|

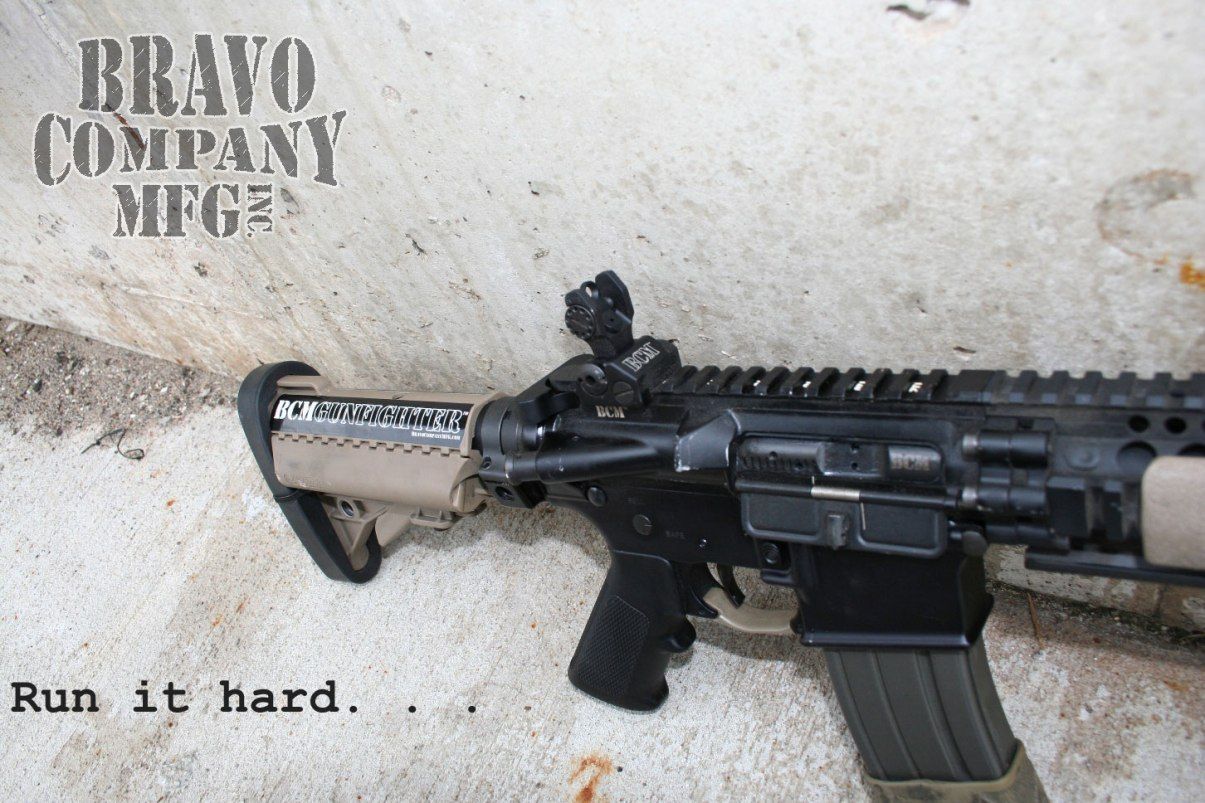

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started.

In an effort to put as much info in one place as possible and have a centralized area for reference, I have put together this post in hopes it generates more light than heat. Please forgive my grammar, spelling and syntax, they are not my strong points, and much of the following information has been cut and pasted from various emails we have answered in the past years. So if you see a paragraph here that answered a question you had last fall, last summer, last year, you are correct – I just cut, pasted and reposted it here ?.

