|

Posted: 10/16/2017 3:23:24 PM EST

As I said in another post. I am looking for some cheep ways to allow children to shoot my 50.

I was thinking about plastic 3D bullets and just primer for propellant may work Anyone try this or even know where I could find the 3D bullets? |

|

|

|

Quoted:

Sorry I don't have an answer for you. I did see this video: http://www.youtube.com/watch?v=4a1SC2vBGM4 I gladly print you 5 to test if you want, as long as I get it in writing that you won't sue me if something goes wrong.

The only advise I would have is make sure you clean the barrel with something that will dissolve the plastic your using before going back to a normal load. View Quote |

|

|

|

Quoted:

Sorry I don't have an answer for you. I did see this video: http://www.youtube.com/watch?v=4a1SC2vBGM4 I gladly print you 5 to test if you want, as long as I get it in writing that you won't sue me if something goes wrong.

The only advise I would have is make sure you clean the barrel with something that will dissolve the plastic your using before going back to a normal load. View Quote |

|

|

|

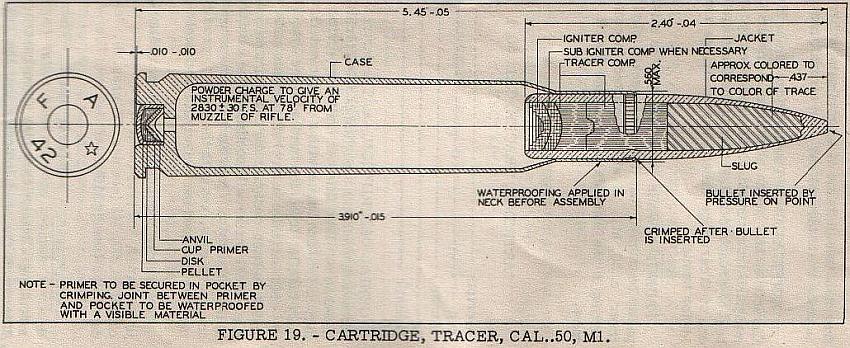

I found this Image for a tracer round. Do you think it will work?

From Site: http://www.pt103.com/PT_Boat_Components_Browning_50_Cal_M2_Aircraft.html |

|

|

|

|

|

|

|

I'll print them in the morning. IM me your address. I'm printing them in ABS, so acetone should be able to dissolve any residue left in the bore.

|

|

|

|

|

|

|

|

Awesome guys. Hope it works. If it does can you give some crono data Rickypool?

|

|

|

|

I can if I can find my cronograph in my gun room.

I plan to at minimal take pictures and post them here |

|

|

|

Any way to make them heavier? Different materials?

Wonder if a jacket could be swagged onto one? |

|

|

|

Maybe if they could be made hollow and filled with jb weld or something..

|

|

|

|

a little different, but I remember reading about someone doing this in 38 special. Plastic bullets from a mold, just primer. accurate inside the house and safe for practice.

One of the other things I have heard/read about is wax. may be able to get a mold made up and cast them in wax, then use the primer to fire. |

|

|

|

I have a lot of the 38 plastic bullets and cases for my 38 revolver and they work great as practice.

I have used wax as well. The wax only work with straight walled cases and the wax pushed all the way to the primer. I have even used foam ear plugs out of the 50 bmg but not work so well. Only went about 15 feet. |

|

|

|

Obviously you're going to down load these, be sure to use some case filler. I wouldn't use much if any crimp as it could cause them to snap in two. Have a good chamfer on the mouth of the case so it slides in easy....

As for making them heavier, I was thinking that you could hollow them out to an extent and then back fill with fine lead shot. Epoxy them closed and then see what happens? Probably more work than they're worth... |

|

|

|

Quoted:

@Rickypoole They are ready. https://www.AR15.Com/media/mediaFiles/23653/IMG_2181-336058.JPGhttps://www.AR15.Com/media/mediaFiles/23653/IMG_2182-336059.JPG Edit: They came in at around 90 grains. View Quote |

|

|

|

|

|

Was it mentioned the barrel length. Kinda wondering how much barrel those will pass through with a primer alone.

|

|

|

|

Got them "loaded up" only a cci primer and put them in the case under neck tension only. I didn't crimp them in place. |

|

|

|

Quoted:

https://www.AR15.Com/media/mediaFiles/272434/IMG_20171022_144744267-picsay-340861.JPG Got them "loaded up" only a cci primer and put them in the case under neck tension only. I didn't crimp them in place. View Quote |

|

|

|

This is a really interesting idea.

