|

Quoted: Same woman is standing at some of the NTSB media briefings. Why have just one speaker when you have to fill the diversity bingo card. https://www.ar15.com/media/mediaFiles/113152/IMG_4966_png-3095165.JPG View Quote I think those are two different fat brown women. |

|

|

|

|

|

Quoted: I think those are two different fat brown women. View Quote View All Quotes View All Quotes Quoted: Quoted: Same woman is standing at some of the NTSB media briefings. Why have just one speaker when you have to fill the diversity bingo card. https://www.ar15.com/media/mediaFiles/113152/IMG_4966_png-3095165.JPG I think those are two different fat brown women. You may be right. I saw same hair style, same earrings, same face shape, other stuff. |

|

|

|

|

|

|

|

Quoted: @L_JE He is an absolute moron with ZERO credibility. Everything that oozes from his mouth is tripe. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: Dan Gryder - FAA - Asleep at the Wheel. Again. Part II I don't know who this guy is, but I'm having a hard time taking him seriously. He is an absolute moron with ZERO credibility. Everything that oozes from his mouth is tripe. Yep  Dan Gryder Lawsuit Explained! |

|

|

|

Quoted: A subsidiary of the same company that builds the fuselage and installs the plug doors. Blancolirio's video mentions it and shows a jet that's in the process of having the wifi stuff installed and they are accessing the jet through the plug door opening. (Photo needs to be verified) https://www.ar15.com/media/mediaFiles/367483/IMG_7240-3094964.jpg View Quote CRTL + drag image with globe view turned on (hover over "layers" bottom left, click "More" and make sure "Globe view" is selected). https://www.google.com/maps/@35.4016055,-97.6021259,124m/data= |

|

|

|

Quoted: That ladder and shelter is for putting the dome on the top of the aircraft. You can see the 9 windows in the rear, then a gap, then the plugs window. https://www.ar15.com/media/mediaFiles/164047/Screenshot_2024-01-17_181351_jpg-3097992.JPG CRTL + drag image with globe view turned on (hover over "layers" bottom left, click "More" and make sure "Globe view" is selected). https://www.google.com/maps/@35.4016055,-97.6021259,124m/data= View Quote Yeah. In the picture you posted it does look like the plug door is still installed. |

|

|

B-737 900ER DOOR UPDATE! 22 Jan 2024 |

|

|

|

|

|

|

View Quote So now it’s a possible issue with the 737 900er as well? Yikes. |

|

|

|

Alaska Airlines CEO: We found 'many' loose bolts on our Max 9 planes following near-disaster

"I'm angry," Ben Minicucci said. "This happened to Alaska Airlines. It happened to our guests and happened to our people."  The CEO of Alaska Airlines said new, in-house inspections of the carrier's Boeing 737 Max 9 planes in the wake of a near-disaster earlier this month revealed that “many” of the aircraft were found to have loose bolts. In an exclusive interview with NBC News senior correspondent Tom Costello, Alaska Airlines CEO Ben Minicucci discussed the findings of his company's inspections so far since the Jan. 5 incident, in which a panel on one of its Max 9 jets blew out midair on a flight carrying 177 people. “I’m more than frustrated and disappointed,” he said. “I am angry. This happened to Alaska Airlines. It happened to our guests and happened to our people. And — my demand on Boeing is what are they going to do to improve their quality programs in-house.”  There is still no timetable for returning the Boeing-made planes to service because the FAA has not yet issued specific maintenance orders that are required for them to do so. As a result, Alaska Airlines, whose fleet had the highest percentage of Max 9 planes among any major carrier, has spent weeks canceling and rearranging its schedule, leaving thousands of passengers scrambling. Minicucci said the onus is now on Boeing to show how it will improve its quality control and prevent such incidents from unfolding in the future. But out of an abundance of caution, he said, Alaska Airlines is incorporating its own additional oversight on the production line at Boeing.  "We’re sending our audit people to audit their quality control systems and processes to make sure that every aircraft that comes off that production line, that comes to Alaska has the highest levels of excellence and quality," he said. United Airlines CEO Scott Kirby said in a separate interview with CNBC on Wednesday that it is now contemplating a future for its fleet without the Boeing 737 Max 10, a newer version of the popular jet. Link |