Much of these specs have been posted on our website in one form or another for years, but there are more details behind these features. •M4 Feed Ramp Barrel Extension •M4 Feed Ramp Flat Top Receiver •T-Marked Upper Receivers •USGI 5.56mm NATO Chambers •Independently Certified Mil-Spec 11595E Barrel Steel •Chrome Lined Bore and Chamber •Manganese Phosphate Barrel Finish on entire barrel •Mil-Spec F-Marked Forged Front Sights •Taper Pinned Front Sight Base •USGI Government Profile Barrels •HPT (High Pressure Test, per Milspec) Barrels •MPI (Magnetic Particle Inspected, per Milspec) Barrels •Bolt machined from Mil-Spec Carpenter No. 158® steel •HPT Bolt (High Pressure Tested/ Proof) •MPI Bolt (Magnetic Particle Inspected) •Shot Peened Bolt •Chrome Lined Carrier (AUTO) •Chrome Lined Gas Key •Gas Key Hardened to USGI Specifications •Grade 8 Hardened Fasteners Key •Staked Per Mil-Spec •Tool Steel Extractor •BCM® Extractor Spring •Black Extractor Insert •Receivers Machined from Aluminum Forgings 7075-T6 •Receivers Hardcoat Anodize per MIL-A-8625F, Type III, Class 2 •BCM® Milspec 7075-T6 Receiver Extension •USGI Mold M4 Stock Staked M4 Lock Nut •USGI H Buffer (1 USGI Tungsten, 2 Steel) •Magpul MOE Enhanced Trigger Guard •Low Shelf for RDIAS installation •Low Shelf for Accuwedge use •Un-notched Hammer compatible with 9mm use •Fire Controls marked SAFE and SEMI And this narrative has also been posted on our webpages since 2005; M4 Feed Ramp Barrel Extension M4 Feed Ramp Flat Top Receiver In developing the USGI M4 carbine as one of the primary weapons for today’s infantry, some modifications were performed to the original M16 platform to enhance the reliability of the shorter barreled carbines. With the shorter carbine gas system and the increased gas port pressure, the carbine cycled faster, and at times the cycle rate could be faster than the magazine would feed ammunition. One of the modifications done to increase reliable feeding included enhancing the angle and the length of the feed ramps. This USGI modification was done to both the barrel extension and the upper receiver, creating a longer and steeper feed ramp. These Mil-Spec M4 feed ramps are part of the original CNC manufacturing process. As a result, the factory machined M4 feed ramps on the receiver are hard coat anodized which adds significant strength to the aluminum. This feature is offered on all BCM uppers and all BCM barrels. T-Marked Upper Receiver The contemporary M16/M4 rifle is built around the concept of modularity. All of the BCM flat top uppers feature a USGI type laser etched T-marks to provide addressing for the remounting of tactical accessories such as optics, laser sights, etc. This enables the weapon platform to be easily configured and then accurately reconfigured for each specific mission. USGI 1/7 Twist Rate The USGI 1/7 twist rate of all of the BCM barrels is the preferred twist rate by most professional infantryman. This twist rate has proven very versatile and can effectively run the new heavier 5.56 ammo that is hugely popular with military and private security personal for its’ superior ballistics. Mil-Spec 11595E - Barrel Steel BCM barrel steel is Mil-Spec per MIL-B-11595E. This grade (CMV) of steel is a Mil-Spec steel used in the USGI M16 family of rifles; it is stronger and will last longer than the typical barrels offered in the commercial market. The Mil-Spec grade steel gets its’ additional strength and rigidity from an increase in carbon and/or vanadium in the alloy. This will offer increased barrel life and performance through use in all types of extreme environments and temperatures. Chrome Bore and Chamber One of the first modifications that were made to the original M16 in the mid 1960’s was the addition of the chrome lined bore and chamber. It is now a world wide standard in the industry for a battle rifle. The chrome bore and chamber is harder than the barrel steel and on the USGI M16/M4 rifles will aid in chambering, extraction, and reliability. It increases velocity, and also resist against fouling and corrosion from extended use in the field. This gives the end user a longer barrel life with less required time in maintenance and cleaning. Manganese Phosphate Barrel Finish Barrels are parkerized with the manganese phosphate finish (Mil-Spec A-A-59267). Military specifications also state that the entire barrel surface is phosphate finished to create a porous surface to absorb oil as to resist against corrosion from the elements. BCM barrels are phosphated before installation of front sights. This is a much more extensive assembly operation, but insures that the entire barrel is finished and protected . . .even under the front sight base. 5.56 NATO Chambers The USGI 5.56 NATO chamber is the best choice for effective deployment, reliability, and compatibility, of higher chamber pressures of military ammo. Mil-Spec F-Marked Forged Front Sight Bases Mil-Spec for rifles issued to the troops require taller front sight bases on all flat top AR rifles. Many commercial offerings use M16A2 height front sight bases on all of their barrels regardless of what type of upper it is installed on. As a result, owners of rifles and carbines with the flat top receiver configuration can have problems getting a proper 'zero' for elevation with Mil-Spec back up iron sights. As all of the BCM uppers are built for flat top uppers, all have the proper Mil-Spec F marked front sight base to insure the correct height for iron sight zeroing when using military iron sights. Mil-Spec taper pins secure the forged front sight base with the sling swivel secured by tubular rivets. Government Barrel Profiles Duty rifles are built to be carried - day in and day out. The USGI barrel profiles (often referred to as the Government Profile) enable the operator to carry their weapon for longer periods of time and deploy them faster than the heavier commercial H-Barrel counterparts. The government profile barrel is also compatible with the current M203 mounting systems. HPT / MP Inspected Barrels Military specifications require that barrels undergo a HPT (High-Pressure Test) load as a part of quality assurance procedures. Commonly referred to as a proof load, the M197 HPT is rated for 70,000 psi. BCM barrels are proof loaded and then MPI (Magnetic Particle Inspected) to detect any possible flaws in the barrels surface. The barrels are MP inspected with both circular and longitudinal magnetic fields per ASTME1444-01 (current Mil-Spec) to assure a high quality finished product. All BCM barrels are marked HP MP as our proof load marking. Since the BCM program was first introduced in 2005 we have always received lots of questions as to the what/ why/ and how the program was put together. As years went on the consumer became more educated and the questions more sophisticated, which is a good thing for a company like ours.

