|

Posted: 5/3/2010 4:56:46 PM EDT

Hey Guys,

Dawg180 got me to thinking about his thread on the prototype slip ring and I was wondering if anyone is making a prototype front sight block like the ArmaLite sn000002 and 000003 guns that are on pgs.67-69 of The Black Rifle? I have three in the white barrels from the Century M16A1 kits and I thought how cool could it be to have a FSB like the two prototypes in the Black Rifle book mounted to those barrels. If no one is making anything like that, how hard would it be to have one made? I have a friend who is a Machine Shop Teacher and a gun enthusiast, that I thought I might talk to about possibly making one to see how it would work out. What say the hive? 04ZREX |

|

|

|

This is exactly what early prototype/AR-10 wannabe's like myself would love to see. With undrilled A1 profile barrels becoming available the time is ripe.

|

|

|

|

That's exactly what my thoughts were on this matter, as I want to build something as close to the real prototypes as possible and still be able to shoot modern ammo with these 1/9 twist barrels on the market right now.

|

|

|

|

I believe there was a guy on here who's girlfriends cousin's uncle was working on a couple of those, but I don't recall who it was now. Maybe he'll come along soon.

|

|

|

|

I am also searching for such an item. I hope someone takes this project on. 04ZREX if your friend makes one, see if he'll make two, because I really want one!

Also, does anyone have some pictures of those early rifles they can post? I've seen pictures in books, but I can't find very many good pictures of them on the internet? Thanks! John Thomas |

|

|

|

I noticed there is a really good picture on page 59 of the Black Rifle Book as well. I'm assuming that casting would be too expensive, so machining a piece of steel would be the way to go I assume. What type of metal would be best for this type of application?

|

|

|

|

|

|

Quoted:

I believe there was a guy on here who's girlfriends cousin's uncle was working on a couple of those, but I don't recall who it was now. Maybe he'll come along soon. Ach so.

|

|

|

|

|

|

Quoted:

Is there a lathe-meister out there that would be willing to make a pair of real ones? The photo below is what the AR10-portuguese slip ring looks like after being beat up in the field. It has 24 tpi inside and is beveled. I could sure use a nice pair. http://i42.tinypic.com/fp251.jpg If I had an original in my hand I'd sure be willing to take a stab at reproducing some of those slip rings for you. Shoot me an IM. |

|

|

|

PrivateSnafu, Thanks for the photos, I'm going to show them to my friend and see what he says about making some.

|

|

|

|

|

|

I'd love a prototype FSB.

If someone takes on the project, give me a shout! |

|

|

|

Is anybody serious about making some of these? I'd consider it, but I don't want to step on anybody else's ambitions.

|

|

|

|

Quoted:

Is anybody serious about making some of these? I'd consider it, but I don't want to step on anybody else's ambitions. I've been searching for one of these for a long time and asked several people if they would consider making one for sale, but I have not had any luck. If you take on this project, please put me on your list of buyers. John Thomas [email protected] |

|

|

|

Hey guys I did start doing some research on casting methods and came to the conclusion that machining is probably the way to go. I'm still trying to find someone who will take on this project as I'm not a machinist nor do I have access to such equipment. If someone else here has the skill set and equipment, please chime in. Until then, I will continue my search for such a person. I really want one of these for my prototype build.

|

|

|

|

I'm still trying to find someone who will take on this project

So, I take it your friend said it was a no-go? Thanks, John Thomas |

|

|

|

He's not interested,

|

|

|

|

Well I do have the connections because of my real job, and I've had some requests; so I'll start taking a closer look at the project.

|

|

|

|

Quoted:

Well I do have the connections because of my real job, and I've had some requests; so I'll start taking a closer look at the project. YAY! |

|

|

|

Quoted:

Well I do have the connections because of my real job, and I've had some requests; so I'll start taking a closer look at the project. I'd sure be interested in one, and maybe some barrel work to go along with it. |

|

|

|

If HeatNBeat takes this project you know is gonna be outstanding as is all his other work.

|

|

|

|

Does anybody have any good pictures of the version with the bipod mount on the front? I'd also be interested in any and all pictures; anything that will help me model these .