What material was used to print? Is there any concern with the friction between the bullet and barrel causing melting/fouling? |

|

|

|

Quoted:

I'm printing them in ABS, so acetone should be able to dissolve any residue left in the bore. Quoted:

Is there any concern with the friction between the bullet and barrel causing melting/fouling? Quoted:

The only advise I would have is make sure you clean the barrel with something that will dissolve the plastic your using before going back to a normal load. |

|

|

|

I wonder if one could put a gas check on them to cut down on the plastic melting from the temps.

|

|

|

|

Quoted:

Quoted:

What material was used to print? Quoted:

I'm printing them in ABS, so acetone should be able to dissolve any residue left in the bore. Quoted:

Is there any concern with the friction between the bullet and barrel causing melting/fouling? Quoted:

The only advise I would have is make sure you clean the barrel with something that will dissolve the plastic your using before going back to a normal load.

|

|

|

|

As a guy with a 3D printer, I'm interested in seeing what happens.

I can't imagine they'll hold up (though I only do PLA, not ABS) |

|

|

|

Quoted:

As a guy with a 3D printer, I'm interested in seeing what happens. I can't imagine they'll hold up (though I only do PLA, not ABS) View Quote |

|

|

|

I agree that Nylon would have been best, and I do have Nylon, but it’s expensive. Then again, none of this is not cost effective. It took just under 5 hours to print 5 from ABS at 100% infill. I uploaded the model to Shapeways to see what the cost per round would be from them, and it came at around $6 per round.

Will see how this test goes, and go from there. If the OP wants to continue I can print another set with some of the suggestions. It’s his rifle after all, and I don’t have a 50. I should have also printed them in steps from .50 to .51 in the diameter. I’m not sure if the primer only can overcome the friction at .51. The main reason I went with ABS is I know acetone will dissolve it, and I’m not sure about the rest. I wanted the OP to have a way to clean his rifle if something got stuck. EDIT: Time Laps  Time Laps: Printing 50 BMG for an AFCOMER |

|

|

|

I have plain if it isn't powerful enough to push them all the way out. I have a long 50muzzle loader cleaning rod and a dowel rod to push it back out.

My first test most likely be in the back yard into a box of tags to catch it. Hopefully I can reuse it. |

|

|

|

Quoted:

I have plain if it isn't powerful enough to push them all the way out. I have a long 50muzzle loader cleaning rod and a dowel rod to push it back out. My first test most likely be in the back yard into a box of tags to catch it. Hopefully I can reuse it. View Quote |

|

|

|

Set up this morning to try the 3d printed bullets.

Things didn't go so well, The bullet got stuck 1/2 way down the tube and had to be hammered out. |

|

|

|

|

|

I just tried to pull the rest apart by hand and ended up breaking two clean in 1/2.

I think this experiment was a failure. I was thinking about a small powder change of trail boss. But when the two snapped by light hand pressure I rethought the power. Don't want them coming apart in my fish Gill break. |

|

|

|

That bites. Do you want to try again? I can print smaller ones in nylon. Maybe at .50 with a gas check.

|

|

|

|

I was going to post this before but was waiting to see what would happen.

PC beat me to it but yeah, try using a gas check on them. Will keep them from being melted from the hot gasses. You'll also be able to use a light charge of powder. Plus you might be able to reuse them if they don't get burnt/melted from the hot gasses. |

|

|

|

I don't think reduce the size will work because they will fit to loose in the case

The way they broke by hand I doubt they would be reusable. I think they will just snap in 1/2 when they hit something. The only reason the one didn't break up in the barrel is because the barrel support the bullet 3 of them broke when I tried to pull them out of the case two snapped off by hand the 3rd I used my press to try and pull them straight up. I used vice grips to hold the bullet and it still snapped. So what is left is one good bullet and the fired one. I am not to sure about using any power I am thinking that they will snap once they leave the barrel that means it will hit the fish Gill break. I doubt it will be hard enough to damage it but not willing to take that chance |

|

|

|

So I don't know jack about Lead casting or gas checks. I take it it's a small cup that get crimped in place? Would the OP need any tools for that and have the gas check in hand?

Would I also have to make the 3D model with the groves I see lead cast bullets with? Asking cause I just don't know. |

|

|

|

Gas check is a copper cup that gets crimped on the base of the. Bullet to protect against flame cutting I would be worried that the crimping process could crack the plastic.

I have the sizing die that will also s crimp on the gas check but I don't have any 50 caliber gas checks |

|

|

|

Quoted:

Gas check is a copper cup that gets crimped on the base of the. Bullet to protect against flame cutting I would be worried that the crimping process could crack the plastic. I have the sizing die that will also s crimp on the gas check but I don't have any 50 caliber gas checks View Quote |

|

|

|

Quoted:

Maybe epoxy the gas check in place or very lightly crimp with a dab of epoxy at the base. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Gas check is a copper cup that gets crimped on the base of the. Bullet to protect against flame cutting I would be worried that the crimping process could crack the plastic. I have the sizing die that will also s crimp on the gas check but I don't have any 50 caliber gas checks |

|

|

|

If it held up to hammering it out i wouldnt worry with it coming apart at the break. Id throw 5 grains of trail boss in and go from there.

Also, i wounder how much of the bearing surface could be removed to help it only need a primer? Maybe it just needs to be shorter? Maybe something like a wooden dowel would make a better bullet. I know there have been wood bullets used in the past for trainers. Just spitballing here |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.