The BCM program was basically designed with the philosophy of “no shortcuts”. Whether the consumer will notice the short cut or not, does not matter; “no shortcuts”. The specs and standards are set up so that if I or anyone was in the fight of their life, would I be 100% confident I could grab any BCM gun off the rack it would be good enough to take to a gunfight. That is why we use our tag line: “Professional Grade Weaponry™”. For years the commercial market has built versions of the AR15 with the freedom to implement a variety of cost savings measures in an effort to more effectively compete in the market place. To 95% of shooters these cost saving measures would never affect the performance of their rifle with the type of use it would see in its life span. But to the very small percentage of commercial customers who either required or desired their carbine to be built to a certain standard, we were proud and hopeful to offer BCM as possible option that could fit their needs. But what are they differences? Quite frankly there are so many, it can be exhaustive to list them all. Every time I think I have a complete list, I am reminded of another. But let’s put some of them out there, many of which are rarely mentioned. Please note that many specifics and technical details of the differences are considered intellectual property and won’t be disclosed. Also we would not share supply or sourcing information, or photos of gauging, fixturing, or set ups. Those can be expensive to develop and perfect. We are going to be careful not to disclose more of a road map for the competition to follow.

Butt stock Starting at the rear of the carbine, the BCM M4 stock is based on the USGI mold. It is built to milspec dimensions in every respect, including the composition of the polymer. Even the latch hardware receives the correct heat treat, and secured with lock nut and roll pin. (Our A2 stock includes metal butt plates, per spec)

USGI M4 Stock on left/ Commericial M4 stock on right

7075-T6 Receiver Extension The BCM receiver extension is machined from 7075-T6 aluminum. It is machined to the government print; respective to material, manufacturing process, dimensions, hard coat anodizing, and it even has the dry film lube on the interior ID. The only non Milspec modification is that ours are drilled for 6 positions, as we felt it would be more marketable, but not really sure it makes a big difference. This part ends up costing us about double that of 6061 tubes that are machined to a milspec OD or a commercial OD. Most of the milspec dimension tubes on the market are 6061. We run our own product with 7075-T6 (OEM inquiries are welcome).

Staking the lock nut The receiver extension is installed in the BCM lower receiver and held in place with a M4 lock nut, and then the end plate is staked to hold the nut in place. Milspecs do not allow for a thread locking compound and we do not advocate using one. It makes stock removal a big mess, and it’s not needed if the stock in installed properly. We built a special staking tool, to fit perfectly on M4 lock nuts and all end plates are staked to insure they stay secure. (Sorry, we don’t offer them for sale) If you run your carbine hard and your lock nut is not staked in place you will end up with problems of the nut coming loose, end plate coming loose, receiver extension rotating, rear take down detent spring getting lost out of the back of the receiver, maybe losing your buffer detent inside your receiver, maybe locking up your carrier, etc.

Milspec H Buffers BCM carbines come standard with H buffers. There are both “commercial” Hbuffers and Milspec ones. The commercial ones are almost as heavy. They use a much less expensive carbide/tungsten of buffer weight. The weight is about 10% lighter, but costs about half as much. I believe that spec is the milspec for the Canadian military. However Uncle Sam only calls out for the full tungsten weights in the H series of buffers. So that is what comes in all BCM guns.

Lower Receivers BCM lower receivers are machined with a lower rear shelf. This is an added feature for customer interested in owning a RDIAS, as they will only fit in low shelf receivers. Also, if a customer wants to add an Accuwedge, you will need a low shelf as well for it to properly fit without trimming 50% of it away.

Semi auto hammer The hammer is the non-notched version of a semi auto hammer. Not having the notching offers an increased reliability when using a SP1 type of carrier (with an un-shrouded firing pin). The notched hammers can bind up on the un-shrouded carriers if the disco lets loose. If your carbine is a range toy, its ok for the hammer to lock up when your disco malfunctions, but if you carry your carbine in the line of duty that is a liability I would not be interest in having. Another small benefit to the non-notched semi auto hammer is it will function with a 9mm conversion if you every choice to set up your lower in that configuration.

Dry Film Lube One of the most common questions/concerns/complaints we get on the BCM upper receiver is the interior finish. Some folks think its unfinished anodizing, or worn finish, or some type of problem. What you are seeing is a dry film lube and it’s a good thing. Many commercial upper receivers may skip that step as it is a cost savings, and most folks would not notice the difference. But Uncle Sam wants it on there, and so does BCM. The dry film lube is a grayish milky type finish. It is sprayed on the interior after the hard coat anodizing is applied. It is then baked into the receiver for about 45 minutes at 250 degrees. The dry film lube is just what it sounds like. It adds lubricity to the interior of the receiver where the bolt group and charging handle travel. It’s a good thing.

Milspec Forward Assist Something most folks will never notice is the BCM forward assist. Commercial forward assists have pawls that are machined from castings, and the caps are simply press fit on. The milspec/BCM forward assists have pawls machined from tool steel, heat treated assemblies, with caps press fit, drilled and roll pinned. The Milspec unit is a much stronger assembly. I have seen commercial ones break, I have yet to see a Milspec one break. A broken pawl lodged in your upper group is a bad day. Yes, I know most folks don’t do S-P-O-R-T-S anymore, and we do a version of tap-rack-roll-bang, so maybe it doesn’t matter what quality of forward assist is in your carbine. But one is the correct milspec and one is not. The Milspec costs double, and it’s in your BCM carbine.