|

|

Boeing's Quality Management Failure Explained 737-Max-9 Door 24 Jan 2024 TLDW Saying the Subcontractor that does the fuselage has a team at Boeing because of so many issues with their work. 2 different quality control systems in use with the companies and they don't interface or don't have access to each others. Subcontractor has note in their system about the seal on the plug door in question. Discussion about opening it or removing it. They decide to "open" it to fix the seal. Boeing's quality management system doesn't require an entry for them opening the door, but it does for removing it. Since the door was only "opened" doesn't appear anyone inspected it when the subcontractor was done fixing the seal and closing the door up and the only entry in Boeing's system was the seal being repaired and no quality check by Boeing making sure the 4 door bolts were installed properly or even at all. |

|

|

|

Crazy

|

|

|

|

Inspections in the past 6 months have found loose or missing bolts, improperly drilled holes, non approved fixes to shoddy workmanship, and what else on the 737 MAX? Work performed by Spirit and passed thru Boeing without notice until the end user took notice.

Thursday, December 28, 2023 The FAA is closely monitoring targeted inspections of Boeing 737 MAX airplanes to look for a possible loose bolt in the rudder control system View Quote The company recommended the inspections after "an international operator discovered a bolt with a missing nut while performing routine maintenance on a mechanism in the rudder-control linkage," the Federal Aviation Administration said in a statement Thursday. "The company discovered an additional undelivered aircraft with a nut that was not properly tightened." View Quote August 24, 2023 Boeing has found another significant manufacturing flaw in its 737 MAX aircraft and it's likely to throw a curveball at deliveries of its most popular aircraft. The company says fuselages from its largest contractor, Spirit AeroSystems, have random extra holes drilled in the rear pressurization bulkhead. The Air Current broke the story on Wednesday and said the issue may be widespread. Boeing inspectors reportedly found bulkheads with "hundreds" of misaligned and duplicated holes in the structure, some of which were filled with fasteners. They passed Spirit's quality control inspections. View Quote https://www.avweb.com/aviation-news/extra-holes-drilled-in-max-pressure-bulkheads/ What else is being overlooked? From Spirit Aerosystems and some of their US operations. https://www.spiritaero.com/company/programs/ Boeing 737 In February 2018, Spirit AeroSystems celebrated the delivery of the 10,000th Boeing 737 shipset fuselage, pylon, wing leading edges, thrust reverser and engine nacelle. For more than 50 years, the Boeing 737 has been built in Wichita, Kansas. Today, Spirit makes approximately 70 percent of this narrow-body aircraft for Boeing. Boeing P-8A Poseidon In 2016, Spirit began production of the P-8A, a derivative of the Boeing 737. The program demonstrates Spirit AeroSystems' unique capability to build military-specific aircraft using decades of experience building the 737, making the P-8A more affordable and of the highest quality possible. Boeing 747-8 Spirit builds the forward fuselage section of the famed Boeing 747 wide-body jumbo jet, along with its nacelles, struts and wing leading edge. The aircraft is now purchased and used primarily for cargo freight. Boeing KC-46A Aerial Refueling Tanker Aircraft A military derivative of the Boeing 767, Spirit has manufactured the tanker's forward fuselage (Section 41), strut and nacelle components, and the fixed leading edge since 2013. Spirit assisted in the design of the next-generation tanker, which will replace the aging KC-135 Stratotanker fleet. Boeing 767 Spirit builds the forward fuselage structure and other components for the Boeing 767. While the aircraft is no longer produced for commercial fleets, it's found success by being modified and repurposed as a cargo freighter. The 767-300F is considered a reliable workhorse for premier cargo airlines, including UPS and FedEx. Boeing 777 and 777X In late 2017, Spirit AeroSystems began production on Boeing's next-generation widebody airliner, the 777X, featuring fuel-efficient new engines from GE and a composite folding wing. Spirit provides the forward fuselage, nacelles and struts for both the 777 and 777X. Boeing 787 Spirit AeroSystems delivers a fully integrated fuselage structure for the Boeing 787 Dreamliner. The composite forward fuselage (Section 41) and engine pylons are built in Wichita, Kansas, and the wing fixed leading edge and wing movable leading edge are built in Tulsa, Oklahoma, and Subang, Malaysia. Spirit has been delivering these assemblies and components on the 787 since 2007. In 2016, the 500th unit was delivered to Boeing. View Quote Right now focus is on a improperly installed door that departed in flight. What else is out there to be discovered in a heavy check (6-10 year check) that Spirit passed off ? FAA just said operators need not ground but should inspect the same exact design plug doors on the 737-900ER that was last produced for a decade. Started 2009 and the last one rolled off the line in 2019 No way you could ignore as an end user there is a facility that produces fuselage components as quoted above and not wonder what could be wrong behind the inner panels or outer skin of the aircraft? |

|

|

|

Quoted: Crazy

View Quote Not if you’ve dealt with any of the max issues in the past few years. |

|

|

|

Does Spirit manufacture anything that ends up in a military aircraft?

