I thought I’d give everyone a little review on my experiences with CNC Warrior and their receivers since there are still many people asking about them and there still isn’t very much info about the receivers themselves.

About six months ago I placed an order with CNC Warrior for one of their milled, fixed stock, Russian pattern, threaded barrel receivers and a new cover plate for the receiver. I planned on using this receiver for my Chinese milled spiker that I’ve always wanted but was too chicken to perform on my Legend. About four months went by with no word from CNC Warrior about the status of the receiver. Granted, I never asked about a status since their website had already stated that they will wait for at least fifty pre-orders until they even begin the manufacturing process. Then, one day I get an email stating that they are ready to begin production and that they will need a copy of my FFL, credit card info, list of what I wanted done, and my receiver stub or barrel. The receiver stub/barrel are need not only to replicate the thread pitch, but also to match the thread timing so that the original barrel that one may have from a kit should time correctly to the new receiver.

In addition to the standard options that were listed on their site (which have now been replaced with two “package” options instead of individual ones) I had requested that they cut a side sling swivel in the left side of the receiver, fit the new cover plate to the receiver, and rivet the trigger guard to the receiver. All of their gunsmithing operations are carried out by an outfit called CMP Armory (not to be confused with the government CMP), and they are the ones who do all of the rivets/fitting of parts. About a month later I received another email stating that my receiver was ready to go and that they would be charging my card the following business day. In that same email was my tracking number for the package, which I appreciated. Here is a copy of the invoice so you can get an idea of what the different options run:

Threaded Receiver, Russian Fixed Stock (minus 26.28 deposit) - $323.71

Bullet Guide Cover Plate - $4.99

Selector Stop (provided and installed) - $20

Bullet Guide (provided and installed) - $15

Lower Tang (provided and installed) - $15

Pistol Grip Nut (provided and installed) - $15

Sling Swivel Cut (left hand side) - $15

Trigger Guard (installation only) - $20

Shipping and Handling - $15

Total - $428.70

As you can see I decided not to go with any type of finish or selector notches since CNC Warrior’s notches are more like dimples. They don’t match any type of selector notch that I’ve seen. Also, I plan to have the receiver engraved with the original Chinese markings by Mario at PoH and do the selector notches which will require a refinish anyway so it made no sense to pay for a finish.

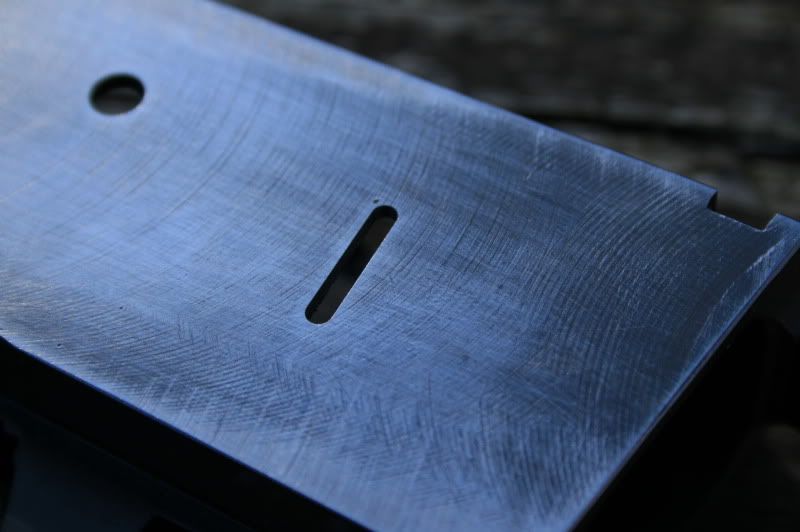

The receiver and barrel were shipped via UPS 3-Day Select and much to my surprise, arrived a whole day early. The receiver and barrel were wrapped in heavy butcher paper and were padded by a ton of newspaper. The first thing that I noticed was the fairly rough looking machining on the receiver flats. The next thing, however, was how the lightening cuts resembled that of my Polytech Legend in terms of the grain and shape, which of course is perfect for this build. My dealer happened to notice a small dip in the right hand side of the receiver that resembled some kind of pin that had been installed, but turned out someone at CNC Warrior got a little heavy handed with a grinder of some sort. Not something that inspires confidence or cheerfulness when it comes to how much cash I dropped on this thing.