F-Front Sight Base The F-front sight base is secured with taper pins instead of straight dowel pins. This process takes approximately twice as long (therefore costs about twice as much), but offers a stronger assembled unit. The holes have to be first drilled then reamed (2/0) to a specific depth. This assembly is stronger because with a tapered pin and tapered bore, more force driving the pin provides for more positive contact with the barrel and FSB. With straight dowel pins, more force on the pin just changes the position of the pin. This final machining and assembly is done to parts that have already been phosphate (as required by the Milspec), so there may be handling and assembly marks. BCM receivers have machined T-markings filled with paint. Most other receivers have laser t-markings. Current prints call for machined t-markings, so that is what is featured on a BCM. That type of set up does cost a bit more. Not really sure it makes much difference though. But it’s on the print, so it’s on the carbine.

BCM Carriers The carrier is chrome lined (where the bolt travels). We have built gauging at our shop (min and max, based on the call outs) to insure parts are in spec before they are in service. We check the ID at both sides of the carrier, and we check the OD. Min and max on the ID is critical as this is where the bolt/bolt rings ride to keep the gas system pressurized, (like piston rings in a combustion motor). The OD of the carrier is also important as it will determine how it moves or is restricted when running inside the upper. We also use our custom built gauging to check min/max on carrier length, and position of the cam track. Gas Key We have developed a similar set of min/max gauges to check the ID and depth of the carrier key for gas tube insertion; another important component in keeping the semi auto gun running. BCM gas key are also chrome lined and heat treated per gov specs, and secured with grade 8 US made fasteners. Many commercial carbines use the less expensive keys and chicom fasteners, and that means softer. The BCM gas key is staked with the hardened fasteners with our staking fixture. You will probably never notice it as a casual shooter, but once the carbine is run hard and put through its paces a softer commercial gas key and softer chicom fastener will yield a softer staking, and is the most common failure point as the carbine begins short stroking because the gas system has lost pressure.

BCM Bolts BCM bolts are machined from Carpenter 158® steel. Many commercial bolts are machined from 8620, 4140, 9310, etc. All of which cost a fraction of cost of the real milspec material. The material costs quite a bit less and have carrying costs that are significantly less due the easy accessibility of those types of steels. Bolt heat treating is one of the most critical processes in producing a quality product. The bolt sees a tremendous amount of stress inside the weapon system. The bolt needs to be hardened properly to last, but cannot be too brittle for it would be prone to cracking. While the surface needs to be hard, the center of the bolt needs to be softer in order for the bolt to serve its life span. This is another area where it’s easy to short cut, or complicated to complete properly – depending on your point of view. Milspecs have a recommended heat treat procedure to include, stress relieving, carburizing, quench, tempering, etc, but a very specific call out for resulting effective case depth hardness. The BCM bolts meet the standard. Shot peening. Basically its media blasted against a surface. It is done after the heat treating and grinding. Most commercially available bolts do not include this step, but the Milspec requires it. More general info can be found here; http://en.wikipedia.org/wiki/Shot_peening So if we blast media against the surface of a bolt, does that mean its “Milspec”? No. I suppose you could place the items in a spinning drum while media blasts the parts. The parts spin around for a predetermined amount of time and then they are removed. Parts are now shot peened? Ok. Parts are now Milspec? Hardly. Who knows which parts got exposed to the shot, who knows for how long they were exposed, who knows that any standard was really met? Who knows if the goals were accomplished? Milspec bolts are shot peened per Mil-S-13165, and the call outs are very specific, as the type of media, the intensity of the media, and the areas to be covered on the part. The specifics of which will not be disclosed in an open forum, but the BCM bolt meets the standard. Regarding the cam pin, firing pin, firing pin retaining pin, gas key, fasteners, etc… all parts are sourced separately for our products. A final inspection, assembly, and test firing of BCGs are done here. (same with all small parts on the carbine) Chrome lined barrels can be almost anything in the commercial market. There are a variety of ways to chrome a bore, most of which cost less than the milspec method. The call outs for hard chrome on Milspec barrels are different in the chamber than the bore and very specific to min thickness, with the bore having a higher min film thickness. It is this same call out that requires; all non chrome plated surfaces to have phosphate coating (Mil-Std-171). BCM barrels are chromed per print requirements.

(just as a note, HPT is not done on a completed rifle. ) Regarding a HPT/MPI process on bolts and barrels. The biggest differences will be the following details in the Milspec Requirements: 1) Independently certified 11595E Barrel Steel vs. a 4150, 4150 Mod, or CMV variant 2) HPT on barrels 3) HPT on bolts 4) An MPI process that is specific to the procedure, acceptance criteria and exclusion criteria as written into the Mil STD. Those 4 things have a sum greater than it parts and must ALL be done in order to meet the standard. Number 1 is critical because if you do not start with 11595E independently certified steel you will NOT be able to use the MILSPEC standards for MPI acceptance (#4).

