|

I had the same problem with my new oven. But there was no sheetrock on the wall (oven set into enclosure) and I was able to remove the entire outlet box and move it to a new location where the oven cord could reach. No splicing needed.

|

|

|

|

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ?

I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here |

|

|

|

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here View Quote |

|

|

|

|

|

|

|

Any room inside of the back panel of the stove to install a junction box?

Would it be okay to extend the wire from a junction box inside of the stove, instead of inside of the wall? |

|

|

|

Wire tap connectors are what we used for ac rooftops when we needed more wire. We had used large wire nuts, but they sometimes would burn up , blocks like these didn't.

https://www.amazon.com/Morris-97017-Products-Insulated-Connector/dp/B00UKG81GO |

|

|

|

Diagram added to OP. I'm thinking the two unused boxes might have unused 220 runs for this very situation?

|

|

|

|

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here View Quote |

|

|

|

|

|

Quoted:

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here  220/221 Volts Whatever it takes? |

|

|

|

Quoted:

Diagram added to OP. I'm thinking the two unused boxes might have unused 220 runs for this very situation? View Quote Assuming you are simply wanting to raise the junction box and not go horizontally at all, just cut-in a new box above where you want it. For the wiring, do one of the following: -fish a short piece of new cable between the boxes to extend to the new location. Wirenut the wires in the lower box with adequately rated wire nuts. If wire is aluminum verify that the wirenuts are rated for aluminum as most are not. Blank off the bottom j-box. -pull back the exisiting wire from within the wall and put it in the new box. You can reach in the wall somewhat through the old and new box holes to remove any potential cable staples. The hole for the old box can be covered by installing the old box (or get a new one) back in the wall and then blank it off. To connect the oven: -get a stainless blank plate and punch/drill a 7/8" hole (for 1/2" connectors) or a 1-1/8" (for 3/4") and connect flex to plate with a 90 degree fitting. Then wirenut (see above for precautions) as required and intaall plate. -install a properly rated receptacle to plug in the cord. I do believe that your unit has a piece of flex though. I recommend using a 2-gang box for your new box. More room for splicing and tucking wires back into the wall... |

|

|

|

Quoted:

Quoted:

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here  ... ...

|

|

|

|

I’m not an electrician, but can’t you cut a hole in the wall where you need the connection to be, reach in and grab the wire and back pull it up to the new box location? Unless the wiring was run through the slab or bottom plate of a 2 story. Make sure to trip the breaker before- know what, call an electrician.

|

|

|

|

Could you move some breakers around in your panel to get enough slack to move the box up to reach? Because a 1'-2' patch/extension would be a no go here. That is a fire waiting to happen.

|

|

|

|

|

|

Quoted:

https://www.AR15.Com/media/mediaFiles/384478/A6363AB9-0209-4CFF-8552-68AF6550C334-606381.jpg Get’r done. View Quote |

|

|

|

Quoted:

Do I really need the electrical tape? ETA: All the difference in the world between $13p/hr vs $15p/hr. |

|

|

|

Quoted:

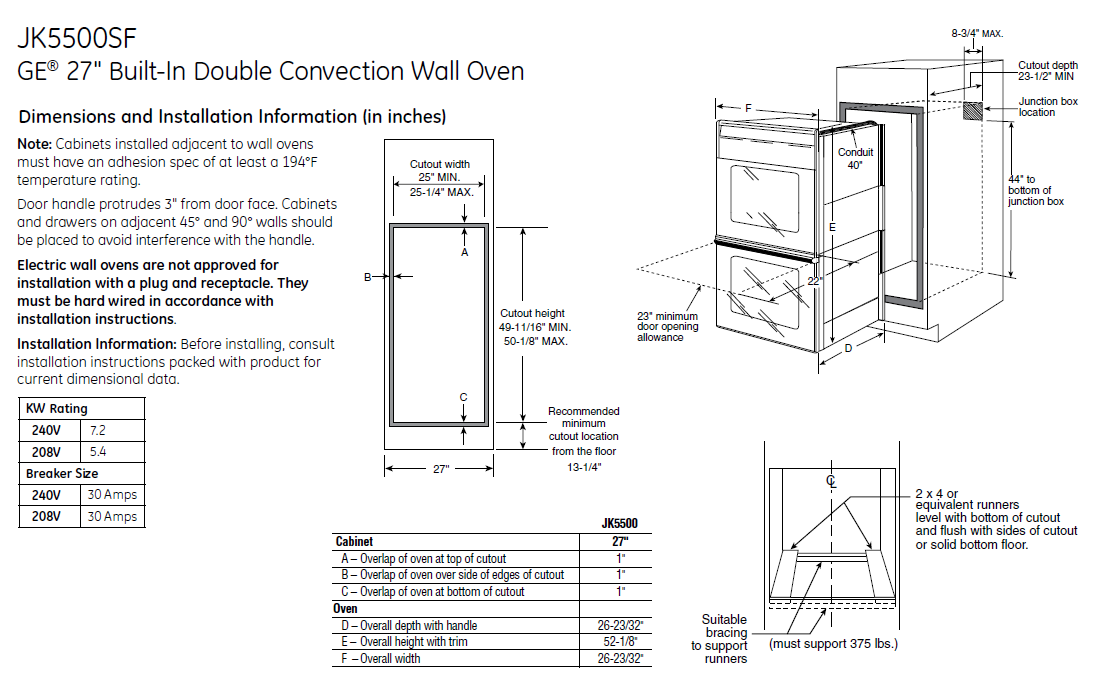

So my new double wall oven's power lead does not reach my junction box that the old one reached. My thoughts are I can install a new junction box and splice with metal conduit and same gauge wire to the old junction box? The oven: GE Double Wall Oven https://www.AR15.Com/media/mediaFiles/199435/IMG_20180713_114330-606231.JPG EDIT: Im thinking now maybe the top tow capped blue boxes might have 220 wire, that just needs to be connected at the panel. View Quote

1 - turn off breaker 2 - test that power off at current box 3 - cut hole in wall where new box location desired 4 - pull wires up from current box, to new hole 5 - install new box 6 - splice oven wires to new box/wires 7 - install oven 8 - use new oven |

|

|

|

Quoted: https://www.AR15.Com/media/mediaFiles/199435/IMG_20180713_114330-606231.JPG https://s33.postimg.cc/5x7zotocv/jthomps123.png 1 - turn off breaker 2 - test that power off at current box 3 - cut hole in wall where new box location desired 4 - pull wires up from current box, to new hole 5 - install new box 6 - splice oven wires to new box/wires 7 - install oven 8 - use new oven View Quote