This is the point where there’s a dip in the receiver, which is hard to see in the pictures, but is easily seen in person and is even more noticeable when felt:

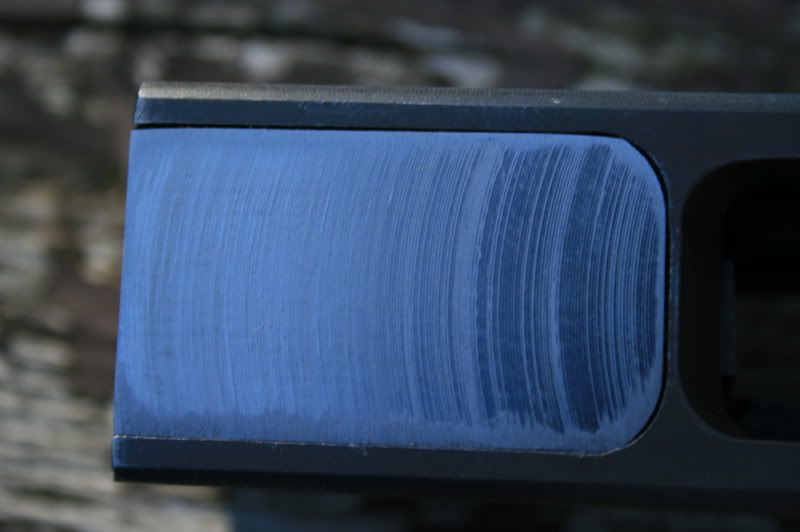

The threads for the barrel are well executed in my opinion, and the barrel hand times slightly short of the ideal 15 degrees of top dead center. This is where sending in your stub/barrel pays off, because having to add breeching washers to correct over timing, or even worse, having to machine the barrel to correct under timing, would be a total PITA.

Here is where I start to get a bit disappointed, and it’s with CMP Armory. The riveting of the bullet guide and lower tang are acceptable, but the riveting of the trigger guard is flat out fugly. At the time of sending in the barrel and trigger guard to CNC Warrior I had no means of riveting a trigger guard myself. But during the wait for the receiver I was able to pick up a nice riveting jig and practiced on a few receivers where the heads of the rivets looked almost factory. These, however, speak for themselves:

The rivet in the lower tang came with a fairly nasty split in it, but I doubt that it will cause any real problems:

Here are the bullet guide and lower tang, which as I said, are acceptable to me:

I’m truly happy that they didn’t charge me for the “fitting” of the new cover plate because so far used surplus cover plates that have already been installed on other rifles have better fit and finish than this:

At this point I think I may have been better off ordering a receiver from Firing Line and paying that extra coin that they demand. But only time will tell. Well that’s it for now. I’ll update this thread as I continue the build and I’ll document any problems that I encounter. If anyone has any questions or comments just post them!

UPDATES:

1/2/2011

The FCG went in without any hiccups and can be operated freely and smoothly. The selector lever also went in easily and operates smoothly. The Bolt carrier sticks right in the middle of the receiver rails even without any internals installed, which requires a brisk tap with the palm of the hand to free. Upon inspection I noticed no burrs or other obstructions in the receiver or the bolt carrier. I went ahead and applied some 600 grit lapping compound to the carrier and ran it back an forth until I obtained smooth operation.

I tried many different magazine from different countries in the receiver and they all fit very well with a strong and easy lockup. The pistol grip fit with no issues and the buttstock only required minor fitting. Hand tightening the barrel shows that there should still be plenty of clearance before the barrel hits the stop inside of the receiver when fully tightened.

Win a FREE Membership!

Win a FREE Membership!