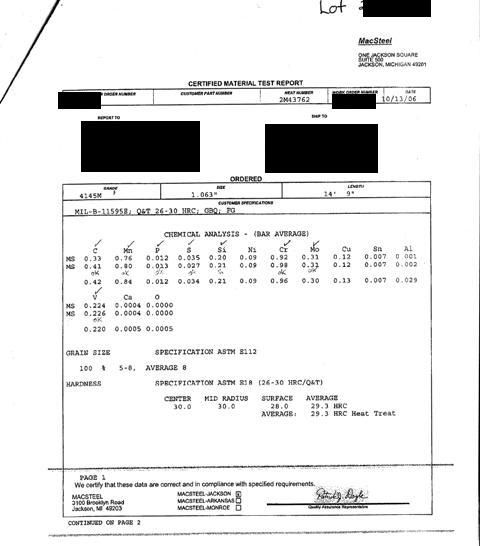

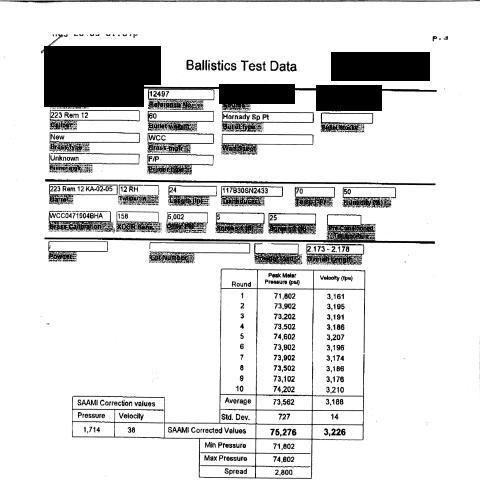

This is an example of one of our 11595 steel certs. (page 1 of a 5 or 6 page document) (our IP/Corp info redacted) A proof load is a round that is manufactured to a larger PSI that would be normally fired in the respective chamber. NATO proofs are usually about 30% beyond the standard Milspec PSIs. For a 5.56 NATO Chamber that would put a HPT over 70 PSI. Below is the data sheet for one the batches of proof loads. (our IP/Corp info redacted)

Number 2 & 3 are important in that they stress the barrel blank and the bolt. (They are NOT done at final assembly) This stress is designed to push a product across failures doorstep so that during MP inspection the flaws are revealed before the weapon system reveals the flaws early in the field.

Number 4 seems to always be overlooked in casual discussions. The MPI is a test. A test is only as good or effective as the parameters set up, and the test can be set up any way you want. As stated in our published ad copy, we set ours up directly as the Milspec and ASTME requires. Which means it is set up to only “pass” a flawless piece of steel. Free from inclusions, stringers and of course cracks. I would assume any manufacture would write a PO to exclude any cracks; size, shape, depth, or length. But it would be impossible to exclude/“fail” inclusions, stringers & cracks on barrel that were not machined from 11595E steel. The failure rate on non-certified steel (in my experience) is about 30%+. A completely unsustainable figure. Therefore without starting with independently certified 11595E steel, using the Mil-Spec MPI program would not be viable.

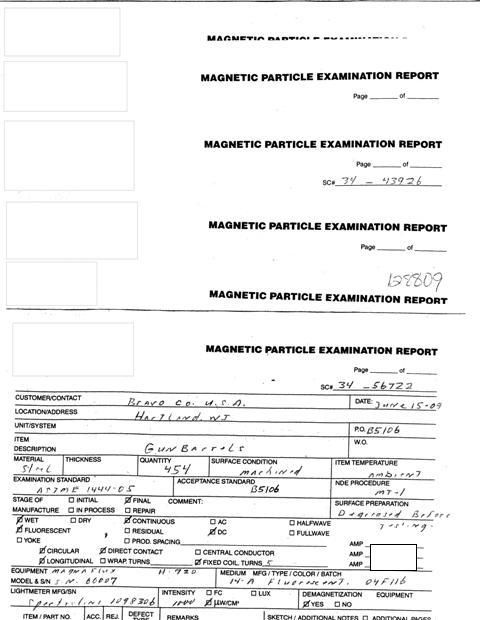

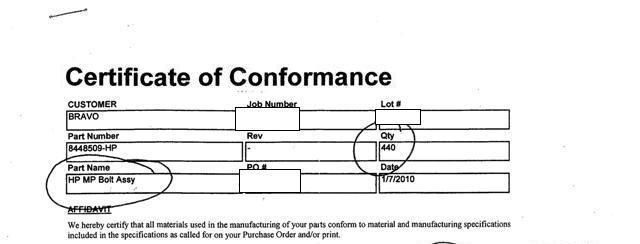

Above is an example of part of a MPI Report. (our IP/Corp info redacted) The ASTME procedure we use shows all the flaws the Mil-Specs want to see. Using a different MPI procedure will reveal fewer flaws and therefore pass more product (and fail less product). I have spent some time in a MPI booth when designing the BCM program and saw the difference. So the procedure used and the rejection criteria used are as important as the test themselves. Number 4 is always outsourced by a certified NDT facility. That procedure has never been brought in house. So #4 cannot be done without #1, And #4 doesn’t mean as much without #2 & #3, And #4 doesn’t mean as much without following the letter of the Milspec. When the rubber meets the road, what does this mean to the average shooter? Quite frankly; maybe not much ? 99% of the commercial market barrels don’t have any of the 1-4 steps in any form, and those rifles are continuing to serve their owners well. If I have a rifle that was a not built to that standard and was running well for me, would I sell it to upgrade to a BCM or similar? No Way. Commercial guns don’t see 1% of the hard use a .mil gun sees. I will never argue that a shooter “needs” the specs of the BCM line up (including 1-4 above, and the others) to have a good carbine. I simply wanted to offer a product that replicated those specs (all details) for shooters who might want it. Regarding the above processes, we have done HPT in house as well as contracted with other companies to supply the service as it relates to both bolts and barrels. Here is an example of a cert on received for the first shipment this year (our IP/Corp info redacted). The tech who receives the product is required to verify count and sku, that is why both are circled. He then signs off on the sheet (which has been cropped out of the pic)