|

|

|

|

Quoted: Does Spirit manufacture anything that ends up in a military aircraft? View Quote View All Quotes View All Quotes Yes. I read something about them years ago. This is from Wiki but it is accurate: Spirit's principal products are metal and composite structural sub-assemblies ("aerostructures") for Boeing, Airbus, and Bombardier airliners, as well as business aircraft (and their military variants). It also provides various other aerospace products and services. |

|

|

|

Bottom line is that Alaska’s 737 MAX left Boeing without the bolts.

Door doesn’t come off clean if even one bolt is there Door doesn’t come off if all the bolts are loose Bolts being tight have nothing to do with the design But… all these things point to problems at Boeing. Particularly this one…. Where are the bolts? And how can they be somewhere without causing alarm? |

|

|

|

Quoted: Does Spirit manufacture anything that ends up in a military aircraft? View Quote https://en.wikipedia.org/wiki/Boeing_P-8_Poseidon ~170 of them running around. |

|

|

|

|

|

Quoted: Yup, silly me, it was right there, a few posts before mine. View Quote View All Quotes View All Quotes Quoted: Quoted: Does Spirit manufacture anything that ends up in a military aircraft? Yup, silly me, it was right there, a few posts before mine. I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). |

|

|

|

Boeing 737 Max-9 cleared for takeoff

Cleared For Takeoff! Boeing 737 Max-9 UPDATE 26 Jan 2024 |

|

|

|

Quoted: Bottom line is that Alaska's 737 MAX left Boeing without the bolts. Door doesn't come off clean if even one bolt is there Door doesn't come off if all the bolts are loose Bolts being tight have nothing to do with the design But all these things point to problems at Boeing. Particularly this one . Where are the bolts? And how can they be somewhere without causing alarm? View Quote There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. |

|

|

|

Quoted: There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. View Quote View All Quotes View All Quotes Quoted: There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. The Alaska Airlines jet that lost a door mid-flight forcing an emergency landing had been banned from long-distance flights over water after a cabin pressure warning light illuminated on three prior flights. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  |

|

|

|

Quoted: I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). View Quote Fucking MD executive business model and Jim McNerney. The gifts that keep giving. |

|

|

|

Quoted: Fucking MD executive business model and Jim McNerney. The gifts that keep giving. View Quote View All Quotes View All Quotes Quoted: Quoted: I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). Fucking MD executive business model and Jim McNerney. The gifts that keep giving. At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes in house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture. |

|

|

|

Quoted: Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  View Quote View All Quotes View All Quotes Quoted: Quoted: There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. The Alaska Airlines jet that lost a door mid-flight forcing an emergency landing had been banned from long-distance flights over water after a cabin pressure warning light illuminated on three prior flights. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  A lot of that is similar to what I wrote in the other thread. See the last page. https://www.ar15.com/forums/general/Alaska-Airlines-737-loses-a-door-in-flight-/5-2697871/&page=8&anc=107642154#i107642154 |

|

|

|

Quoted: A lot of that is similar to what I wrote in the other thread. See the last page. https://www.ar15.com/forums/general/Alaska-Airlines-737-loses-a-door-in-flight-/5-2697871/&page=8&anc=107642154#i107642154 View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. The Alaska Airlines jet that lost a door mid-flight forcing an emergency landing had been banned from long-distance flights over water after a cabin pressure warning light illuminated on three prior flights. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  A lot of that is similar to what I wrote in the other thread. See the last page. https://www.ar15.com/forums/general/Alaska-Airlines-737-loses-a-door-in-flight-/5-2697871/&page=8&anc=107642154#i107642154 When the plane pressurizes would that take tension off the spring and allow for more slop so to speak so the bolts could vibrate loose? Another theory I heard from a friend that is a mechanic is the bolts are a PITA to get to so they may have just left them off which would explain multiple planes having issues. |