|

|

|

|

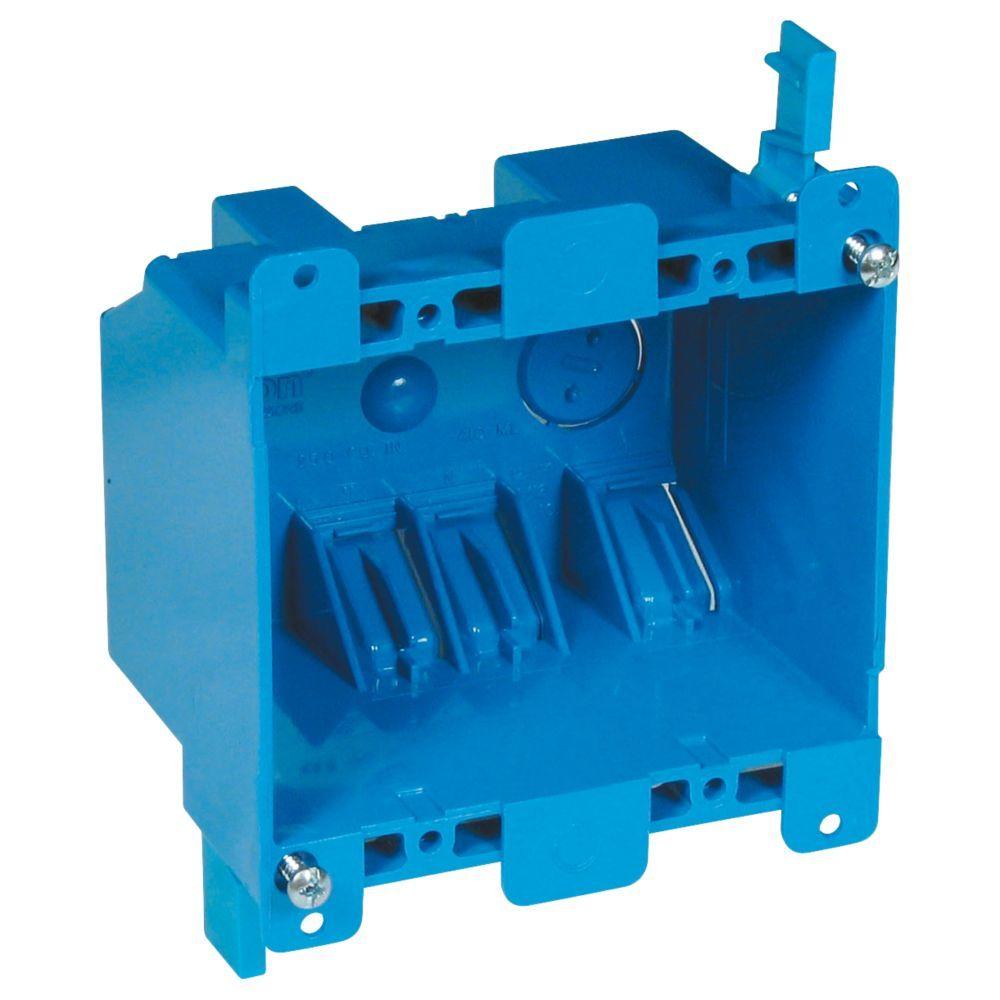

Go to HomeDepot and check out "Old Work" boxes.

You may be able to recess the current box...install new box up higher...then run wire between the two. Verify that the connection in the old box is according to approved methods if such a connection is legit. Other issues may be relevant that this non-electrician is unaware of. The following may not be the correct style box and does not appear to need to be by a stud One example

Does the current box that is too low look this this:

|

|

|

|

Quoted:

Do I really need the electrical tape? |

|

|

|

Quoted:

Do I really need the electrical tape?

You don't want to spill electricity everywhere, do you? |

|

|

|

Quoted:

NO! And do not splice like that photo shows... View Quote View All Quotes View All Quotes Quoted:

Quoted:

Do I really need the electrical tape? |

|

|

|

Quoted:

Uh... yeah.

You don't want to spill electricity everywhere, do you? View Quote View All Quotes View All Quotes Quoted:

Quoted:

Do I really need the electrical tape?

You don't want to spill electricity everywhere, do you? |

|

|

|

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here View Quote |

|

|

|

|

|

Quoted:

Go to HomeDepot and check out "Old Work" boxes. You may be able to recess the current box...install new box up higher...then run wire between the two. Verify that the connection in the old box is according to approved methods if such a connection is legit. Other issues may be relevant that this non-electrician is unaware of. The following may not be the correct style box and does not appear to need to be by a stud One example https://images.homedepot-static.com/productImages/1e3c4d7c-1c41-4409-a1f0-acf3c29785e1/svn/boxes-brackets-b225r-upc-64_1000.jpg Does the current box that is too low look this this: https://images.homedepot-static.com/productImages/3dbc9b89-e710-496f-b4e9-b39320d787ec/svn/boxes-brackets-521711234ew-25r-64_1000.jpg View Quote |

|

|

|

You can for extra insurance or just stick a bucket underneath. Check it periodically for electrons to see if there's a leak.

|

|

|

|

Quoted:

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here I think tradesmen in different parts of the country refer to it in their own way |

|

|

|

Quoted:

Guess you want the $13.00p/hr guy. Cheap bastard. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Do I really need the electrical tape?  ... ...

|

|

|

|

|

|

Quoted:

install a 220 recep in the wall and use an appliance cord, never worry about wire nuts again. View Quote All ovens/ranges now do not come with cords. The cords are to be cut/installed at delivery to ensure proper length. Edit: My post is for standalone range/oven combos. Not built in wall units. |

|

|

|

Quoted:

