Quoted:

Brothers and Sisters, I know nothing about these guns. I'm an old guy with a small gun safe full of shotguns and lever guns that I've been collecting for my 11 year old son, I'm in California (I'm sorry too)

It seems every gun person I talk to tells me get him a lower in the safe...

I can get a complete New Frontier ploymer lower for 200.00 ..I'm also thinking about getting an anodized 80% lower from a local company (80percentarms) for 180.00 and making it 100% as soon as I get it. I'm stuck on what to do. We don't shoot much but I'd like him to have a good gun. I'm asking what's best and not worried too much about how much its going to cost. I figure we can do this slow...

For now,these are my options...what do yo think?

Hello Goldfish -

Saturday I finished my 80% lower from 80percentarns. I did it all in my garage with only a drill press. I'd be glad to give you any tips if you decide to make your own AR. This was the first 80% lower I did by hand. It was smooth sailing. Below are some pics from start to finish. I also used the 80percentarms jig. The biggest problem was the earful I got from my wife when I tracked into the house aluminum shavings into the carpet!

Took a good part of Saturday to do it but it was not hard to do.

Basically I wanted to build an AR that I did not have to register, that was modestly priced, and reliable. I had all the parts for about a month now except the upper. The upper arrived Tuesady and now my newest baby is finished. Still waiting on optics to arrive but other that that she's pretty much ready for duty!

Total cost was $1,527 for a good quality AR. I saw a lot of no name junk at the gun shows lately going for $2,000+ so the price was not too bad despite today's high parts prices.

The fit was perfect. There is no wobble or rattles anywhere. The CTR stock has a latch to take up slack so everything is rattle free. I know wobble is functionally fine on an AR but on my Noveske it always bothered me the amount of wobble between the upped and lower and the fact the stock also rattled. I don't like the idea of putting something foreign in the lower such as the wedge so I was very happy with the fit of the 80% lower.

Here is a list of the tools I used:

Drill press Craftsman 12"

80% Arms AR-15 jig

1/8" drill to drill pilot holes

3/8" drill for selector switch pin hole and to drill out material from pocket area

5/32" drill for trigger and hammer pin holes

7/16" drill to drill through lower for trigger slot

1/4" end mill bit

3/8" end mill bit

Quicke release c-clamps (2)

Gear purchased and cost:

ALG QMS trigger - algdefense $45 No creep, very crisp

80% lower black anodized - 80percentarms $171 and free shipping with coupon code rfr1837

CMMG Lower parts kit - riflegear $85

Spikes buffer tube kit - eBay $90

Magpul CTR stock $75 - OC gun show

Unk brand bipod foregrip - Bargained down to $25 at gun show

BCM Standard 16" Mid Length Upper Receiver Group w/ VTAC ALPHA 13" Handguard bravocompanyusa $949