Thanks Guys! |

|

|

|

Quoted:

Does anybody have any good pictures of the version with the bipod mount on the front? I'd also be interested in any and all pictures; anything that will help me model these . Thanks Guys! Here some ideas from retro AR10s (courtesy of Buddy Hinton's website). Good luck with your project, please put me on your list of buyers. Thanks, John Thomas [email protected]

|

|

|

|

Quoted:

Does anybody have any good pictures of the version with the bipod mount on the front? I'd also be interested in any and all pictures; anything that will help me model these . Thanks Guys! Hey Jerrell, Very detail pics here: http://www.ar10.nl/Welcomepage2.htm *someone heat it up for us please. |

|

|

|

|

|

Along with my interest in RBRs I also have an interest in 18th century French military muskets. One of the firms making parts for these muskets is The Rifle Shoppe, 18420 E. Hefner Road, Jones, Oklahoma 73049, Phone: 405-396-2583, Fax: 405-396-8450, [email protected].

The Rifle Shoppe produces castings in 4140 steel using original parts. They usually get the original parts from collectors or others interesting in reproducing a particular part. I believe I read on one of the muzzleloading boards that The Rifle Shoppe requires a minimum order of only 10 items before they make a run of a particular casting. They may be interested in casting an AR 15 prototype FSB if someone would make a pattern. I suspect that the pattern could be made from a standard FSB and with some judicious use of epoxy and bits of metal and/or plastic. The Rifle Shoppe is a very small organization and they sometimes have long lead times but the parts I have received from them have been outstanding. Just a thought. |

|

|

|

Thanks for thelead on the Rifle Shoppe. I have one place giving me a rough estimate at the moment, and I'll check with them. Making the model isn't a problem as I work in a design and development shop ( when I can get out of mine LOL). All I really need is some decent pictures

|

|

|

|

I was just looking at the link I sighted earlier. Really good pics there. If you scroll down there are Hi-Res pics of individual components. I am so down for these if we can get them going.

|

|

|

|

I just wanted to bring this thread back to life. I have accumulated a lot of special parts for a project I've been working on for a long time, and I really "need" one of these front sight bases. Has anyone gotten anywhere with this idea?

Thanks, John Thomas |

|

|

|

I'm thinking one of these would look great on a middy pencil barrel with an NDS-32 upper.

Oh well the wife can only kill me once..... Put me on the list also please. |

|

|

|

Quoted: I don't too much care for carbines, but damn! "Hot, sweet n' sexy" doesn't even come close to describing that thing. |

|

|

|

Quoted:

Along with my interest in RBRs I also have an interest in 18th century French military muskets. One of the firms making parts for these muskets is The Rifle Shoppe, 18420 E. Hefner Road, Jones, Oklahoma 73049, Phone: 405-396-2583, Fax: 405-396-8450, [email protected]. The Rifle Shoppe produces castings in 4140 steel using original parts. They usually get the original parts from collectors or others interesting in reproducing a particular part. I believe I read on one of the muzzleloading boards that The Rifle Shoppe requires a minimum order of only 10 items before they make a run of a particular casting. They may be interested in casting an AR 15 prototype FSB if someone would make a pattern. I suspect that the pattern could be made from a standard FSB and with some judicious use of epoxy and bits of metal and/or plastic. The Rifle Shoppe is a very small organization and they sometimes have long lead times but the parts I have received from them have been outstanding. Just a thought. Okay guys here is the latest from my end on this project. I actually live about 45 minutes from "The Rifle Shoppe" in Jones, Oklahoma. I called the owner "Jess" and talked to him this morning. I explained to him what we were looking for on this project and he said that he had produced some FSB's for some others guys with AR's, so I'm going to go look at what kind of work he does. I going to take along some of the photos that you guys have provided along with a standard AR FSB. He said that he can do temporary molds for single items and permanent one's for several castings. What all do you guys want me to ask about and/or show him? Remember, I'm not a gunsmith or a machinist so any help would be great. I just know that I want one of these prototype FSB for one of my projects as many of you have indicated as well. I plan to use one of the in the white pencil barrels that Century is producing. I would like to send the parts to Heatnbeat for assembly and refinishing, so please chim in on this one Heatnbeat as to what you would like to know about this guys work. Thanks |

|

|

|

Oh, for you technically literate AR buffs, does anyone know what metal the AR FSB's are made from? I want to get something as close to the original as possible, and I don't want something produced that will not withstand the pressure required by the AR's gas system. Someone please educate me before I meet with Jess at The Gun Shoppe.

