| you could also do a muzzle device like the OPS brake to act as a primary blast baffle. this would take some of the punishment off of the blast baffle, and be easily replaced, rather than a welded part inside of your can. just a thought. |

Bingo... the middle index threads on the rear of a Brake, the rear index wedges onto a contoured barrel, and the front index fits around the crown of the brake.

| Don't use any aluminum for 223. it will not survive. Typically, the blast baffle is Inconel or similiar as even stainless will look like a bad bead blasting job after a while. Remaining baffles should be stainless. Since you're using a two point mount, check out some of the Finnish designs as they're much simpler on the back end and that volume can be put to good use. |

Turning inconel on a benchtop lathe might be near impossible. Heck, I'm just hoping it handles 304 Stainless easily.

The can will have a stainless blast baffle and a a muzzle brake to take the hardest beating.

You don't think 3 Aluminum baffles would fair well sitting behind a brake and blast baffle in a stainless tube?

Doesn't the Tac 16 have aluminum baffles?

Would

Titanium be a better choice?

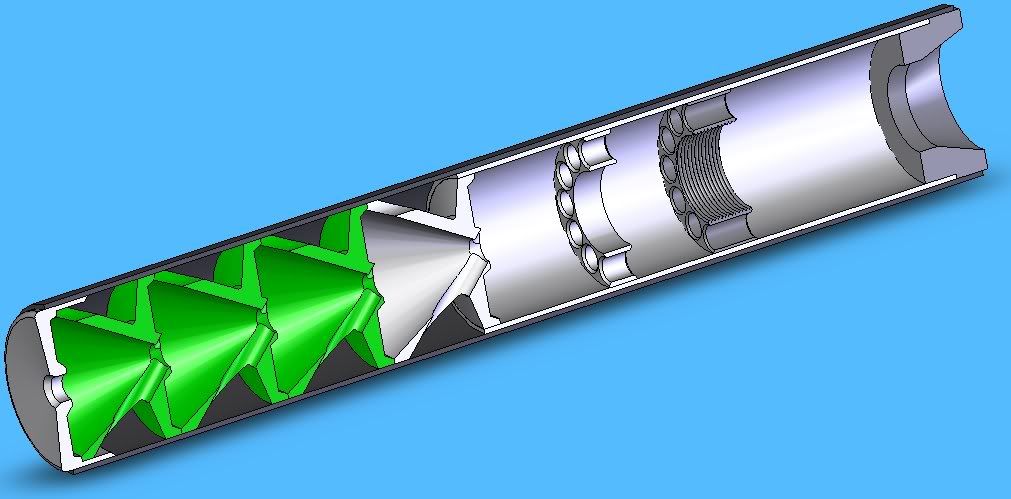

Anyways, the design below is a tad bit lighter. It gets rid of the double tube and uses a stepped tube with a double tube around the blast chamber. It also lightens up the baffles a little.

The blast chamber tube is .050" and the outer tube is .065" - both made out of Stainless as well as the blast baffle, and both endcaps. This way the suppressor can be welded shut.

The blast chamber parts will all be fully welded and the endcaps will be welded onto the outer tube. K-baffles 2/3/4 will be aluminum.

OAL Length is 10.5" and Diameter is 1.750" with 6.25" length added to the host weapon.

If construction is 100% 304 Stainless the weight is 40oz.

If baffles 2/3/4 are aluminum 33oz.

For a 10.5" x 1.75" can I think 33oz-40oz is about as light as it's gonna get...

I mean, a proportionally weighted/sized AAC M4-1000 would weight about 30oz and this is just a form 1 can.

Win a FREE Membership!

Win a FREE Membership!