Magpul MBUS Gen 2 front & rear sights $87Amazon

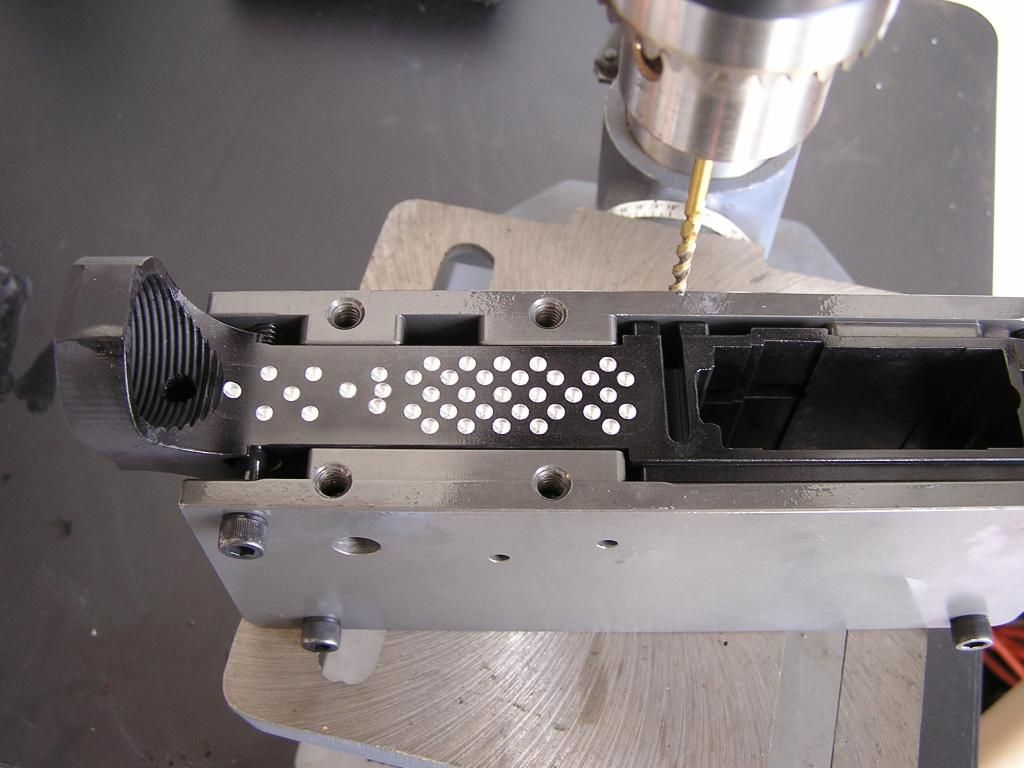

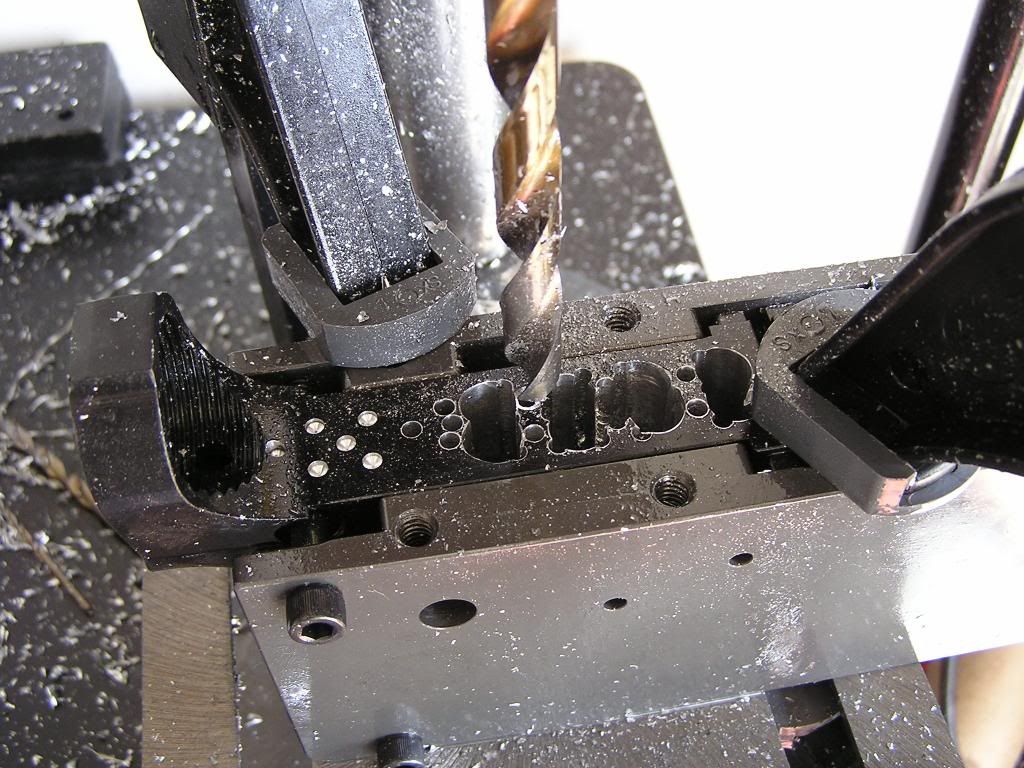

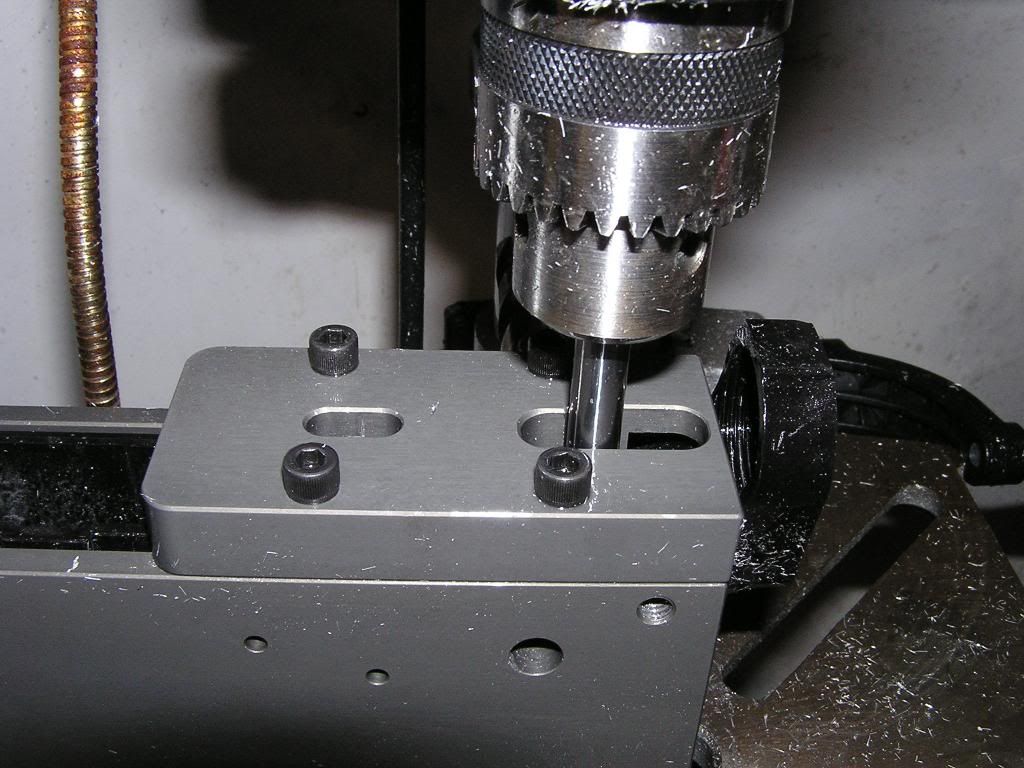

In the trigger pocket area I drilled down just under 1.25" and used the drills to remove the bulk of material. Then I used the 3/8" end mill to clean it all up down to 1.25". For the rear shelf drilled to just under 0.63" then used 3/8" end mill down to 0.63" to clean it up. Drilled 7/16" hole