|

|

|

Quoted: At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). Fucking MD executive business model and Jim McNerney. The gifts that keep giving. At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture. I still have a hard time letting it go too. PNW was ate up with that mentality long before the merger. The old heritage MD programs remained better places for an engineer many years after the merger/buyout. All I can figure is that explanation (that MD wrecked everything and Boeing was doing great per merger) is so much simpler than the truth, and more palatable to more people. I really didn't have a reason to be biased one way or another but it was immediately apparent to me as a young engineer that the grass was greener out east. For an engineer anyway. It remained that way for quite a while. I think that last BDS CEO (heritage BA manager ironically) was really the end for BDS. I guess the things that drove me away weren't specific E-lvl driven policies (like outsourcing everything), as much as just general complacency and laziness. Both kind of go hand in hand I suppose. Inevitable end is a buildings full of low level managers selling dumb ideas to dumb customers. |

|

|

|

Quoted: At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). Fucking MD executive business model and Jim McNerney. The gifts that keep giving. At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture.    Does the Boeing Space Center at Kent WA even exist anymore? There were National Asset type labs there as well. |

|

|

|

Quoted: They did the same thing at Boeing Huntsville: Lost most if not all the labs, the Boeing Library, even Security went to contractors instead of employees.    Does the Boeing Space Center at Kent WA even exist anymore? There were National Asset type labs there as well. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: Quoted: I think most of what comprises Spirit Aerostructures now was formerly Boeing Commercial Aircraft facilities. Seems like about 20yrs ago Boeing had a big push to externalize all the manufacturing, sold off a few of the plants. I remember them telling us the vision was to become "high level integrator". Product lines have probably expanded a bit but they are still primarily commercial parts (and commercial derivatives as noted above). Fucking MD executive business model and Jim McNerney. The gifts that keep giving. At the buyout by Boeing, St. Louis was still operating every technology and shop to build airplanes house. Including a million square foot machine shop, chem mill and anodize shops, two composite fab shops, two welding shops, a sheet metal shop of about a million square feet that included NC routing, hydroforming, heat treat, and at least four machine shops that supported testing. Several materials labs. And more. Boeing was losing money on every airplane built in Seattle because they had piss poor cost tracking and didn't know what each airframe cost, plus hundreds of buildings and thousands of acres scattered all over the Seattle region that were costs. Boeing stripped St. Louis facilities, then instituted the manager-worker management model, bypassing the best leaders in engineering (the business school "any manager can manage any group" tripe). We damn near lost the Polysonic Wind Tunnel, which should be treated as a national asset. The high speed machining facility built on to the old machine shop was filled with new tools that were still wrapped when that plus the sheet metal and composites shop were sold to GZN. We didn't have even a small autoclave to support research afterwards. MDC wasn't perfect, just a light year better place to work than that mess in Seattle. Hell, Boeing sucked so much that Bill Boeing got out in the thirties and returned to building furniture.    Does the Boeing Space Center at Kent WA even exist anymore? There were National Asset type labs there as well. I worked a Super Guppy payload job down there in the shipping department. Shipping wanted to put 4000 pounds of ballast in the airplane to haul our pole model. That meant the ceiling was so limited the airplane couldn't fly direct to Holloman over mountains and didn't have enough range to make the trip around nonstop. A Seattle designer I had worked with on JSF and I had a payload designed by noon that needed no ballast, and most of the fixturing parts were welded by noon the next day. We bought some bits and pieces from the Eagle hardware store in Tukwila. (We used floor jacks to support the extremities of the model.) The CG problem was fixed by pointing the nose of the fixture aft in the bay. I thought that was fairly well obvious. The hardest part of that job was designing a stand that spread the loads on the fragile Guppy floor to its edges. Plus I didn't have a couple of references that would have sped up my work, and no computer. The Kent site reminded me of a college campus. There were still two or three big satellite antennas in the field on the east side of the site, too. |

