Well, the set screw for the extractor is good, but the threads in the extractor are gone I guess. They were gone from the beginning, only thing keeping the set screw in there was blind luck.

I used the gentlest bit of blue loc-tite to keep the set screw in place until I can get it under a magnifying glass and identify what the problem is exactly. If need be, I'll send the extractor and screw to Zoli USA and let them fix it. I've fixed hundred of threads in my work at various engine and cylinder head shops, but nothing this intricate.

I thought I could get away scot free, but I could not.

Clean Breech Face

Clean chamber face, chamber and barrels

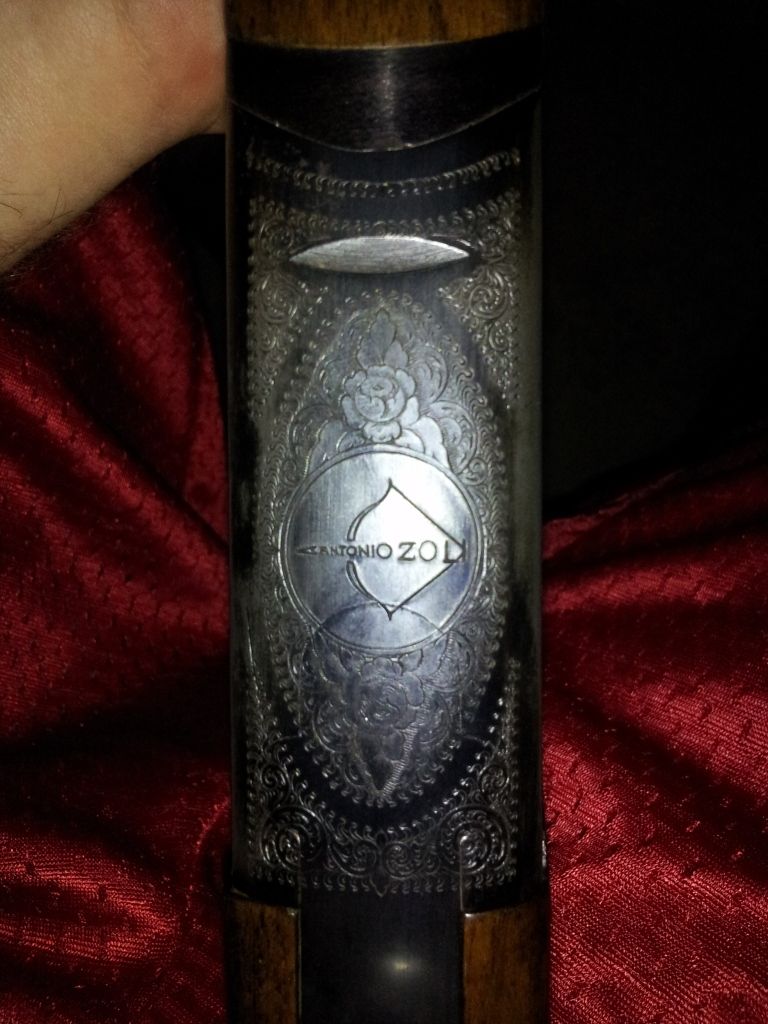

Zoli Logo. You can see the fairly nice machined fitment between parts. The bluing is coming off from time and use, but I'll be keeping a light coat of oil on it from now on.

Scroll work. I do not know if it was cast, stamped, or done by hand.

A little history. Antonio Zoli USA has no idea what this shotgun is. Antonio Zoli Italy has been even less help, mostly due to the language barrier.

This particular shotgun is a Model 281.51266 20 ga. 3"Mag

My old man purchased it new from Sears and Roebuck in the early to mid 70's for $120, he doesn't remember. I'm in contact with Zoli to get a build date. This shotgun in current condition is worth around $400, and in my limited opinion would be a great buy at that price.

This is the last email I got from Zoli USA:

Sweptvolume,

It looks 60's. Has the desirable top lock- very strong. Engraving is probably hand finished. It was competing with b25 browning. Good gun with hand fitting. Many of these guns were made for abercrombie and fitch.

Srl

stephen r. lamboy

president

antonio zoli na

recreation dr.

canandaigua, ny 14424

585 590 1024

The story I get through the grapevine is that S&R imported these guns and Zoli sold them at a slight loss to enter the American market. The fit and finish on the metal parts is fine, the locking lug sits proud of the action body slightly, but the rest of the joints are flush. The wood had received less attention than the metal in manufacturing, and it shows. It's finished well, but doesn't lay flush on the sides.

New Zolis are nicer. The entry levels are mid-line shotguns. Around $3,000 for a base model. I think my next Fudd shotgun will be a Beretta.

This shotgun has killed teal, quail, snakes, skunks, armadillos, and ducks. My Gen 1 Nova is my go-to gun for turkeys, ducks, geese, and home intruders, but I fell in love with this little shotgun years ago and my dad gave it to me. It points like a finger and is light enough to hold on to all day long.

Win a FREE Membership!

Win a FREE Membership!