We also have certs for springs referencing wire type, material size, free length, load, chemical composition, tensile strength, plating specs, etc. For roll pins referencing material specs, heat treat, plating, shear tests, etc. But that stuff is not very exciting to most folks. In summary, don’t get all OCD and wrapped around the axle with if your rifle does or doesn’t meet whichever of the specs. If you have run your rifle hard, and it works in the applications you need it to, move on. You are your own judge and jury as to what you need as it relates to your budget and your mission with the rifle. IMHO, you would serve yourself much better by spending that time, effort, and energy in insuring you are proficient with your carbine. All the specs and standards in the world won’t offer much help if you cannot effectively deploy your carbine. This forum and others have a good number of training schools listed. The straight no-BS answer is you will be much farther ahead if you spend more money with those schools and less money with Bravo Co. Thank you for reading, Paul

|

|

|

|

Working man's perspective. Low speed, high drag..not an operator.

During the last panic I sold a pair of vintage Colt Hbars for almost twice what I paid for them... At 52 I couldn't see the sights well and the triggers were terrible. Purchased 3 Spikes lowers and had them built by a local AR15 manufacturer. Quality parts inside, Magpul stocks that fit me well, ACT triggers, Colt 6920 complete upper on one and a Spikes Mid-length complete upper on the other. Both guns run 100% with everything I feed them. I can see the Aimpoint Pro and Magpul sights so much better and ringing steel at 100 yards is not even a challenge. I enjoy shooting these guns. My needs are served much better by the replacements. If you exclude optics, I have less than a grand in each complete rifle. However each part is exactly what I wanted. IMHO that is priceless! YMMV |

|

|

|

if you spend enough, you get to post pics in the MK12 thread... so there's that

|

|

|

|

Quoted:

Working man's perspective. Low speed, high drag..not an operator. During the last panic I sold a pair of vintage Colt Hbars for almost twice what I paid for them... At 52 I couldn't see the sights well and the triggers were terrible. Purchased 3 Spikes lowers and had them built by a local AR15 manufacturer. Quality parts inside, Magpul stocks that fit me well, ACT triggers, Colt 6920 complete upper on one and a Spikes Mid-length complete upper on the other. Both guns run 100% with everything I feed them. I can see the Aimpoint Pro and Magpul sights so much better and ringing steel at 100 yards is not even a challenge. I enjoy shooting these guns. My needs are served much better by the replacements. If you exclude optics, I have less than a grand in each complete rifle. However each part is exactly what I wanted. IMHO that is priceless! YMMV View Quote Why wouldn't you enjoy shooting them. You have quality uppers sitting on your lowers and decent triggers inside them. By the way, they are sitting under $1000 now but if you added a free float rail, a nicer stock and a better trigger, you'd easily be over $1,000. |

|

|

|

|

|

|

|

|

|

Quoted:

Unicorn's post on page 1 pretty much spelled out what is the reality of high vs. low end ARs. I will say that a Yugo will get you from "Point A" to "Point B " just as a Rolls will. However, if you think the quality, reliability, durability and CS of both is the same then you are delusional. Other than that, http://img.photobucket.com/albums/v114/wetidlerjr/SMILEYS/xrockon.png View Quote If you think that because you paid "more" that you will automatically get "better" quality, reliability, durability, and CS then you are too delusional. |

|

|

|

Quoted:

That is not the type of feedback the OP needs here. View Quote View All Quotes View All Quotes Quoted:

My 1:7 ptac upper looks good, it was the $290 complete upper. Haven't had a chance to shoot it yet, tho. That is not the type of feedback the OP needs here. I guess we can see where the priorities lie with most AR owners. |

|

|

|

Personally, I think on average you get what you pay for.

