I came to the realization that I needed a solid rest to shoot from when hunting coyotes. I started thinking about shooting sticks, but I wasn't very impressed by what I saw available in my local stores. I'm not by any means cheap, but I hate paying for products that don't fully suit my needs, when I can build something at home to my own specs for much less. I decided to build my own......

First off, I took my hunting methods into consideration before selecting materials:

-I'm hunting coyotes in a rural midwestern area.

-I'm hunting timber, pastures, and open fields near CRP acres.

-I'll be hunting mostly from a seated or kneeling position.

-I'll be using these to hunt at night, as well as during the day.

-I'll be using the shooting sticks to support a 16" AR-15 mid-length or a lighter .22 rifle.

So I decided I needed to meet the following criteria:

-light-weight

-thin, yet strong legs

-tripod-design for maximum stability and adaptability

-material that will not generate excessive noise

-adjustable for support-height

I also got very lucky, Craig Boddington had written a very good article on the subject that covered some of the more subtle areas of using shooting sticks. I adapted his thoughts and methods to my own design criteria.

http://www.sportsafield.com/FAQ/Africanshootingsticks.htm

Next, I went shopping at my local farm/home store for materials, where I came across some driveway markers similar to these:

driveway markers

The markers were perfect for the legs, with a 1/4" fiberglass shaft, roughly 48" long, and less than $4 each. Strong, light-weight, and relatively quiet compared to wood/metals. I bought three, and proceeded home to get to work.

First off, I used a tubing-cutter to score a cut-line in the shafts, which I actually cut with a hack-saw. I eye-balled the height based off a sitting position, which came out to roughly 39" in length. That is coincidentally waist-high for me, so that might make a good reference point for cutting lengths.

Next, I used a bench-grinder to shape the shafts into a shallow stake-point on one end, then gently rounded the other ends on the wire-wheel.

Up next is painting. First, I striped the shafts with some flat-black and gray auto primer. Next up, I used a razor blade to cut some random patterns in a roll of blue painter's tape, which I then peeled and applied to the black/gray paint on the shafts to establish a bit of a tiger-stripe.

Next up, I started working with earth-tone paints to create my camo. I selected colors based off the local terrain, earth-brown, flat green, and straw. I proceeded to spray the shafts with a general base layer, which I will work over later to help blend the tones. I sprayed the lower third in brown, the middle with green, then the tops with straw. We can start with the pictures now:

Here, you can see the masked areas as I build up the layers:

Once the base layers are established, we can mix in the different colors in stripes to break up the pattern:

This pattern is turning out very well, since it's getting difficult to see the sticks against the background at short distances. I found that if your paint-job looks poor up close, it looks great at a distance. Remember, over-spray is your friend when it comes to camo.

Next up, we'll peel off the tape to see how everything turned out:

Again, blends right in......

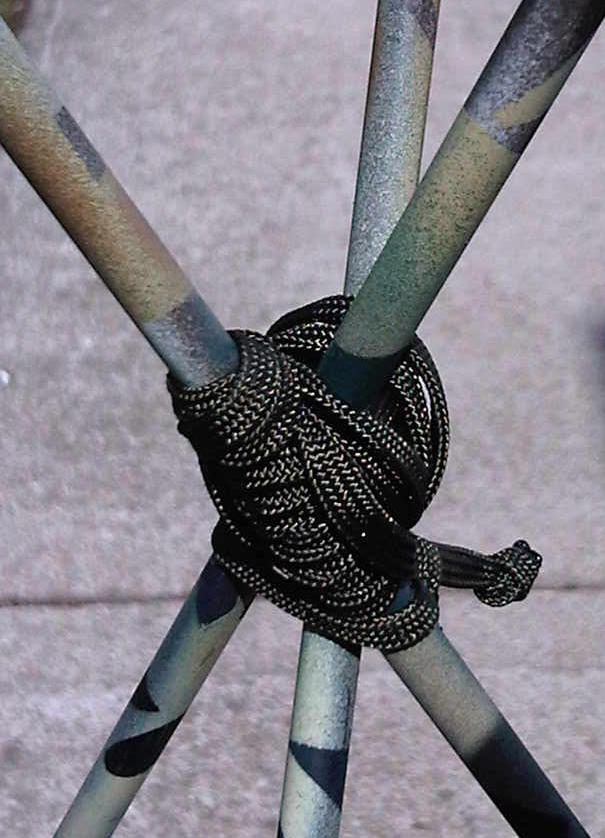

Next, I started lashing everything together. I used 550 cord with the inner-strands stripped-out for my project for resistance to the elements. I found a very good visual reference for the lashing method here:

Tripod lashing

And here's how it turned out:

I also tied-up a small noose slider to serve as a binder for the lower sections, to keep them from rattling and flopping around:

I was concerned the tripod would be a little wobbly due to the thin material, but it turned out to be surprisingly strong. Here's the finished product:

To adjust the height of the rest, collapse the legs and slide the shafts through the knot individually, one at a time. There should be a little slack in the knot when the rods are collapsed. To keep the 550 cord secured, melt the cut ends with flame to keep everything from unraveling. I also knotted my tag ends securely to keep the knots from working loose.

Improvements I'm considering are to superglue/epoxy some small felt strips to the bottoms of the legs to act as scent-wicks for masking scent products. A person could also attach felt or foam rubber to the top of the structure to act as a cushion to keep contact-noise to a minimum, and to keep from marring the finish on wood stocks.

I did not use rubber inner-tube sections for the lashing, as rubber does not stand-up well to the elements over time. It is an option, however.

This design could also be easily used as a bipod, monopod, or emergency splint in the field. I like adaptability.

Win a FREE Membership!

Win a FREE Membership!