|

|

|

Quoted: When the plane pressurizes would that take tension off the spring and allow for more slop so to speak so the bolts could vibrate loose? Another theory I heard from a friend that is a mechanic is the bolts are a PITA to get to so they may have just left them off which would explain multiple planes having issues. View Quote View All Quotes View All Quotes Quoted: Quoted: Quoted: Quoted: There has to have been something in at least one of the locking holes or the door lifts up and sits ajar due to the lift assist springs. Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. The Alaska Airlines jet that lost a door mid-flight forcing an emergency landing had been banned from long-distance flights over water after a cabin pressure warning light illuminated on three prior flights. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  A lot of that is similar to what I wrote in the other thread. See the last page. https://www.ar15.com/forums/general/Alaska-Airlines-737-loses-a-door-in-flight-/5-2697871/&page=8&anc=107642154#i107642154 When the plane pressurizes would that take tension off the spring and allow for more slop so to speak so the bolts could vibrate loose? Another theory I heard from a friend that is a mechanic is the bolts are a PITA to get to so they may have just left them off which would explain multiple planes having issues. The door bears up against the tabs, upper hooks, and lower hinges when the airplane is pressurized. The bolts could be loose, they're certainly in clearance fit holes. I'll bet the bottom bolts are a pain to install, especially if a longer grip length has been substituted. |

|

|

|

Quoted: Ok, didn't know the springs are that strong. (are we sure?) So help me think this through. If you're installing the door. You're saying it won't stay in place without a pin. But that could be anything while I'm getting the bolts... a screw driver, a pencil even. Then I don't get the bolts and we fly off.... Or I could put a bolt in there without a nut and we fly off. If the assist springs are that strong they are applying some pressure to that lone bolt. It stays for a few months slowly working free... Or maybe I put all four bolts in and no nuts, and over the two months they rattle out against the assist spring pressure. What I'm having trouble buying is that four bolt are in with nuts. Even not properly drilled and pinned I don't see them all coming out so quickly. However, I can see this as likely from a mistake point of view. I'm installing them, spin the nuts on by hand, darn, my Pittsburg ratchet is missing from my shift working on a 767 tanker,... off I go to look for it, shift over... I go home, bolts are only hand tight and the pins never installed... some point in this I or somebody closes out the paperwork. Another clue is the cabin pressure warnings that plane was getting over time. Assuming the door was leaking, can that happen with even a single bolt in place? I don't think so. I think there would need to be no bolts for the door to start moving enough to create a leak.  View Quote Quoted: A lot of that is similar to what I wrote in the other thread. See the last page. https://www.ar15.com/forums/general/Alaska-Airlines-737-loses-a-door-in-flight-/5-2697871/&page=8&anc=107642154#i107642154 View Quote Agreed, but there was an additional failure point. The bolts have backed out of the aft lower sliding hinge assembly. It was left attached to the aircraft as seen behind the plastic sheet. The door as found is not bent or distorted at this location. I am going with all 4 of those smaller bolts that were shown backing out in one of the inspection photos from another aircraft was the case for this aircraft as well. You can see the bolts installed peeking through in the background behind her wrist on the other sliding hinge assembly. Also note the damaged upper guide track torn away where the locking bolt passes through. Door... damaged with one damaged guide track visible (NTSB structures engineer said both top guide tracks were fractured), and missing lower sliding hinge assembly.  Additional bolts, different than the locking bolts, found during inspection of another aircraft. (Right lower and upper background) Sliding hinge assembly from door left behind...... |

|

|

|

You can't determine what is hanging behind the plastic. The part showing has two holes.

|

|

|

|

https://www.wsj.com/business/airlines/boeing-finds-new-problem-with-737-max-fuselages-8ee225b9?st=08kc9fixtg8d1p6&reflink=desktopwebshare_permalink

The hits keep coming. Boeing is reworking 50 undelivered 737 MAX jets after a supplier’s employee recently found misdrilled holes on some fuselages, a new production snafu for the aircraft manufacturer. Spirit AeroSystems, which has been at the center of quality issues affecting 737s, supplied the fuselages. Boeing said that the issue could delay some deliveries in the near term and that existing 737s can keep flying. “This is the only course of action given our commitment to deliver perfect airplanes every time,” Boeing’s commercial chief Stan Deal said in a memo to staff on Sunday. Boeing said it is finalizing instructions for the rework and expects to know how long it will take in coming days. Deal said the employee flagged to his manager two holes that may not have been drilled exactly to the jet maker’s requirements. Delays will allow the company to inspect and, if necessary, fix any problems, he said. A Spirit spokesman said the company is aware of the issue and is in close communication with Boeing. Last year, misdrilled holes by Spirit on the aft bulkhead of some MAX jets led to production delays. View Quote |