Thanks |

|

|

|

|

|

Quoted:

Quoted:

Along with my interest in RBRs I also have an interest in 18th century French military muskets. One of the firms making parts for these muskets is The Rifle Shoppe, 18420 E. Hefner Road, Jones, Oklahoma 73049, Phone: 405-396-2583, Fax: 405-396-8450, [email protected]. The Rifle Shoppe produces castings in 4140 steel using original parts. They usually get the original parts from collectors or others interesting in reproducing a particular part. I believe I read on one of the muzzleloading boards that The Rifle Shoppe requires a minimum order of only 10 items before they make a run of a particular casting. They may be interested in casting an AR 15 prototype FSB if someone would make a pattern. I suspect that the pattern could be made from a standard FSB and with some judicious use of epoxy and bits of metal and/or plastic. The Rifle Shoppe is a very small organization and they sometimes have long lead times but the parts I have received from them have been outstanding. Just a thought. Okay guys here is the latest from my end on this project. I actually live about 45 minutes from "The Rifle Shoppe" in Jones, Oklahoma. I called the owner "Jess" and talked to him this morning. I explained to him what we were looking for on this project and he said that he had produced some FSB's for some others guys with AR's, so I'm going to go look at what kind of work he does. I going to take along some of the photos that you guys have provided along with a standard AR FSB. He said that he can do temporary molds for single items and permanent one's for several castings. What all do you guys want me to ask about and/or show him? Remember, I'm not a gunsmith or a machinist so any help would be great. I just know that I want one of these prototype FSB for one of my projects as many of you have indicated as well. I plan to use one of the in the white pencil barrels that Century is producing. I would like to send the parts to Heatnbeat for assembly and refinishing, so please chim in on this one Heatnbeat as to what you would like to know about this guys work. Thanks Would they be made for .625 diameter barrels? Dustin |

|

|

|

which model are you thinking of having reproduced? Some models are simpler than others.

as far as the material used, I know there are some aluminum gas blocks out there that don't seem to be having a problem with handling the heat and pressure of the gas system, so I would think if he uses any type of steel at all, it should be OK....but I'm not a metallurgist, so I may be talkin' out of my posterior here

|

|

|

|

Quoted:

I want to get something as close to the original as possible, and I don't want something produced that will not withstand the pressure required by the AR's gas system. Someone please educate me before I meet with Jess at The Gun Shoppe. Thanks Additionaly, some of my recommendations for your consideration are: 1. Have the hole set up for the .625 barrel. If someone wants to use a heavier barrel, they can bore the hole larger; however, those using the .625 barrel can't (easily) make an oversized hole smaller. 2. I'd suggest not drilling the mounting pin holes (just like the current front sight bases when they are new). This drilling should be done as part of the installation. 3. If casting the "UP" and "arrow marking" significanty raises the price, I would forego that option. If the cost is minimal, I'd go with it. 4. Ensure it's dimensions accomodate a standard gas tube (don't require shortening the gas tube). 5. This is getting into the weeds, but maybe leave them in the white instead of parkerizing. This way, we can finish them to match our needs, plus the finish may get marked up during installation. I really appreciate you taking this on 04ZREX. I was concerned the project was dead, Thanks very much. John Thomas [email protected] |

|

|

|

Quoted:

http://www.hunt101.com/data/500/35327armalite-tch.jpg Is this FSB the same as the one on the first page, only with a bayonet attachment? I think I would be interested in one. Dustin the bayo lug is actually part of the flash hider not the fsb on an Ar10 |

|

|

|

Will you put the gas port hole and gas tube roll pin hole in the standard location so that a normal gas tube can be used? Standard sling swivel slot and roll pin hole size as well?

Dustin |

|

|

|

Quoted:

Someone please correct me if I'm wrong, but I was under the impression that the ring or what ever it's called in front of the FSB on the following picture, is for mounting a bipod on the prototype, not for a bayonet. Or is it part of the FSB? http://i409.photobucket.com/albums/pp179/04ZREX/35327armalite-tch.jpg That was my question as well. My best guess is that it can be made as a seperate part and installed in front of the FSB if wanted. Dustin |

|

|

|

Quoted:

Someone please correct me if I'm wrong, but I was under the impression that the ring or what ever it's called in front of the FSB on the following picture, is for mounting a bipod on the prototype, not for a bayonet. Or is it part of the FSB? I'm pretty sure you are right... that is a provision for a bipod. I do not think that is part of the front sight base, based on what is evident on the AR10. EDIT: I stand corrected, the bipod mount is part of the sight base. My apologies for any corrections. John Thomas [email protected] |

|

|

|

Quoted:

Will you put the gas port hole and gas tube roll pin hole in the standard location so that a normal gas tube can be used? Standard sling swivel slot and roll pin hole size as well? Dustin That's what I'm thinking, so we could use a standard model gas tube and pin. This is why I'm planning on taking a FSB from one of my Colt M16A1 parts kits to the meeting with Jess. This would allow a carbine or rifle gas tube to be used depending on what barrel you use. |

|

|

|

|

|

Quoted:

Quoted:

