|

Posted: 6/2/2024 5:03:29 PM EDT

My neighbour has an ancient husky brush saw that he lost the gas cap for.

They are made from unobtanium apparently and if I can figure out the thread size, pitch it wouldn't take long to make him one. |

|

|

To say that you are on thin ice would be a vastly optimistic view of your current situation. The ice has melted. You are being supported by the surface tension of water.

|

|

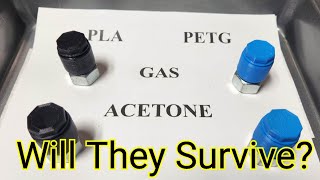

[#1]

PETG would be impervious enough. Worst case you make him a new one in 5 or 10 years

The original is probably abs or nylon. |

|

|

|

|

[#2]

|

|

|

To say that you are on thin ice would be a vastly optimistic view of your current situation. The ice has melted. You are being supported by the surface tension of water.

|

|

[#3]

Maybe he won't lose that one

|

|

|

|

|

[#4]

PETG. Be aware GITD filaments are abrasive and the GITD bits may not have the same impervious properties. Best to make it pure PETG.

|

|

|

|

|

[#5]

|

|

|

|

|

[#6]

|

|

|

|

|

[Last Edit: Tholo]

[#7]

This question does come up a lot. The conventional wisdom is petg for chemical resistance.

Here's 92 octane nonoxy gasoline with petg, petg cf, asa and nylon filaments. They're not in direct contact with the fuel. The lid isn't sealed so it won't build pressure. |

|

|

|

|

[#8]

I have oiled the f out of my PLA tough Glock frames, shot them for 400 rounds.

2 years later still showing no signs of degradation. |

|

|

"According to Argonne National Laboratory, it takes 100 pounds of battery in an EV to go a distance achieved by only one pound of gasoline in an ICE vehicle"

|

|

[Last Edit: Tholo]

[#9]

Functional print Friday on YouTube went through some of his prints that had been in service for years. All PLA I think.

This guy is basically doing the same experiment I kicked off. I haven't finished the video yet.  PETG 3D Printer Gasoline and Acetone Test Go to about 11:00 for the results. He includes chapters in the video, which is nice. Surprising result, the petg absorbed the gas. It looks like it would disintegrate eventually. PLA held up better to the gas over the 8 hour test. |

|

|

|

|

[#10]

Pa12 is also resistant to oils

|

|

|

|

|

[#11]

|

|

|

Tennessee Squire

|

|

[#12]

Originally Posted By SandHillsHillbilly: Doesn't that require a high temp enclosure to print? View Quote View All Quotes View All Quotes Originally Posted By SandHillsHillbilly: Originally Posted By bionicmonkey: Pa12 is also resistant to oils Doesn't that require a high temp enclosure to print? Op didnt state any reasonable limits.. its not like peek or pekk.. 280f and hardened nozzle. |

|

|

|

|

[Last Edit: Tholo]

[#13]

Nylon needs to be dry dry dry. (Nylon is polyamide, PA. There are a couple of common types)

PA12 is less sensitive to moisture than PA6. I don't think it needs an enclosure to print, but I've never tried without. |

|

|

|

|

[#14]

Originally Posted By Tholo: Nylon needs to be dry dry dry. (Nylon is polyamide, PA. There are a couple of common types) PA12 is less sensitive to moisture than PA6. I don't think it needs an enclosure to print, but I've never tried without. View Quote Yes you'll want an enclosure for nylon. Otherwise it will try to outwarp Hunter Biden's mind. |

|

|

|

|

[#15]

|

|

|

|

|

[#16]

Originally Posted By -Obsessed-: Yes you'll want an enclosure for nylon. Otherwise it will try to outwarp Hunter Biden's mind. View Quote View All Quotes View All Quotes Originally Posted By -Obsessed-: Originally Posted By Tholo: Nylon needs to be dry dry dry. (Nylon is polyamide, PA. There are a couple of common types) PA12 is less sensitive to moisture than PA6. I don't think it needs an enclosure to print, but I've never tried without. Yes you'll want an enclosure for nylon. Otherwise it will try to outwarp Hunter Biden's mind. Havent had that experience with polymaker. I run pa6 at 300 but the enclosure open. |

|

|

|

|

[#17]

|

|

|

|

|

[#18]

|

|

|

To say that you are on thin ice would be a vastly optimistic view of your current situation. The ice has melted. You are being supported by the surface tension of water.

|

|

[#19]

It's been a couple of days since I put the filament samples in the gasoline. The last 40 hours they were in direct contact with the gas.

They all seem the same as when they went in. Not squishy or brittle. PETG, PETG CF, ASA, AND PA6 Nylon. |

|

|

|

|

[#20]

ABS most certainly is not. Gas can cap printed from ABS had a little to good of a seal and this is the result.

|

|

|

|

|

[#21]

Originally Posted By -Obsessed-: What size parts? And what bed surface and bed prep? CF or regular? I forget which brand I used but it was a Taulman (sp?) alloy of some type. View Quote View All Quotes View All Quotes Originally Posted By -Obsessed-: Originally Posted By bionicmonkey: Havent had that experience with polymaker. I run pa6 at 300 but the enclosure open. What size parts? And what bed surface and bed prep? CF or regular? I forget which brand I used but it was a Taulman (sp?) alloy of some type. I've run Polymaker PA12-CF without an enclosure. 280C for nozzle, 50C for bed (225x225). Filament is dried for 12+ hours at 70C. Hardened steel nozzle as well. I get some shrinkage, but it's pretty minimal, probably around 2% and I'm thinking I could fix that with Cura settings (vertical and horizontal scaling). I've only used it for small parts though (less than 2" cube size). |

|

|

I ain’t in no ways tired of winning yet!

|

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.