|

|

|

Quoted: https://www.wsj.com/business/airlines/boeing-finds-new-problem-with-737-max-fuselages-8ee225b9?st=08kc9fixtg8d1p6&reflink=desktopwebshare_permalink The hits keep coming. View Quote View All Quotes View All Quotes Quoted: https://www.wsj.com/business/airlines/boeing-finds-new-problem-with-737-max-fuselages-8ee225b9?st=08kc9fixtg8d1p6&reflink=desktopwebshare_permalink The hits keep coming. Boeing is reworking 50 undelivered 737 MAX jets after a supplier's employee recently found misdrilled holes on some fuselages, a new production snafu for the aircraft manufacturer. Spirit AeroSystems, which has been at the center of quality issues affecting 737s, supplied the fuselages. Boeing said that the issue could delay some deliveries in the near term and that existing 737s can keep flying. "This is the only course of action given our commitment to deliver perfect airplanes every time," Boeing's commercial chief Stan Deal said in a memo to staff on Sunday. Boeing said it is finalizing instructions for the rework and expects to know how long it will take in coming days. Deal said the employee flagged to his manager two holes that may not have been drilled exactly to the jet maker's requirements. Delays will allow the company to inspect and, if necessary, fix any problems, he said. A Spirit spokesman said the company is aware of the issue and is in close communication with Boeing. Last year, misdrilled holes by Spirit on the aft bulkhead of some MAX jets led to production delays. That's an old problem. It won't get fixed without fixing the employees, starting with the manager/schedule pushers. |

|

|

|

https://www.msn.com/en-us/travel/news/boeing-737-max-missing-critical-bolts-in-alaska-airlines-blowout-ntsb-says/ar-BB1hSJ26

Just as we suspected. The plane left Boeing without the bolts installed. |

|

|

|

Quoted: https://www.msn.com/en-us/travel/news/boeing-737-max-missing-critical-bolts-in-alaska-airlines-blowout-ntsb-says/ar-BB1hSJ26 Just as we suspected. The plane left Boeing without the bolts installed. View Quote View All Quotes View All Quotes Quoted: https://www.msn.com/en-us/travel/news/boeing-737-max-missing-critical-bolts-in-alaska-airlines-blowout-ntsb-says/ar-BB1hSJ26 Just as we suspected. The plane left Boeing without the bolts installed. Wow. The report had a lot more info that I expected. The NTSB's site is ridiculously slow right now, so I'll include the relevant (damning) portion of the report: The Manufacturing Records Group traveled to Boeing’s Renton, Washington, facility to review manufacturing records for the accident airplane specific to the left MED plug area. According to records, the accident fuselage arrived at Boeing’s Renton facility by rail on August 31, 2023. During the manufacturing process, if any defects or discrepancies were found, a Non- Conformance Record (NCR) or a disposition required NCR were generated. On September 1, 2023, records show that NCR 1450292531 was created noting five damaged rivets on the edge frame forward of the left MED plug. See figure 14 for rivet locations.  Figure 14. Photo on the left shows the five locations of the damaged rivets. Photo on the right is a close-up of a damaged rivet. (Source: Boeing. Image Copyright © Boeing. Reproduced with permission.) Documents and photos show that to perform the replacement of the damaged rivets, access to the rivets required opening the left MED plug (see figure 15). To open the MED plug, the two vertical movement arrestor bolts and two upper guide track bolts had to be removed.  Figure 15. Photo showing the MED plug opened to work on damaged rivets. (Source: Spirit AeroSystems.) Records show the rivets were replaced per engineering requirements on Non-Conformance (NC) Order 145-8987-RSHK-1296-002NC completed on September 19, 2023, by Spirit AeroSystems personnel. Photo documentation obtained from Boeing shows evidence of the left-hand MED plug closed with no retention hardware (bolts) in the three visible locations (the aft upper guide track is covered with insulation and cannot be seen in the photo). See figure 16. This image was attached to a text message between Boeing team members on September 19, 2023, around 1839 local. These Boeing personnel were discussing interior restoration after the rivet rework was completed during second shift operations that day.  Figure 16. Photo showing the left MED plug immediately before interior restoration and the circles show the three locations without the retaining bolts, two vertical movement arrestor bolts and the forward upper guide track bolt. The aft upper guide track is covered with insulation and cannot be seen in the photo. (Source: Boeing. Image Copyright © Boeing. Reproduced with permission.) |