Someone please correct me if I'm wrong, but I was under the impression that the ring or what ever it's called in front of the FSB on the following picture, is for mounting a bipod on the prototype, not for a bayonet. Or is it part of the FSB? I'm pretty sure you are right... that is a provision for a bipod. I do not think that is part of the front sight base, based on what is evident on the AR10. John Thomas [email protected]

|

|

|

|

Quoted:

Quoted:

Quoted:

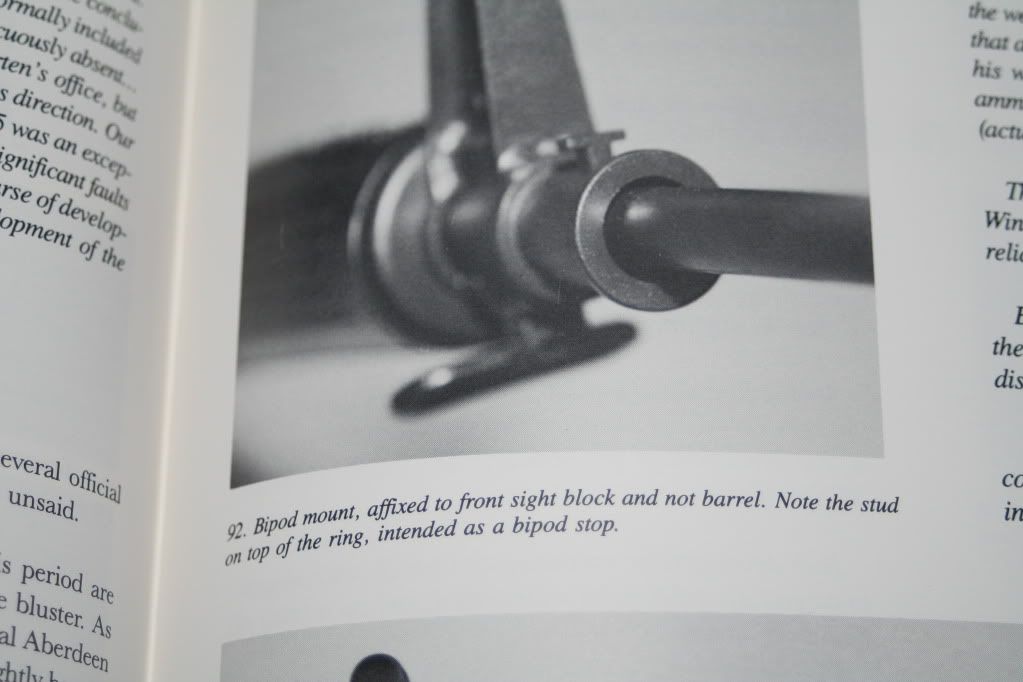

Someone please correct me if I'm wrong, but I was under the impression that the ring or what ever it's called in front of the FSB on the following picture, is for mounting a bipod on the prototype, not for a bayonet. Or is it part of the FSB? I'm pretty sure you are right... that is a provision for a bipod. I do not think that is part of the front sight base, based on what is evident on the AR10. John Thomas [email protected] http://i151.photobucket.com/albums/s147/crackedcornish/351e4acc.jpg Ok, so "The Black Rifle" book says the following "Bipod mount, affixed to front sight block and not barrel. Note the stud on the top of the ring, intented as a bipod stop." How in the world does the bipod mount affix to the front sight block and not the barrel? Is this something else I should consider while talking to Jess about making the FSB? I would have thought that it attached to the barrel with something like a set screw or something like that, but remember I'm not a gunsmith, so I claim ignorance on this part. Is the bipod mount a cast part as well? |

|

|

|

Quoted:

Now, I know that Boywonder777 is working on a prototype A buttstock with the pegasus logo on the buttpad, so who is going to develop round prototype hand guards for us sick soles seeking to build a prototype clone. I'm going to talk to a guy who is making injection molded pistol grips for the AK community, about possibly making something for us that mimicks the prototype pistol grip, since he can come up with custom colors with his dyes. If the custom molding doesn't pan out, or for another option, I can do the brown mottled finish for those interested. Email me on the side for details. John Thomas [email protected] |

|

|

|

http://i151.photobucket.com/albums/s147/crackedcornish/351e4acc.jpg "Note the stud on the top of the ring, intented as a bipod stop." How in the world does the bipod mount affix to the front sight block and not the barrel? I wonder if the intent was to use a "clothes pin" type bipod, like the common Colt type accessory bipod. It could clip on the mounting provision and the prong that sticks up would preclude it from spinning 360 degrees around the barrel. ??? John Thomas |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.