I took the sub 1k route with my ARs, and am happy, and confident they will hold up, but that said, I need to deal with the issues you get when not paying double. My upper and lower fit is shit. I don't care, but it does. Well, now I care since I don't think it's worth SBR'ing a lower I am not sure if it's the problem for fit. My gas port is extra large so it will eat Tula to MilSpec, but this I like. My Free float rail almost lines up. My red dot base it loose, but I can tighten it. My front sight post is not quite vertical. Annoying as hell, I will be cutting it. If I paid for a BCM, or DD, or whatever, any issue I encounter they will fix because it is not what they deliver. So I saved a few and took some risks. Won a few, lost a few. If I had the money, I would pay for a top of the line upper. And I know I am not paying for a logo, but the brand behind it. But my AR budget is slim, so I make due, and deal with whatever comes of it on my own. But now I am building uppers so I get the best of both worlds. |

|

|

|

Quoted:

People pay for names, looks and handguards made entirely of mounting surface that have nothing mounted on them. Nothing wrong with it but it is what it is. View Quote This. Assuming proper spec / built parts. Low cost doesn't necessitate low quality, though low cost can consist of such. That's why a buyer has to do their research. |

|

|

|

Quoted:

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started. http://img.photobucket.com/albums/v445/bravocompanyusa/BCM4%20Lowers/BravoCoMFGlogo.jpg The BCM program was basically designed with the philosophy of “no shortcuts”. Whether the consumer will notice the short cut or not, does not matter; “no shortcuts”. http://img.photobucket.com/albums/v445/bravocompanyusa/Run-it-hard-1205.jpg View Quote Except for the short cuts that go into their rifle (NOT carbine) receiver extensions, which are made from 6061 aluminum vs. the original mil spec 7075. Aside from that short cut, no other short cuts... |

|

|

|

Quoted:

Except for the short cuts that go into their rifle (NOT carbine) receiver extensions, which are made from 6061 aluminum vs. the original mil spec 7075. Aside from that short cut, no other short cuts... View Quote View All Quotes View All Quotes Quoted:

Quoted:

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started. http://img.photobucket.com/albums/v445/bravocompanyusa/BCM4%20Lowers/BravoCoMFGlogo.jpg The BCM program was basically designed with the philosophy of “no shortcuts”. Whether the consumer will notice the short cut or not, does not matter; “no shortcuts”. http://img.photobucket.com/albums/v445/bravocompanyusa/Run-it-hard-1205.jpg Except for the short cuts that go into their rifle (NOT carbine) receiver extensions, which are made from 6061 aluminum vs. the original mil spec 7075. Aside from that short cut, no other short cuts... Ouch! That made me spit a little! You can buy quality parts and build your own and it can be as reliable as te big boys...buy low quality get low quality. Right now you can get good quality for cheap. |

|

|

|

Quoted:

Personally, I think on average you get what you pay for. I took the sub 1k route with my ARs, and am happy, and confident they will hold up, but that said, I need to deal with the issues you get when not paying double. My upper and lower fit is shit. I don't care, but it does. Well, now I care since I don't think it's worth SBR'ing a lower I am not sure if it's the problem for fit. My gas port is extra large so it will eat Tula to MilSpec, but this I like. My Free float rail almost lines up. My red dot base it loose, but I can tighten it. My front sight post is not quite vertical. Annoying as hell, I will be cutting it. If I paid for a BCM, or DD, or whatever, any issue I encounter they will fix because it is not what they deliver. So I saved a few and took some risks. Won a few, lost a few. If I had the money, I would pay for a top of the line upper. And I know I am not paying for a logo, but the brand behind it. But my AR budget is slim, so I make due, and deal with whatever comes of it on my own. But now I am building uppers so I get the best of both worlds. View Quote If you're using a firearm for self-defense the above post is the exact mindset NOT to have. If you can find a good sale on quality proven parts go for it. Don't, however, buy parts simply because they're inexpensive. In this business cheap almost always equates to inferior and for good reason. Quality materials, quality machined parts, quality control, good customer service, and R&D are all expensive endeavors. |

|

|

|

Quoted:Yea but how much better accuracy are we talking, and is it for a precision gun or SHTF gun? View Quote Ill admit i have a nice Daniel Defense with a upgraded trigger. I believe i will never see myself being able to out shoot a cheap m&p 15 from walmart. with a good shooter behind it. If SHTF.....im getting my ak out instead. Also when a company request material data, if it does pass, that doesnt mean there wont be any imperfections in the material before or after it's machines. It does however provide it has a much better chance and does meet their requirements. Benefit of working in quality control at a machine shop ;) |

|

|

|

My mindset is fine. My barrel is fn, feed ramps are perfect, my bolts are gtg and I have only good mags. I have never had a failure from steel case to premium ammo. But because I saved money on a complete assembly from a top brand I have no real recourse for cosmetic issues. And really that is only what I identified. I didn't mean to imply crap parts. I see a lot of boutique rifle builds that offer nothing over what I have. But mil spec BCM definitely does, but I would say that is required for pros, not hd and range work. I know exactly where I drew the line between cost and parts.