|

|

|

|

|

|

|

Quoted: Bottom line is that Alaska’s 737 MAX left Boeing without the bolts… Particularly this one…. Where are the bolts? And how can they be somewhere without causing alarm? View Quote I have a dedicated jar for left over bolts and stuff when working on cars and tractors. I can’t believe I’m more professional than Boeing! |

|

|

https://www.boeing.com/737-9-updates#updates

|

|

|

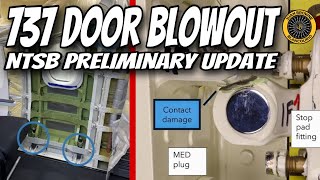

NTSB Preliminary Report Alaska #1282 Door Plug Blowout |

|

|

|

Boeing has fired the head of their 737 MAX program

Boeing announced Wednesday that the head of the company's 737 Max program is leaving the company in a management shake-up in the wake of a January mishap that has damaged the aircraft manufacturer's reputation and cost it billions of dollars in value. Boeing Executive Vice President and CEO of Boeing Commercial Airplanes Stanley A. Deal announced several leadership changes in an email to employees Wednesday, including that Ed Clark, the head of the company's Boeing’s 737 Max program, has been replaced. “Ed departs with my, and our, deepest gratitude for his many significant contributions over nearly 18 years of dedicated service to Boeing,” Deal said. View Quote |

|

|

|

Quoted: Having that top aft guide track fitting not in the photo was bugging me since something has to hold the door down about 2 inches against the springs. Heck, someone could have just shoved their ball point pen through that hole and it held up for 450 hours. Then I seen the second from the bottom right stop fitting. Damn zip tie..... (pg. 17 of report blue circles not mine) https://i.imgur.com/MOfOo34.jpg From my understanding Spirit also had to repair the door seal. The photo in the report page 16 lists the source of photo as Spirit and has an employee holding the dislodged seal. Possible scenario. Boeing employee opens door and takes bolts with them so they are not lost. Spirit does the rework and possibly closes the door and rigs door closed with a zip tie and whatever could be hiding behind that insulation on top left. Check seal from outside or whatever procedure is, sign off on the work call it a day. Appears no documented sign-off for opening and closing the door have been found. Next thing you know the next crew gets orders to install the insulation and panels. View Quote View All Quotes View All Quotes Quoted: Having that top aft guide track fitting not in the photo was bugging me since something has to hold the door down about 2 inches against the springs. Heck, someone could have just shoved their ball point pen through that hole and it held up for 450 hours. Then I seen the second from the bottom right stop fitting. Damn zip tie..... (pg. 17 of report blue circles not mine) https://i.imgur.com/MOfOo34.jpg From my understanding Spirit also had to repair the door seal. The photo in the report page 16 lists the source of photo as Spirit and has an employee holding the dislodged seal. Possible scenario. Boeing employee opens door and takes bolts with them so they are not lost. Spirit does the rework and possibly closes the door and rigs door closed with a zip tie and whatever could be hiding behind that insulation on top left. Check seal from outside or whatever procedure is, sign off on the work call it a day. Records show the rivets were replaced per engineering requirements on Non-Conformance (NC) Order 145-8987-RSHK-1296-002NC completed on September 19, 2023, by Spirit AeroSystems personnel. Photo documentation obtained from Boeing shows evidence of the left-hand MED plug closed with no retention hardware (bolts) in the three visible locations (the aft upper guide track is covered with insulation and cannot be seen in the photo). See figure 16. This image was attached to a text message between Boeing team members on September 19, 2023, around 1839 local. These Boeing personnel were discussing interior restoration after the rivet rework was completed during second shift operations that day. The investigation continues to determine what manufacturing documents were used to authorize the opening and closing of the left MED plug during the rivet rework. Appears no documented sign-off for opening and closing the door have been found. Next thing you know the next crew gets orders to install the insulation and panels. The hardware should have been bagged. In the old days it would have been hung on the door. Nowadays it's probably considered a foreign object, and it doesn't meet lean requirements where there are no uninstalled parts present. Also, Boeing produced junk well before it bought MDC. The myth about engineering prowess is bullshit and should go away. There were features in 747-8 with questionable details that had not been tested since the B-52 program and they are sufficiently different to warrant a new look. An unethical , immoral international company to its core. Don't make the mistake believing it's a US company. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.