through lower and then used the 1/4" end mill through the 7/16" hole to make the trigger slot. Was very easy with the guide plates included in the jig set. I had the drill press speed set to 880 RPM .

Finished product:

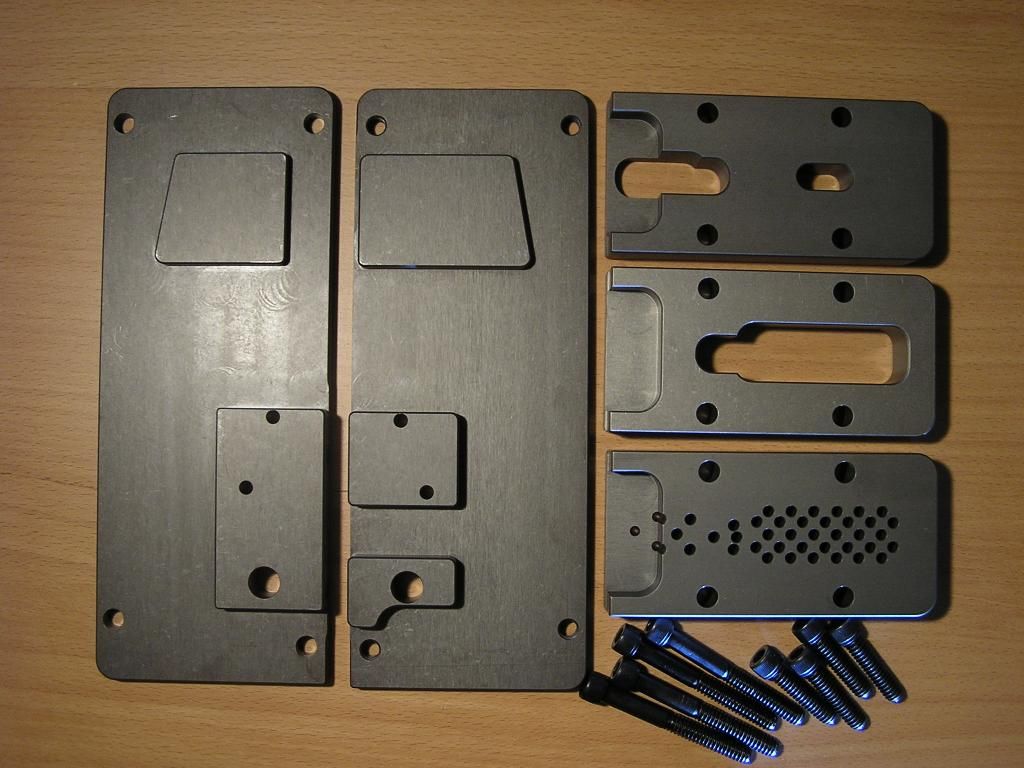

Jig:

80% Arms lower:

Making pilot holes:

Drilling out excess material:

Using jig template to mill out lower:

Milled out and completed lower:

Perfect fit:

Win a FREE Membership!

Win a FREE Membership!