I love BCM, DD and will own them, but I doubt I will shoot better with them. I won't trust them anymore than my cmmg or PSA. Oh who am I kidding, I will trust them More. I think crap parts are actually hard to find, but skills are the real issue. Last time at the range, all of a sudden there was down feathers everywhere. The guy with the colt 6920 shot he jacket he was using as a rest. |

|

|

|

Quoted:

Personally, I think on average you get what you pay for. I took the sub 1k route with my ARs, and am happy, and confident they will hold up, but that said, I need to deal with the issues you get when not paying double. My upper and lower fit is shit. I don't care, but it does. Well, now I care since I don't think it's worth SBR'ing a lower I am not sure if it's the problem for fit. My gas port is extra large so it will eat Tula to MilSpec, but this I like. My Free float rail almost lines up. My red dot base it loose, but I can tighten it. My front sight post is not quite vertical. Annoying as hell, I will be cutting it. If I paid for a BCM, or DD, or whatever, any issue I encounter they will fix because it is not what they deliver. So I saved a few and took some risks. Won a few, lost a few. If I had the money, I would pay for a top of the line upper. And I know I am not paying for a logo, but the brand behind it. But my AR budget is slim, so I make due, and deal with whatever comes of it on my own. But now I am building uppers so I get the best of both worlds. View Quote You are being realistic and working withing your budget instead, which is better than avoiding "Colt, BCM, DD, etc" because "you're paying for the brand" or "I hate fanboys". I think you've got the the right mindset. Buy what you can and appreciate the limitations. I'll take this over the "just as good" crowd any day. Upgrade when you can though. You're worth it.

|

|

|

|

Quoted:

So, how do YOU feel this rifle would preform over a 6920 or PSA rifle? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started. So, how do YOU feel this rifle would preform over a 6920 or PSA rifle? Honestly, reading through that description of the BCM rifles, the only thing I see in there that I don't see called out in a PSA $500-600 upper is the description of the forward assist. It all sounds good and I'm sure it is, but it's not like BCM is the only company doing this. My complete kit from Del-ton has the following and cost $490 with a 30 round gen 2 pmag: Barrel: Chrome Moly Vanadium crome lined M4 Feed Ramps 16" Length 1x9 Twist A2 Flash Hider Manganese Phosphated Phosphated under Front Sight Base Taper Pins in F-marked Front Sight Base Threaded Muzzle Mid Length Heavy Barrel Chamber: 5.56 X 45 mm Bolt And Carrier: Phosphated 8620 Steel Carrier Assembly Carpenter 158 Bolt HPT/MPI Tested Heat Treated and Plated Mil-Spec Chrome Lined Carrier Interior Carrier Key - Chrome Lined, attached with Grade 8 Screws Properly Staked & Sealed Gas Key Handguards: Mid Length Aluminum Delta Ring Single Heat Shield Upper Receiver: Forged 7075 T6 Aluminum A3 Flat Top with M4 Feed Ramps engraved T marks Hard Coat Anodized Mil-Spec Ejection Port Cover and Round Forward Assist Right Hand Ejection Bore's surface is coated with dry film lube, over the anodized surface |

|

|

|

Quoted:

So, how do YOU feel this rifle would preform over a 6920 or PSA rifle? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started. So, how do YOU feel this rifle would preform over a 6920 or PSA rifle? probably preform the same as the 6920. PSA is a crapshoot. |

|

|

|

Quoted:

probably preform the same as the 6920. PSA is a crapshoot. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Here is what you're paying for when purchasing an AR from a reputable company.This was posted by BCM back in 2006 when they first started. So, how do YOU feel this rifle would preform over a 6920 or PSA rifle? probably preform the same as the 6920. PSA is a crapshoot. Out of curiosity, what makes PSA a crapshoot? |

|

|

|

|

|

Quoted:

I haven't paid close attention in a little while, but there was a stretch where PSA was sending out mis-assembled uppers and the wrong parts (i.e. carbine gassed barrels when you ordered a mid-length gas one). View Quote View All Quotes View All Quotes Quoted:

Quoted:

Out of curiosity, what makes PSA a crapshoot? I haven't paid close attention in a little while, but there was a stretch where PSA was sending out mis-assembled uppers and the wrong parts (i.e. carbine gassed barrels when you ordered a mid-length gas one). Oh. Hadn't heard that. I'm a relative newcomer and it seems like lately in the build forum everyone recommends PSA highly with the exception of the P-tac stuff, which even then most agree it was issues last year that seem to have been resolved. I have a Del-ton kit, plan to buy a JP-15 lower and upper later this year and have three lowers that I was planning to fill out mostly with PSA and Spikes uppers. I figure any kit or upper I get is gonna get the once over before I fire it even if they say it's heaspaced and test fired. |

|

|

|

To me, it's about quality, fit, and finish. Comparison:

You can buy a 50" LED Samsung TV for $850 or a Sylvania 50" LED TV for $600 bucks. Sure, they both show a 1080P picture (both go boom) but the quality, reliability and look (brightness etc) aren't comparable. Really though, it depends what you're comparing. $$$ to $? $$$ to $$? 3 to 1 isn't close. 2-1 or 3-2 is where you start looking at value and what you want. |

|

|

|

Long time lurker, first time poster here. Just wanted to add my 2 pennies to the discussion. I have a Bushmaster ACR that cost me $2200. I wanted a low cost AR as a "beater" rifle and one that I can easily find parts for if necessary, so I've recently picked up a Core 15 M4 Scout for $700.

Perhaps a more experienced shooter can tell the difference between the two as far as accuracy is concerned, but at the distances I'm shooting, they both do the same thing. I aim, pull the trigger, both rifles go bang, both rifles equally effective at getting a 62 grain projectile to hit the designated target. I've only had about 50 rounds down the Core 15 so I can't speak to it's reliability yet, but so far no hints suggesting less than adequate reliability. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.