Any competent electrician knows that standard household service is 110/220- single phase just the same as 120/240 single phase. There is no difference. I personally never roped a house in 15 yrs of electric work. Was a heavy industrial electrician mainly working with 480 3 phase. I think tradesmen in different parts of the country refer to it in their own way View Quote View All Quotes View All Quotes Quoted:

Quoted:

Quoted:

Seems odd that an appliance manufacturer has the L1 L2 terminal block inside the chassis in a place that is not readily accessible ? I would simply replace the elec cord with similar gauge ( longer ) and then hook up to a 220V plug that matches your current receptacle Ex IBEW electrician here I think tradesmen in different parts of the country refer to it in their own way |

|

|

|

Quoted:

https://www.AR15.Com/media/mediaFiles/199435/IMG_20180713_114330-606231.JPG https://s33.postimg.cc/5x7zotocv/jthomps123.png 1 - turn off breaker 2 - test that power off at current box 3 - cut hole in wall where new box location desired 4 - pull wires up from current box, to new hole 5 - install new box 6 - splice oven wires to new box/wires 7 - install oven 8 - use new oven View Quote View All Quotes View All Quotes Quoted:

Quoted:

So my new double wall oven's power lead does not reach my junction box that the old one reached. My thoughts are I can install a new junction box and splice with metal conduit and same gauge wire to the old junction box? The oven: GE Double Wall Oven https://www.AR15.Com/media/mediaFiles/199435/IMG_20180713_114330-606231.JPG EDIT: Im thinking now maybe the top tow capped blue boxes might have 220 wire, that just needs to be connected at the panel. https://s33.postimg.cc/5x7zotocv/jthomps123.png 1 - turn off breaker 2 - test that power off at current box 3 - cut hole in wall where new box location desired 4 - pull wires up from current box, to new hole 5 - install new box 6 - splice oven wires to new box/wires 7 - install oven 8 - use new oven |

|

|

|

Quoted:

does the wire enter the box from the back? bottom? maybe you can open wall and get enough slack to move box up View Quote Wouldn't even have to patch the Sheetrock as no one would see it. |

|

|

|

|

|

OK so heres the deal after pulling the oven back out to wire it up:

There are two blue gang-boxes up top, both were covered with empty plates. The top box has unused wire in it, when I test for voltage I cant find any although there is a 240 breaker in my box labeled "spare". The second box is empty, it seems likely it was cut and moved down through the wall an wired externally to the lower junction box. It appears I have 2 'easy' options. #1: Find where the top box wire terminates and wire it up there. Not sure how to even do this, there are no non-connected wires in my breaker box. So either its not wired into the box or im failing at testing voltage on the wall side. #2: Go with my original plan. Use the existing junction box, use metal conduit and wire it up into the top cavity and install a new junction box, then wire stove whip into new box. Thoughts? Also, if i was to get the top box wired, how do I terminate metal conduit into is? Is that even the correct way? Another thing, the feeder wire is 3 wires? I've stumbled across a site that says splices/extensions can only be done with 4 line wire? |

|

|

|

Quoted:

OK so heres the deal after pulling the oven back out to wire it up: There are two blue gang-boxes up top, both were covered with empty plates. The top box has unused wire in it, when I test for voltage I cant find any although there is a 240 breaker in my box labeled "spare". The second box is empty, it seems likely it was cut and moved down through the wall an wired externally to the lower junction box. It appears I have 2 'easy' options. #1: Find where the top box wire terminates and wire it up there. Not sure how to even do this, there are no non-connected wires in my breaker box. So either its not wired into the box or im failing at testing voltage on the wall side. #2: Go with my original plan. Use the existing junction box, use metal conduit and wire it up into the top cavity and install a new junction box, then wire stove whip into new box. Thoughts?https://www.AR15.Com/media/mediaFiles/199435/IMG_20180715_094827-608264.JPG Also, if i was to get the top box wired, how do I terminate metal conduit into is? Is that even the correct way? View Quote That upper box and its wire looks to be a non-option. Regarding how to connect the oven to a box: Buy a metal blank plate and drill/punch a properly sized hole in it. Your flex size will predicate the hole size needed. For a 1/2" connector you'll need a 7/8" hole & for a 3/4" connector you'll need a 1-1/8" hole. A simple, safe way to drill a plate is to mount the plate to a spare/loose box and hold it between your feet on the ground. The torque put on the plate will be a booger so I wouldn't attempt to hold it with your hands. Either use a uni-bit (step bit) or a knockout punch. Hopefully you have access to one of those? If not, look for a metal plate that has a prepunched 1/2" knockout already. Simply remove the knockout, connect the fitting, wirenut the wires & install the plate... |

