Lately I've seen a lot of new reloaders having problems resizing their bottleneck rifle cases and getting them to fit their rifles. Following the die makers instructions often results in over-sizing, which shortens case life.

The ideal set-up is to bump the shoulder back as little as possible, but how do you do that and how would you measure it ?

We could all buy a comparator that fits onto our caliper jaws, but for those of us who may not have the cash to buy the attachment and all the bushings for the various calibers we reload, I thought I would show everyone what I did to make my own.

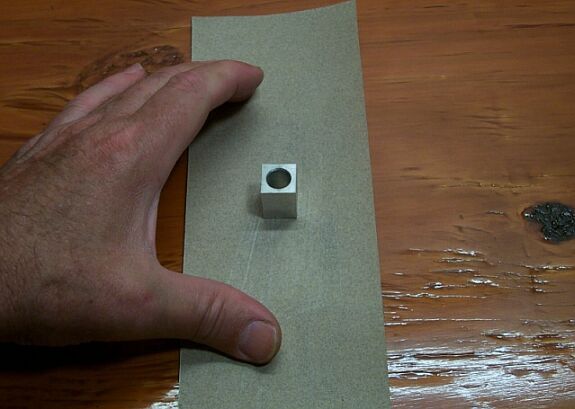

First, here's a pic of what I'm talking about.

" />

I made this one for .223 a few years ago.

I found a piece of half inch aluminum round stock and cut it about 3/4'' long, drilled a 19/64 hole in it, sanded the ends so they were square, lightly chamfered/deburred one end inside the hole and put a heavy chamfer on the other. Put it on a fired case, took a measurement, sized it and took another measurement. There was a .003'' difference, which meant I was setting the shoulder back that much +/- .001''.

So, it looked like my homemade comparator worked. Plus, it was easy to spot check a few here and there during a session.

About a year ago I started reloading .308 Rem and needed another comparator. Here’s a more detailed explaination of how to make that one. The same thing applies to .223 except the hole is smaller.

I found a piece of 3/4’’ aluminum square stock, cut it about 1’’ length, drilled a 25/64 hole in the center lengthwise. The hole doesn’t have to be exactly in the center, a little off is OK.

A 25/64 drill bit puts the hole in the middle of the shoulder, the datum line.

I put a sheet of 80 grit sandpaper on a flat surface and moved the part back and forth on both ends. I checked it for square using calipers. If it didn’t sit straight in the jaws or moved around I sanded more where it needed it. When it fit in the jaws without moving I used 120 grit then 220 sandpaper, still checking for square with the calipers.

" />

I lightly deburred all the sharp edges then used my L.E. Wilson chamfer/deburring tool to put a light chamfer on the hole at one end and a heavy one on the other.

" />

The reason for that is to quickly see what end goes on the case and sits on the shoulder. If done right it shouldn’t matter which end you use but I like to keep things consistant, so I only use one end on the case every time.

Its’ use:

Put the end of the tool with the light chamfer over the neck and onto the shoulder of a fired case, put them between the jaws of your calipers and measure the entire length, You may have to wiggle it a little to get them to sit straight. Record that measurement. Lube and size the case, use the tool again to measure the case. Record that measurement. The difference will be the amount you are bumping the shoulder back.

" />

The end result is a simple, very useful, easy to make and use tool that is much needed if you want close, consistant measurements. It took me about an hour to make one and it cost me nothing, these were pieces of scrap from other projects. You can look around the house and probably find something that will work.

" />

The tool itself really doesn’t have any precise tolerances other than keeping the ends square. You can make it 1’’, 1 1/4’’, 2’’ or 4’’ long, 1’’ wide, 2’’ wide, whatever you want, whatever you have on hand to use. The length and width doesn’t matter. Making it as small as possible within reason would be best to minimize any variation during use.

Also, I found out that the one for .308 works for 30-06 and 7.62x54R. It could work on a few other calibers too.

Win a FREE Membership!

Win a FREE Membership!