gave me experience. Spent 3 years repairing heavy machinery and industrial equipment. Then 10 years on my own doing farm related stuff. If you're looking to make money, there are two ways to go. You can specialize and strive to be the best in your field. Or you can get good at everything and never be out of work. I like to design, build, and fix shit. So I went the second route and will take whatever is thrown at me. I don't regret that decision one bit. View Quote I'm planning on doing a few extra classes, that are actually not required to graduate. Pipe welding, and flux core, Advanced Gas Tungsten Arc Welding, visual testing and a couple more. I figure if I can hold certs in as many things as I can I'll have the best luck getting a really good job. |

|

|

|

The thing with certs is that they may help give you a little credibility when applying, but most companies are going to test you themselves. So practice up. You need to be good all the time. Not just on test day.

Experience and hood time is what you need. I went to a CC two years. First year was spent mostly in the lab 8-3 m-f. Structural certs with gmaw, fcaw, and smaw weren't much trouble, but smaw on pipe was giving me fits. Was only able to pass a few of them. Second year was spent as a teaching assistant while taking my other classes. At the end of that, I tried pipe again with the students. This time I flew through each test like I was born welding pipe. So get all the hood time you can and stick with it. It makes a huge difference and is definitely a perishable skill. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.