|

|

|

Quoted:

I am not an electrician and it is late but usually you dont run romex in conduit and you definitely dont expose it. View Quote Especially behind an appliance. Use existing junction bow to make splice using split bolts for the wire size. Short piece of NM cable in matching size to new box. There are numerous ways to attach the new box including drywall 'hangers' and clamps of various designs. Or just cut a clean hole from stud to stud behind the stove and put in a wood or metal bar to mount the new junction box. If you do a neat job cutting you can then use the removed piece to fill in the hole beside the new box. Tape and mud with setting compound and be done in one day. It is is hidden behind the new stove it does not have to be perfect. |

|

|

|

This image from above states 40" conduit.

Why not open the rear oven cover panels, remove the 4 ring crimp connectors from the terminal block and replace the 40" conduit with whatever lenth conduit you need? I usually wrap the metal conduit with electrical tape so the conduit doesnt "sing" when the fans are running and vibrating. https://s33.postimg.cc/5x7zotocv/jthomps123.png |

|

|

|

Quoted:

220/240 is a little different than a car stereo. Your splice could be interpreted as a little twist and some duct tape by the "craftsman" here. That could be a disaster. View Quote View All Quotes View All Quotes Quoted:

Quoted:

Splice the cord Cut your cord and splice it is what I’d do. Shouldn’t be a problem. I’m a substation electrician and we splice cables all the time. Never had an issue with a properly spliced cable.. |

|

|

|

Oy vey, do you want to fuck around with the rough runs? If yes go move the run or pull a new one.

If no, piggy a new junction off the old. It's not like this hasn't been done to add receptacles to 220 circuits a billion times. I minimize attic time so I'd go for the latter. |

|

|

|

Quoted:

This image from above states 40" conduit. Why not open the rear oven cover panels, remove the 4 ring crimp connectors from the terminal block and replace the 40" conduit with whatever lenth conduit you need? I usually wrap the metal conduit with electrical tape so the conduit doesnt "sing" when the fans are running and vibrating. https://s33.postimg.cc/5x7zotocv/jthomps123.png View Quote Also what is the proper way to attach the ground? The old wire I will use has solid core copper, current wire is stranded attached with 4 ring crimp. Thanks! @Laserjock. |

|

|

|

So I ended up going to Lowes and purchasing some thhn 10 gauge copper strand and ring terminals to rebuild the oven whip to 6'. Utilizing the old metal conduit. Perfect fit.

Right now doing a 1 hr burn in on both ovens @ 400F, fingers crossed! Thanks for all the help everyone! I really do appreciate all the input. |

|

|

Win a FREE Membership!

Win a FREE Membership!

Sign up for the ARFCOM weekly newsletter and be entered to win a free ARFCOM membership. One new winner* is announced every week!

You will receive an email every Friday morning featuring the latest chatter from the hottest topics, breaking news surrounding legislation, as well as exclusive deals only available to ARFCOM email subscribers.

AR15.COM is the world's largest firearm community and is a gathering place for firearm enthusiasts of all types.

From hunters and military members, to competition shooters and general firearm enthusiasts, we welcome anyone who values and respects the way of the firearm.

Subscribe to our monthly Newsletter to receive firearm news, product discounts from your favorite Industry Partners, and more.

Copyright © 1996-2024 AR15.COM LLC. All Rights Reserved.

Any use of this content without express written consent is prohibited.

AR15.Com reserves the right to overwrite or replace any affiliate, commercial, or monetizable links, posted by users, with our own.